Organic-inorganic composite type high-temperature proton exchange membrane used for fuel cell and preparation method for proton exchange membrane

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems affecting the overall performance of high temperature proton exchange membrane fuel cells, low proton conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing an organic-inorganic composite high-temperature proton exchange membrane for a fuel cell, comprising the following steps:

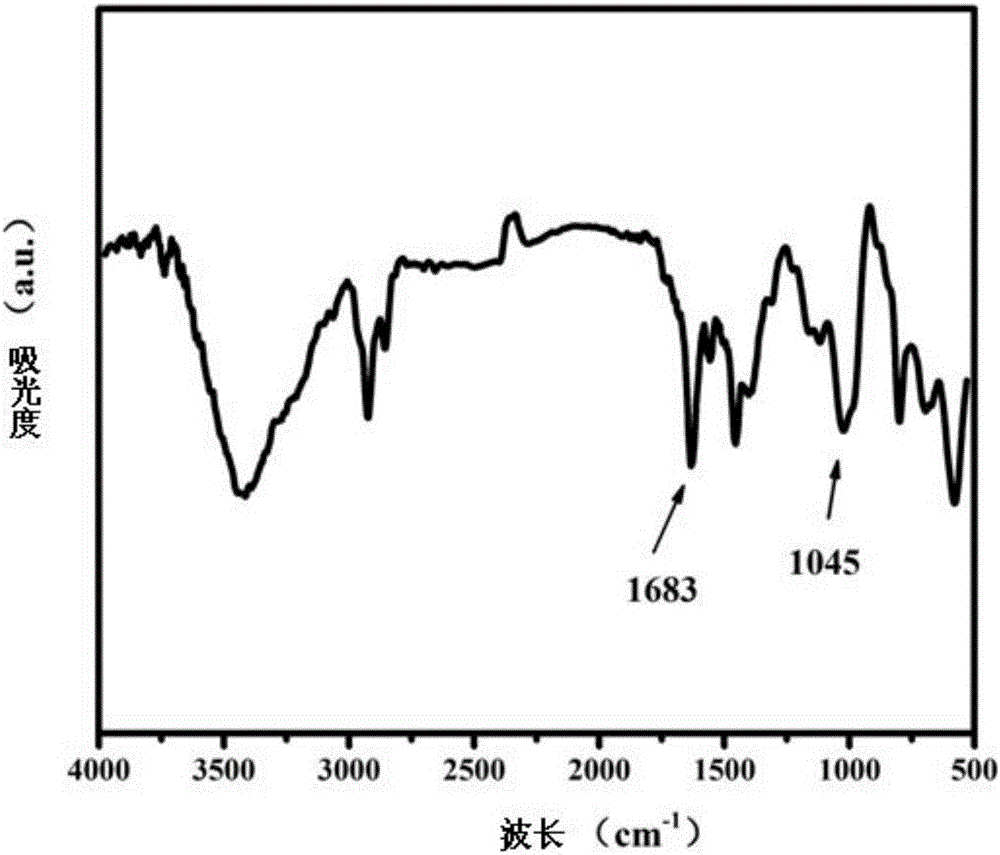

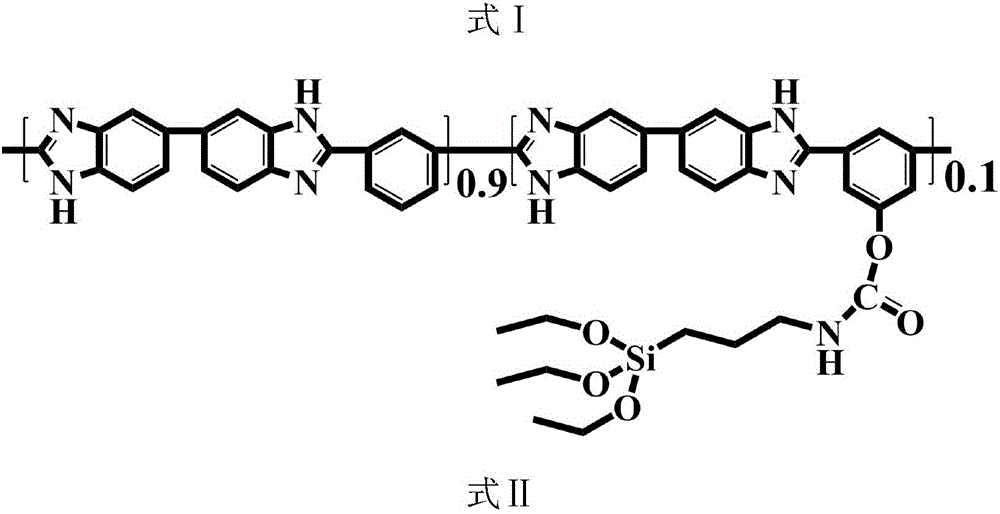

[0035] Step 1: Dissolve polybenzimidazole containing hydroxyl groups in an organic solvent, then add a silane coupling agent with isocyanate groups and a catalyst, and react at 60-80°C for 48-72 hours to obtain a polybenzimidazole with siloxane The polybenzimidazole solution of alkyl side group;

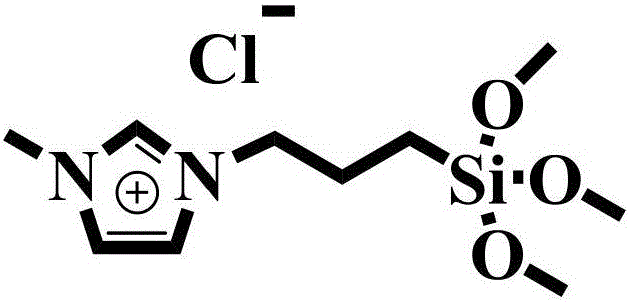

[0036] Step 2: Add an ionic liquid functionalized silicon dioxide precursor to the polybenzimidazole solution with siloxane side groups obtained in Step 1, and stir for 6 to 12 hours to obtain a film-forming liquid. The film-forming liquid The weight percentage of polybenzimidazole containing ionic liquid functionalized silicon dioxide precursor and siloxane side group is (3-12%): (88-97%);

[0037] Step 3: The film-forming solution obtained in Step 2 is salivated to form a film, and the obtained...

Embodiment 1

