High-temperature-resistant and low-expansion adhesive sealant for filter cartridge

A bonding and sealing, high temperature resistant technology, applied in non-polymer adhesive additives, adhesives, adhesive additives, etc., to achieve the effect of reducing dosage and curing time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

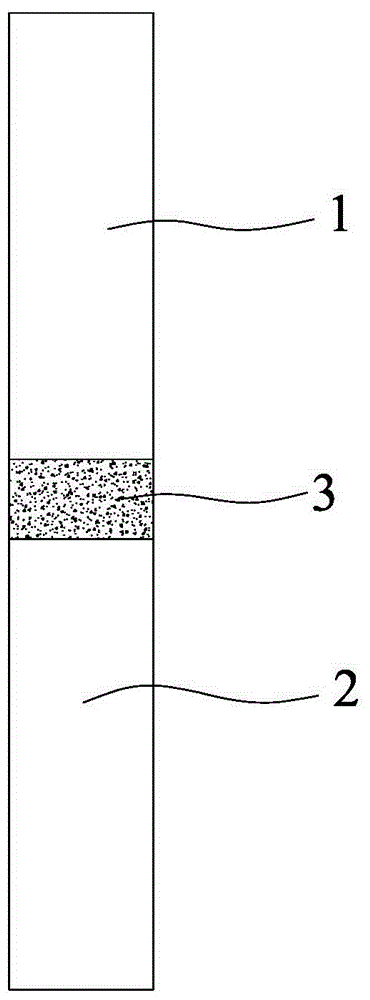

Image

Examples

Embodiment 1

[0019] The dynamic viscosity at 25°C is 10000mPa·sα, ω-dihydroxypolydimethylsiloxane, polydimethylmethylvinylsiloxane with a molecular weight of 5000 and a vinyl content of 0.30%, and a molecular weight of 20000 with terminal hydroxyl poly( A mixture of methyl 3,3,3-trifluoropropyl) siloxane as the base polymer;

[0020] It is composed of nano-magnesia with an average particle size of 20nm and accounting for 10% of the total powder after high-temperature calcination and dehydration, and barium titanate, manganese oxide and sodium silicate with an average particle size of 4 μm and accounting for 90% of the total powder. mixture as a powder;

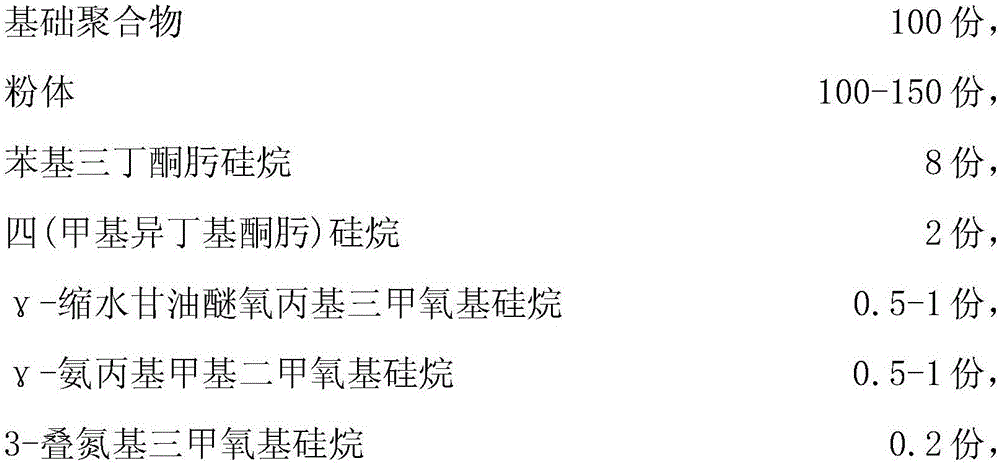

[0021] The specific mass ratio of adhesive sealant is:

[0022]

Embodiment 2

[0024] The dynamic viscosity at 25°C is 20000mPa·sα, ω-dihydroxypolydimethylsiloxane, polydimethylmethylvinylsiloxane with a molecular weight of 10000 and a vinyl content of 0.23%, and a molecular weight of 5000 with terminal hydroxyl poly( A mixture of methyl 3,3,3-trifluoropropyl) siloxane as the base polymer;

[0025] It is composed of nano-magnesia with an average particle size of 50nm and accounting for 20% of the total powder after high-temperature calcination and dehydration, and barium titanate, manganese oxide and sodium silicate with an average particle size of 1 μm and accounting for 80% of the total powder. mixture as a powder;

[0026] The specific mass ratio of adhesive sealant is:

[0027]

[0028]

Embodiment 3

[0030] The dynamic viscosity at 25°C is 15000mPa·sα, ω-dihydroxypolydimethylsiloxane, polydimethylmethylvinylsiloxane with a molecular weight of 8000 and a vinyl content of 0.23%, and a molecular weight of 10000 terminal hydroxyl poly( A mixture of methyl 3,3,3-trifluoropropyl) siloxane as the base polymer;

[0031] It is composed of nano-magnesia with an average particle size of 30nm and accounting for 20% of the total powder after high-temperature calcination and dehydration, and barium titanate, manganese oxide and sodium silicate with an average particle size of 2 μm and accounting for 80% of the total powder. mixture as a powder;

[0032] The specific mass ratio of adhesive sealant is:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com