Preparing method for composite coating integrating photocatalysis and protection performance of magnesium alloy surface

A technology of composite coating and magnesium alloy, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems of limited protection performance and low electrode potential, so as to improve the protection performance and reduce the manufacturing cost , Excellent photocatalytic performance and the effect of anti-corrosion and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

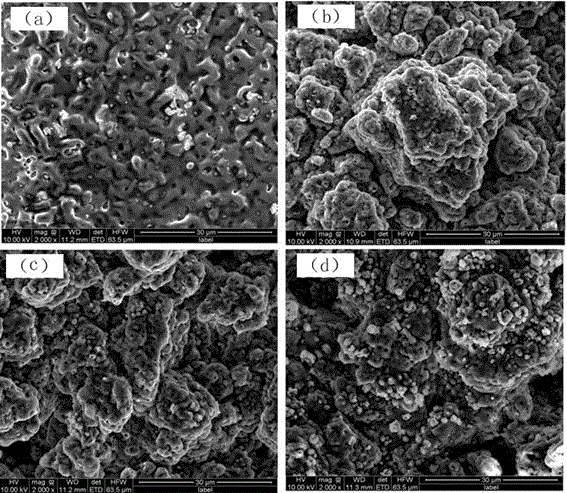

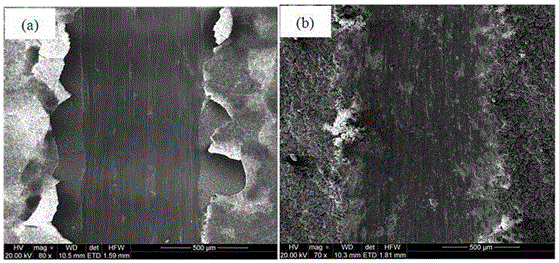

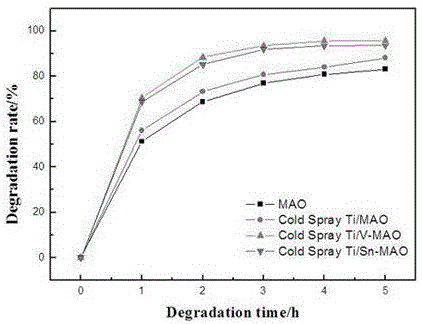

[0028] In this embodiment, the composite coating on the surface of the magnesium alloy is a cold-sprayed Ti / MAO composite coating, that is, a Ti transition layer is first prepared on the surface of the magnesium alloy substrate and then subjected to micro-arc oxidation. The transition layer utilizes cold spray technology to make the magnesium alloy A Ti overcoating layer with uneven surface characteristics is formed on the surface of the substrate, and the thickness of the transition layer is about 200 µm, and the thickness of the MAO layer formed on the surface is about 10 µm.

[0029] The preparation method of the above-mentioned magnesium alloy surface composite coating comprises the following steps:

[0030] Step 1: The magnesium alloy substrate is mechanically polished, and the Ti coating is prepared by cold spraying process. The particle diameter of the Ti powder used is 6 µm, and nitrogen is the main powder feeding gas. The nitrogen is industrial-grade pure nitrogen, hea...

Embodiment 2

[0036] In this embodiment, the composite coating on the surface of the magnesium alloy is a cold sprayed Ti / V-MAO composite coating, that is, a Ti transition layer is prepared on the surface of the magnesium alloy substrate and then subjected to micro-arc oxidation. The transition layer utilizes cold spray technology to make A Ti overcoating layer with uneven surface characteristics is formed on the surface of the magnesium alloy substrate, and the thickness of the transition layer is about 150 µm. By preparing the micro-arc oxidation electrolyte, a V-doped MAO layer is formed on the surface with a thickness of about 15 µm.

[0037] The preparation method of the above-mentioned magnesium alloy surface composite coating comprises the following steps:

[0038] Step 1: The magnesium alloy substrate is mechanically polished, and the Ti coating is prepared by a cold spraying process. The particle diameter of the Ti powder used is 6 µm, and nitrogen is the main powder feeding gas. Th...

Embodiment 3

[0044] In this embodiment, the composite coating on the surface of the magnesium alloy is a cold sprayed Ti / Sn-MAO composite coating, that is, a Ti transition layer is prepared on the surface of the magnesium alloy substrate and then subjected to micro-arc oxidation. The transition layer utilizes cold spray technology to make A Ti overcoating layer with uneven surface characteristics is formed on the surface of the magnesium alloy substrate, and the thickness of the transition layer is about 250 µm. By preparing the micro-arc oxidation electrolyte, a Sn-doped MAO layer is formed on the surface with a thickness of about 20 µm. .

[0045] The preparation method of the above-mentioned magnesium alloy surface composite coating comprises the following steps:

[0046] Step 1: The magnesium alloy substrate is mechanically polished, and the Ti coating is prepared by cold spraying process. The particle diameter of the Ti powder used is 6 µm, and nitrogen is the main powder feeding gas....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com