PP (polypropylene) composite for thin-walled automobile bumper and preparation method of PP composite

A technology for automobile bumpers and composite materials, which is applied in the fields of thin-walled automobile bumper polypropylene composite materials and its preparation, functional polypropylene materials and its preparation, and can solve the problem of large single-piece product size and reduced material shrinkage , high grammage, etc., to achieve the effects of small linear thermal expansion coefficient, low linear thermal expansion coefficient, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

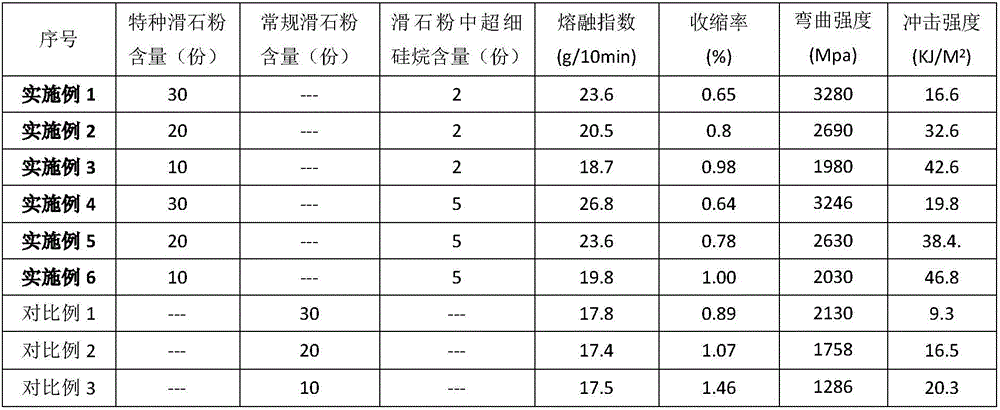

Examples

Embodiment 1

[0034] (1) Preparation of modified special talcum powder:

[0035] According to parts by weight, add 98 parts of special talc powder with mesh number of 3000 mesh and diameter-to-thickness ratio of 30:1; 2 parts of silane dispersant, and mix them together in a high-speed kneader for 3 hours at a speed of 500 r / min .

[0036] (2) Preparation of a polypropylene composite material for thin-walled automobile bumpers:

[0037] In parts by weight, 30 parts of modified special talcum powder prepared in step (1) and 60 parts of K9820H polypropylene with a flow rate of 17.5 g / min, 8 parts of elastomer, 0.1 part of DSTP168 antioxidant, other auxiliary agents : Lubricant white oil and 1.9 parts of vinyl bis stearamide are added to the mixer and mixed evenly, then added to the twin-screw extruder, melted, extruded, cooled, and pelletized by the twin-screw extruder Prepared as a polypropylene composite material for bumpers.

[0038] The processing temperatures in zones I to X of the twi...

Embodiment 2

[0040] (1) Preparation of modified special talcum powder:

[0041] According to parts by weight, add 98 parts of special talc powder with mesh number of 3000 mesh and diameter-to-thickness ratio of 30:1; 2 parts of silane dispersant, and mix them together in a high-speed kneader for 3 hours at a speed of 500 r / min .

[0042] (2) Preparation of a polypropylene composite material for thin-walled automobile bumpers:

[0043] In parts by weight, 70 parts of K9820H polypropylene, 8 parts of elastomer, 0.1 part of DSTP168 antioxidant, 20 parts of modified special talcum powder prepared in step (1) and 70 parts of K9820H polypropylene with a flow rate of 17.5 g / min, other additives : Lubricant white oil and 1.9 parts of vinyl bis stearamide are added to the mixer and mixed evenly, then added to the twin-screw extruder, melted, extruded, cooled, and pelletized by the twin-screw extruder Prepared as a polypropylene composite material for bumpers.

[0044] The processing temperatures...

Embodiment 3

[0046] (1) Preparation of modified special talcum powder:

[0047] According to parts by weight, add 98 parts of special talc powder with mesh number of 3000 mesh and diameter-to-thickness ratio of 30:1; 2 parts of silane dispersant, and mix them together in a high-speed kneader for 3 hours at a speed of 500 r / min .

[0048] (2) Preparation of a polypropylene composite material for thin-walled automobile bumpers:

[0049] In parts by weight, 80 parts of K9820H polypropylene, 8 parts of elastomer, 0.1 part of DSTP168 antioxidant, 10 parts of modified special talcum powder prepared in step (1) and 80 parts of K9820H polypropylene with a flow rate of 17.5 g / min, and other additives : Lubricant white oil and 1.9 parts of vinyl bis stearamide are added to the mixer and mixed evenly, then added to the twin-screw extruder, melted, extruded, cooled, and pelletized by the twin-screw extruder Prepared as a polypropylene composite material for bumpers.

[0050] The processing temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com