Composite metal material, its preparation method and metal material product

A composite metal material and metal material technology, applied in metal rolling, metal layered products, chemical instruments and methods, etc., can solve the problems of low yield of kitchenware products, separation of aluminum layer and steel layer, etc., to ensure interface bonding Strength, avoidance of separation, inhibition of interdiffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

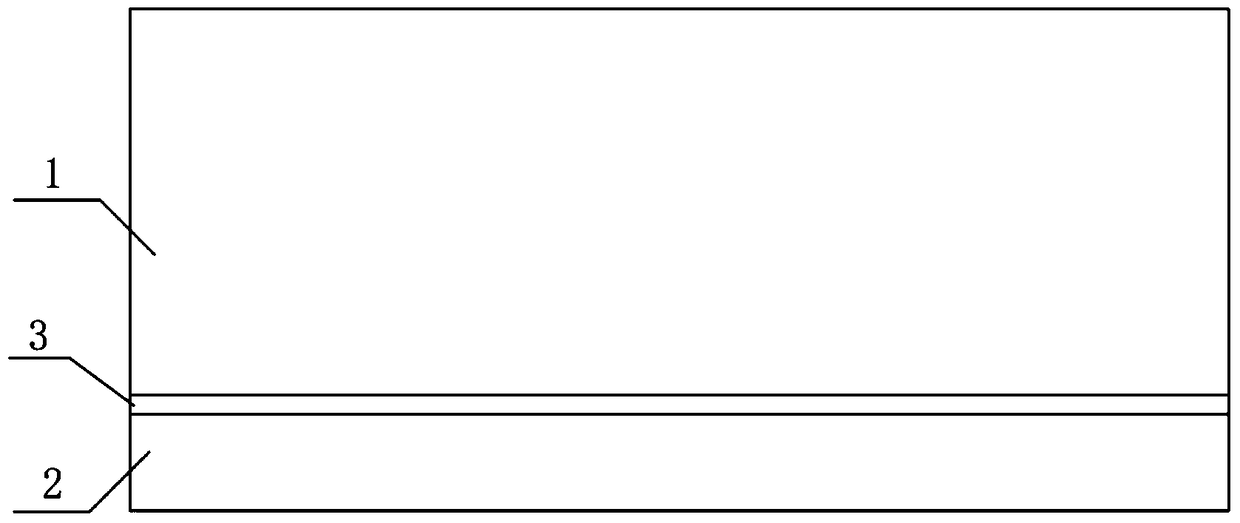

[0037] The composite metal material in this embodiment includes a first alloy layer 1 , a second alloy layer 2 and a third alloy layer 3 located between the first alloy layer 1 and the second alloy layer 2 .

[0038] The first alloy layer is 3003 aluminum alloy, and the 3003 aluminum alloy includes 100 parts by mass of the following materials: copper (Cu) 0.13 parts, manganese (Mn) 1.2 parts, iron (Fe) 0.6 parts, silicon (Si) 0.5 parts parts, zinc (Zn) 0.08 parts, and the rest are aluminum and inevitable impurity elements.

[0039] The second alloy layer is 430 stainless iron, which includes 100 parts by mass of the following materials: 16.8 parts of chromium (Cr), 0.10 parts of carbon (C), 0.7 parts of silicon (Si), and 0.7 parts of manganese (Mn) 1 part, phosphorus (P) 0.03 part, sulfur (S) 0.02 part, and the rest are iron and inevitable impurity elements.

[0040] The third alloy layer is 4A60 aluminum alloy, and the 4A60 aluminum alloy includes 100 parts by mass of the fo...

Embodiment 2

[0048] The composite metal material in this embodiment includes a first alloy layer, a second alloy layer, and a third alloy layer located between the first alloy layer and the second alloy layer, and the composition of the corresponding alloy layer is the same as that in Embodiment 1.

[0049] The preparation method of the composite metal material comprises the following steps:

[0050] First, 3003 aluminum alloy and 4A60 aluminum alloy are hot-rolled and compounded, and the cladding ratio of 4A60 is 10%;

[0051] When rolling and compounding with 430 stainless iron, the surface of the acid-alkali washed stainless iron plate is polished with a roller brush and then rolled and compounded with the 4A60 aluminum alloy surface of the 3003 aluminum alloy / 4A60 aluminum alloy clad plate. The rolling temperature is 200 ℃, rolling speed 4m / min, reduction rate 25%;

[0052] Then, the finished product is annealed, and the annealing system is 320°C, and the temperature is kept for 2h. ...

Embodiment 3

[0055] The composite metal material in this embodiment includes a first alloy layer, a second alloy layer, and a third alloy layer located between the first alloy layer and the second alloy layer, and the composition of the corresponding alloy layer is the same as that in Embodiment 1.

[0056] The preparation method of the composite metal material comprises the following steps:

[0057] First, 3003 aluminum alloy and 4A60 aluminum alloy are hot-rolled and compounded, and the cladding ratio of 4A60 is 5%;

[0058] When rolling and compounding with 430 stainless iron, the surface of the acid-alkali washed stainless iron plate is polished with a roller brush and then rolled and compounded with the 4A60 aluminum alloy surface of the 3003 aluminum alloy / 4A60 aluminum alloy clad plate, and the rolling temperature is 400 ℃, rolling speed 4m / min, reduction rate 25%;

[0059] Then, the finished product is annealed, and the annealing system is 350°C, and the temperature is kept for 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com