Composite solid-state polymer electrolyte and all-solid-state lithium battery

A technology of solid polymers and electrolytes, applied in solid electrolytes, non-aqueous electrolytes, secondary batteries, etc., can solve the problems of few correlation reports, achieve low raw material cost, simple preparation process, obvious cycle stability and high Effect of rate charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

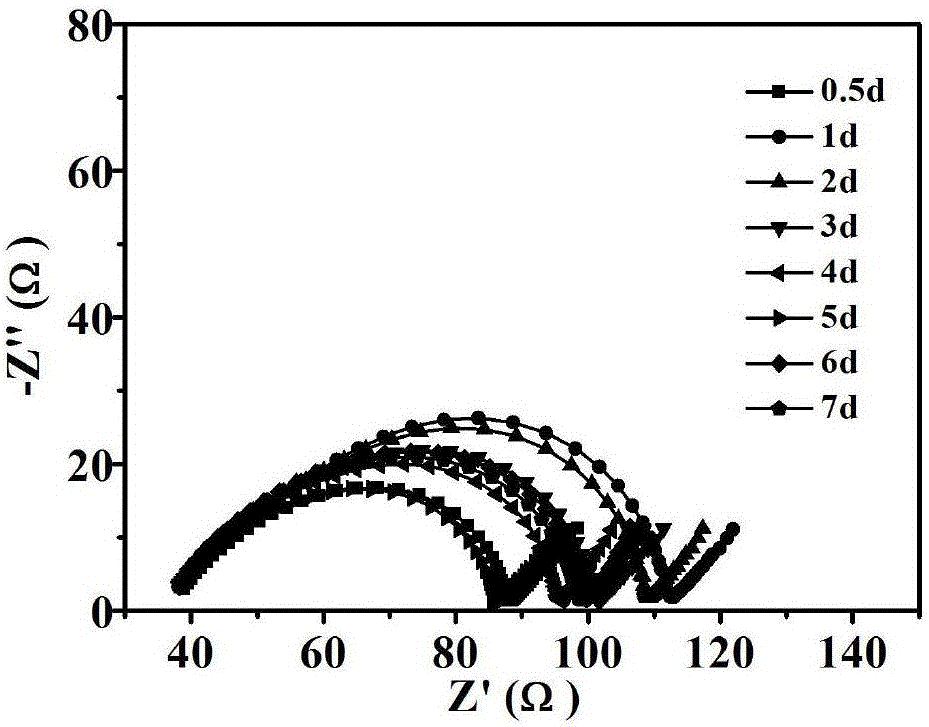

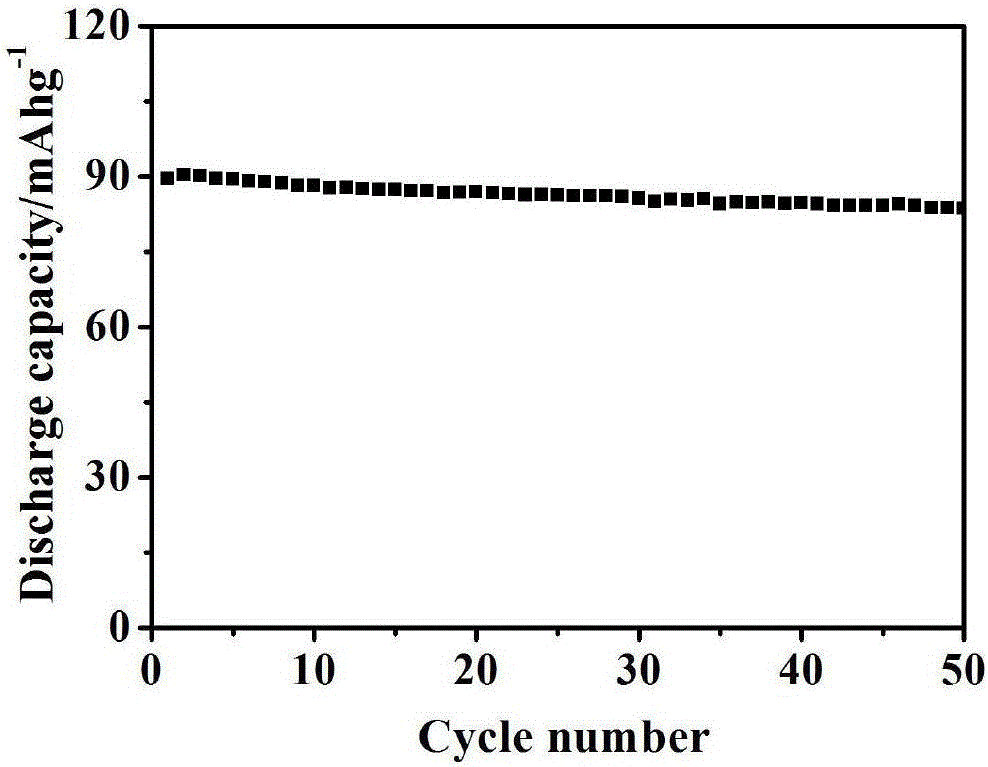

[0029]Composite solid polymer electrolytes were prepared by melting hot pressing method. First, polyacrylonitrile (PAN), CB[5] and lithium salt LiTFSI were thoroughly mixed at a mass ratio of 5:4:4 in an argon glove box, then placed in a vacuum oven at 80 °C for 12 h, and then transferred to In a polytetrafluoroethylene mold, hold the pressure at 65°C and 10MPa pressure for 2h to obtain a composite solid polymer electrolyte with a thickness of 50μm. The surface morphology of the electrolyte membrane was observed by scanning electron microscopy (SEM). The surface of the electrolyte membrane was smooth and even, and the particles were uniformly dispersed. The electrochemical window of the prepared electrolyte film was 4.8V; the Li / / Li symmetric battery was assembled, and the interface impedance of the symmetric battery was measured at 60°C at different times, and the interface impedance stabilized at 66Ω after 7 days. Using LiCoO 2 Assemble an all-solid lithium battery, the ba...

Embodiment 2