[0049] The preparation method of hydroxyl-containing polybenzimidazole is: under nitrogen protection, polyphosphoric acid is added as a solvent in a four-necked flask, and 0.1mol 3,3',4,4'-tetraaminobiphenyl is added after heating for 2 hours. After mixing evenly, add 0.09mol 1,3-isophthalic acid and phosphorus pentoxide. After mixing again, raise the temperature to 190°C and continue the reaction for 2 hours. After cooling down, add 0.01mol hydroxyisophthalic acid and phosphorus pentoxide Diphosphorus, after mixing evenly, raise the temperature to 190°C again, continue to react for 30 hours, pour a small amount of phosphoric acid and continue to react for 20 hours, pour into water to obtain hydroxyl-containing polybenzimidazole. Wherein a=0.1~0.9.

Embodiment 2

[0051] The preparation method of hydroxyl-containing polybenzimidazole is: under nitrogen protection, polyphosphoric acid is added as a solvent in a four-necked flask, and 0.9mol 3,3',4,4'-tetraaminobiphenyl is added after heating for 1 hour. After mixing evenly, add 0.81mol 1,3-isophthalic acid and phosphorus pentoxide. After mixing evenly again, raise the temperature to 200°C and continue the reaction for 1 hour. After cooling down, add 0.01mol hydroxyisophthalic acid and phosphorus pentoxide Diphosphorus, after mixing evenly, raise the temperature to 200°C again, continue to react for 20 hours, pour a small amount of phosphoric acid and continue to react for 10 hours, pour into water to obtain hydroxyl-containing polybenzimidazole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com