Production method of red dragon fruit vinegar

The technology of a kind of red pitaya fruit and production method is applied in the field of production of red pitaya fruit vinegar, which can solve the problems of restricting the development of pitaya plantation, less large-scale industrial production, and unsatisfactory storage effect, so as to ensure food safety and shorten the production time. The production cycle and the effect of improving the conversion rate of ethanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of production method of red pitaya fruit vinegar, comprises the steps:

[0029] (1) Raw materials: choose ripe red dragon fruit with a sugar content of 13±1°B from the date of pollination of the dragon fruit within 33±2 days X , the color is bright red, the flesh is plump, juicy and fragrant, no disease spots, no rot;

[0030] (2) Beating: use DJ2-4.0 8KW double-channel beater for beating, adjust the feeding speed to 2500-3000kg / h, control the moisture content of slag seeds at the slag discharge port, and ensure that the juice yield is within the range of 50±5%;

[0031] (3) Juice viscosity adjustment: adjust and control the viscosity value of dragon fruit juice within the range of 120-125mpa.s, add 15±1% purified water to dilute and stir evenly;

[0032] (4) Enzymolysis: Add pectinase (enzyme activity: 30,000 U / g) according to 0.5% of the juice volume, stir evenly, stir and enzymolyze at 50±1°C for 2.5±0.5h;

[0033] (5) Sugar content adjustment: after the jui...

Embodiment 2

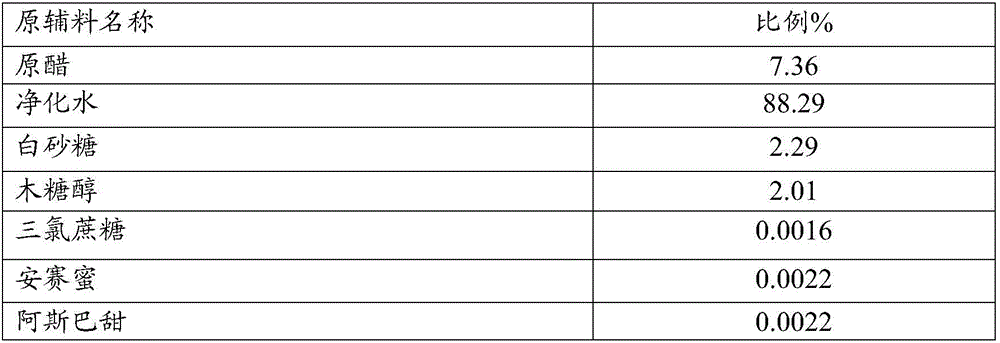

[0056] A kind of production method of red pitaya fruit vinegar drink, comprises the steps:

[0057] (1) Raw materials: select ripe red pitaya fruits that are 31±2 days from the date of pollination, and the sugar content should reach 12±1°B X , the color is bright red, the flesh is plump, juicy and fragrant, no disease spots, no rot;

[0058] (2) Beating: use DJ2-4.0 8KW double-channel beater for beating, adjust the feeding speed to 2500-3000kg / h, control the moisture content of slag seeds at the slag discharge port, and ensure that the juice yield is within the range of 50±5%;

[0059] (3) Juice viscosity adjustment: Use a viscometer to measure the juice viscosity value. Adjust and control the viscosity value of dragon fruit juice in the range of 120-140mpa.s, add 14±1% purified water to dilute and stir evenly;

[0060] (4) Enzymolysis: Add pectinase (enzyme activity: 30,000 U / g) according to 0.5% of the juice volume, stir evenly, stir and enzymolyze at 50±1°C for 2.5±0.5h; ...

Embodiment 3

[0087] A kind of production method that red pitaya fruit vinegar is cool, comprises the steps:

[0088] (1) Raw material: select ripe red dragon fruit with a sugar content of 14±1°B from the date of pollination of the dragon fruit within 35±2 days X , the color is bright red, the flesh is plump, juicy and fragrant, no disease spots, no rot;

[0089] (2) Beating: use DJ2-4.0 8KW double-channel beater for beating, adjust the feeding speed to 2500-3000kg / h, control the moisture content of slag seeds at the slag discharge port, and ensure that the juice yield is within the range of 50±5%;

[0090] (3) Juice viscosity adjustment: Use a viscometer to measure the juice viscosity value. Adjust and control the viscosity value of dragon fruit juice in the range of 120-140mpa.s, add 13±1% purified water to dilute and stir evenly;

[0091] (4) Enzymolysis: Add pectinase (enzyme activity: 30,000 U / g) according to 0.4% of the juice volume, stir evenly, stir at 50±1°C for 2.5±0.5h;

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com