Modified impact-resistant co-polypropylene for mute drainage pipeline, and preparation method thereof

A technology of copolymerized polypropylene and drainage pipes, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problem that the Vicat softening temperature cannot meet the requirements, and achieve the effects of protecting life and property, reducing the spread of fire, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

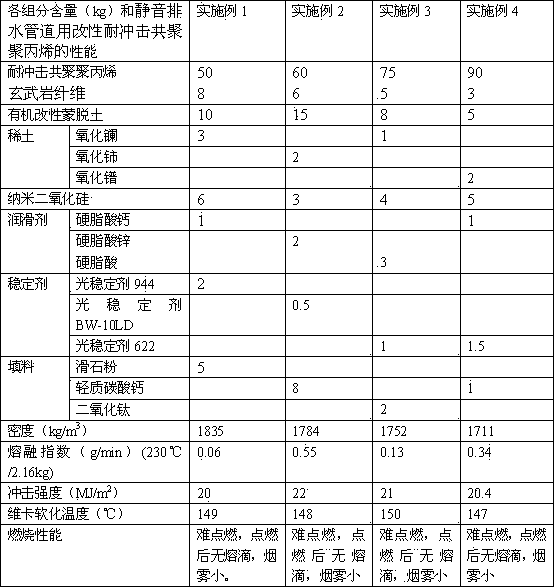

Examples

Embodiment 1

[0026] First, the impact-resistant copolymerized polypropylene, basalt fiber, organically modified montmorillonite, lanthanum oxide, nano-silica, calcium stearate, light stabilizer 944, and talcum powder are evenly mixed according to the proportion of each component in Table 1 , and then extrude the pellets in a twin-screw mixing extruder, the temperature of the extruder is about 150°C, and the rotation speed is 600 rpm.

[0027] Among them, the melt index of impact-resistant polypropylene is 0.05g / 10min, the diameter of basalt fiber is 2μm, the particle size of nano-silica is 60nm, and the particle size of lubricant, stabilizer and filler is less than 20μm.

Embodiment 2

[0029] First, the impact-resistant copolymer polypropylene, basalt fiber, organically modified montmorillonite, cerium oxide, nano-silica, zinc stearate, light stabilizer BW-10LD, and light calcium carbonate were prepared according to the components in Table 1. The proportioning ratio is evenly mixed, and then extruded and pelletized in a twin-screw mixing extruder, the temperature of the extruder is about 220°C, and the rotation speed is 200 rpm.

[0030] Among them, the melt index of impact-resistant polypropylene is 0.5g / 10min, the diameter of basalt fiber is 5μm, the particle size of nano-silica is 20nm, and the particle size of lubricant, stabilizer and filler is less than 20μm.

Embodiment 3

[0032] First impact-resistant polypropylene, basalt fiber, organically modified montmorillonite, lanthanum oxide, nano-silica, stearic acid, light stabilizer 622, and titanium dioxide are uniformly mixed according to the proportion of each component in Table 1, and then Extrude the pellets in a twin-screw mixing extruder, the temperature of the extruder is about 180°C, and the rotation speed is 400 rpm.

[0033] Among them, the melt index of impact-resistant copolymerized polypropylene is 0.1g / 10min, the diameter of basalt fiber is 0.5μm, the particle size of nano-silica is 40nm, and the particle size of lubricant, stabilizer and filler is less than 20μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com