Twin-wire separation resistance type molten metal liquid level sensor

A liquid level sensor and molten metal technology, applied in the field of sensing and detection, can solve the problems of low measurement accuracy, limited application range, easy corrosion, etc., and achieve the effects of high measurement accuracy, large measurement range and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

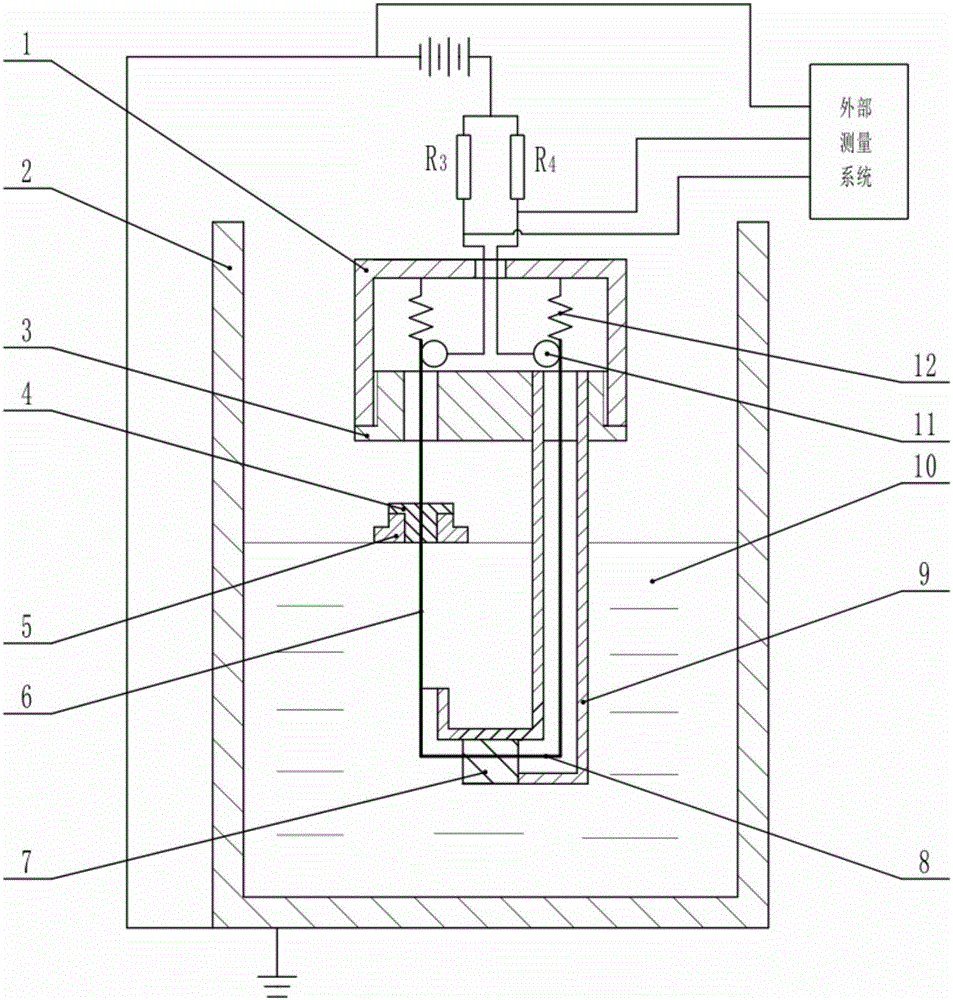

[0024] This embodiment is a double-wire separation resistive molten metal liquid level sensor.

[0025] refer to figure 1 In this embodiment, the double-wire separation resistive molten metal liquid level sensor consists of a sensor protection housing 1, a housing cover 3, a high-temperature sealant 7, a corundum tube 9, a copper contact 11, a spring 12, and ceramic fiber paper 4. Composed of corundum ring 5 and resistance wire; the sensor protection shell 1 and the shell cover 3 are installed in the metal crucible 2 through threaded connection; wherein, the sensor protection shell 1 is an inverted U-shaped structure, and a through hole is processed in the middle of the top , The inner side wall of the open end of the sensor protection housing 1 is processed with threads; The corundum tube 9 is a hollow L-shaped tube, one end of the corundum tube 9 is fixedly connected with a through hole on the casing cover 3, and the other end of the corundum tube 9 is an open end.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com