Automatic milky tea maker

A milk tea machine, automatic technology, applied in beverage preparation devices, household utensils, applications, etc., can solve the problem of no unmanned milk tea machine, achieve low cost, reduce volume, and prevent odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

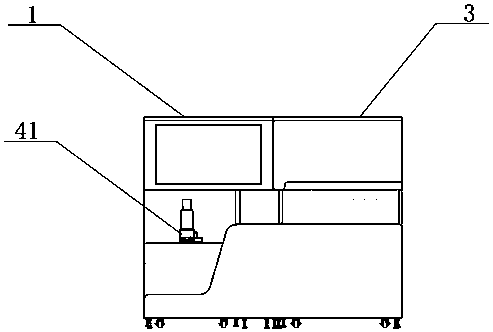

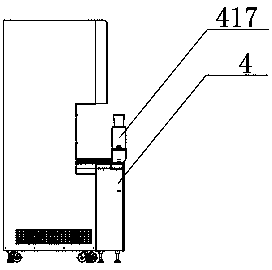

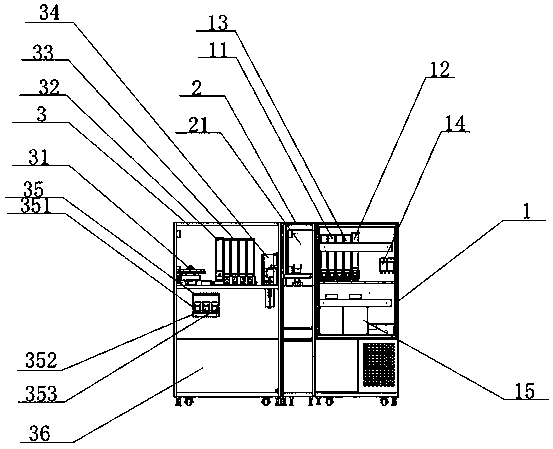

[0038] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

[0039] like Figure 1-3As shown, an automatic milk tea machine includes a low-temperature fresh-keeping box 1, an ice-making machine box 2, and a normal temperature box 3 that are cooperatively arranged from left to right. There is a rail box 4, and the upper part of the low-temperature fresh-keeping box 1 is equipped with a sauce output device 11, a large fruit output device 12, a cover material output device 13 and a juice pump 14, and the temperature of the low-temperature fresh-keeping box 1 is controlled at 4-5. ℃, the middle part of the low-temperature fresh-keeping box 1 is provided with the fruit juice barrel 15 with the juice pump 14, the said ice maker box 2 is provided with a fully automatic ice maker 21, and the upper part of the normal temperature box 3 is equipped with a cup dropper 31. Fructos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com