[0031] The composite solid polymer electrolyte was prepared by solution casting method. Firstly, polyethylene dithiol, CB[6] and lithium salt LiFSI with a mass ratio of 8:4:1 were fully dissolved in acetonitrile in an argon glove box, stirred for 12 hours to obtain a uniform viscous solution, and then the solution Cast into a polytetrafluoroethylene mold, dry at room temperature for 48 hours, and vacuum dry at 30°C for 48 hours to remove residual solvents to obtain a composite solid polymer electrolyte with a thickness of 60 μm. The surface morphology of the electrolyte membrane was observed by scanning electron microscopy (SEM). The surface of the electrolyte membrane was smooth and even, and the particles were uniformly dispersed. The electrochemical window of the prepared electrolyte film was 4.6V; a symmetrical Li / / Li symmetrical battery was assembled, and the interface impedance of the symmetrical battery at different times was measured at 60°C, and the interface impedanc...

Embodiment 3

[0033] Composite solid polymer electrolytes were prepared by melting hot pressing method. First, polyethylene oxide (PEO), CB[7] and lithium salt LiClO were mixed in an argon glove box 4 After fully mixing according to the mass ratio of 5:4:8, place it in a vacuum drying oven at 90°C for 5h, then transfer it to a polytetrafluoroethylene mold, hold the pressure at 80°C and 5MPa pressure for 15min, and obtain a composite solid state with a thickness of 70μm. polymer electrolyte. The surface morphology of the electrolyte membrane was observed by scanning electron microscopy (SEM). The surface of the electrolyte membrane was smooth and even, and the particles were uniformly dispersed. The electrochemical window of the prepared electrolyte film was 4.5V; a lithium-nickel alloy symmetric battery was assembled, and the interface impedance of the symmetric battery was measured at 60°C at different times, and the interface impedance stabilized at 74Ω after 7 days. Using LiFePO 4 Ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com