Method for improving compactness of aluminum alloy micro-arc oxide coating

A technology of micro-arc oxidation and aluminum alloy, which is applied in anodic oxidation and other directions, can solve the problems of low density and high energy consumption of aluminum alloy micro-arc oxidation coating, and achieve the effect of wide application range, good repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

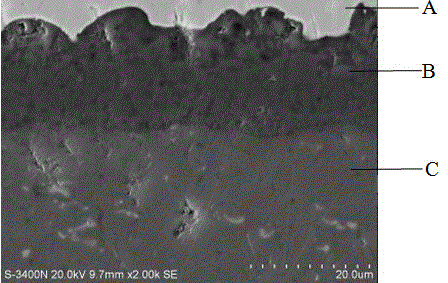

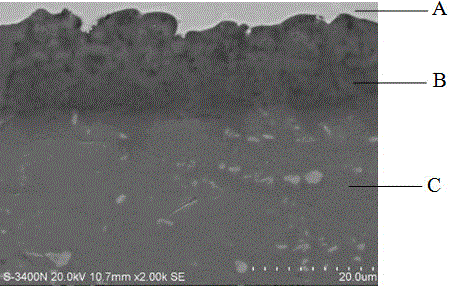

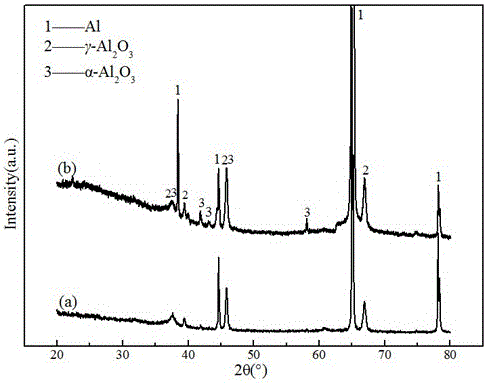

Image

Examples

Embodiment 1

[0023] A method for improving the compactness of an aluminum alloy micro-arc oxidation coating, comprising the following steps:

[0024] 1. Sample pretreatment: the aluminum alloy sample is polished to smooth step by step with sandpaper, then ultrasonically cleaned in acetone for 15 minutes, and air-dried at room temperature;

[0025] 2. Coating preparation: the aluminum alloy sample is used as the anode, the stainless steel tank is used as the cathode, the anode is immersed in the electrolyte, the AC constant voltage mode is used for micro-arc oxidation treatment, the electrical parameters are set, the treatment temperature is 35~45°C, the treatment Time 30min; wash off the remaining electrolyte on the surface of the sample with cold water, and air-dry at room temperature; the electrolyte is 12g / L sodium silicate, 1.5g / L potassium hydroxide, 2g / L sodium fluoride, 6ml / L triethanolamine, 2ml / L hydrogen peroxide; the electrical parameters are positive voltage 440V, negative vol...

Embodiment 2

[0028] A method for improving the compactness of an aluminum alloy micro-arc oxidation coating, comprising the following steps:

[0029] 1. Sample pretreatment: the aluminum alloy sample was polished step by step with sandpaper until smooth, then ultrasonically cleaned in acetone for 5 minutes, and air-dried at room temperature;

[0030] 2. Coating preparation: the aluminum alloy sample is used as the anode, the stainless steel tank is used as the cathode, the anode is immersed in the electrolyte, and the AC constant voltage mode is used for micro-arc oxidation treatment, the treatment temperature is 25~40°C, and the treatment time is 30min; Wash off the remaining electrolyte on the surface of the sample with cold water, and air-dry at room temperature; the electrolyte is 20 g / L sodium metaaluminate, 0.5 g / L sodium hydroxide, 0.5 g / L ethylenediaminetetraacetic acid, 1 g / L sodium pyrophosphate ;The electrical parameters are positive voltage 420V, negative voltage 125V, positive...

Embodiment 3

[0034] A method for improving the compactness of an aluminum alloy micro-arc oxidation coating, comprising the following steps:

[0035] 1. Sample pretreatment: the aluminum alloy sample was polished to smooth step by step with sandpaper, then ultrasonically cleaned in acetone for 10 minutes, and air-dried at room temperature;

[0036]2. Coating preparation: the aluminum alloy sample is used as the anode, the stainless steel tank is used as the cathode, the anode is immersed in the electrolyte, and the AC constant voltage mode is used for micro-arc oxidation treatment. 30min; wash off the residual electrolyte on the surface of the sample with cold water, and air-dry at room temperature; the electrolyte is 5g / L sodium phosphate, 4 g / L potassium hydroxide, 10ml / L triethanolamine; the electrical parameters are positive voltage 480V, negative voltage It is 0V, the positive duty cycle is 8%, the negative duty cycle is 0%, and the frequency is 700Hz;

[0037] 3. Laser treatment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com