A kind of synthetic method of oil mist suppressing smoke lubricating ester and its application in cold heading oil and expanding oil

A synthesis method and technology of lubricating ester, which is applied in the field of synthesis of oil mist and smoke suppressing lubricating ester, can solve the problems of people getting lost and unable to escape, threatening the safety of life and property, and fast moving speed of smoke, etc. Effects of post-treatment and smoke reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

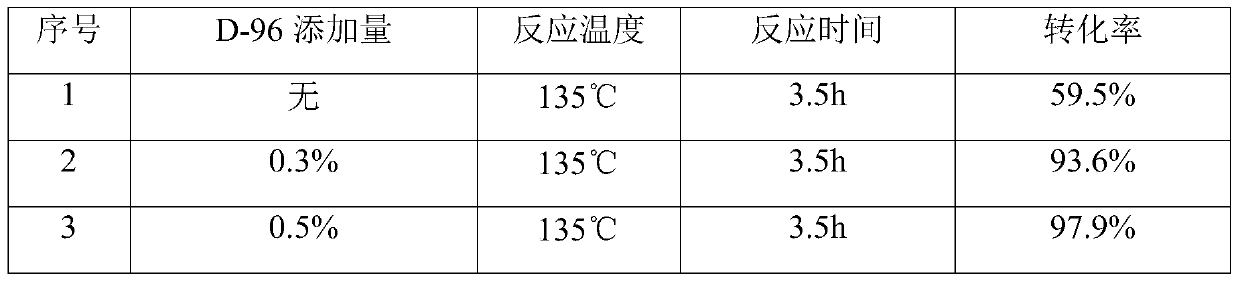

[0015] In order to investigate the influence of different catalysts on toluenesulfonic acid and ionic liquid catalyst D-96 on the reaction conversion rate, under the same conditions of raw material quality, reaction temperature, reaction time and molar ratio, the reaction conversion rate was compared, as follows:

[0016] First, add boric acid and glycerin into the reactor at a molar ratio of 1:2, and react at 130°C for 4 hours to obtain light yellow boric acid diglyceride; then add boric acid diglyceride and oleic acid into the reactor at a molar ratio of 1:1 , and then add the catalyst, vacuumize, rise to the set temperature and react for 3.5 hours, and the oil mist and smoke suppressing lubricating ester can be obtained.

[0017] At the same time, according to the same reaction conditions as above, the influence of different ionic liquid catalyst D-96 additions on the reaction conversion rate was compared.

[0018] The experimental results are shown in Table 1 and Table 2, ...

Embodiment 2

[0028] This embodiment synthesizes the oil mist smoke suppressing lubricating ester according to the following steps:

[0029] Weigh 62g of boric acid and 184g of glycerin into a three-necked flat-bottomed flask, heat up to 130°C, react for 4 hours, condense to remove 36g of by-product water, and obtain 210g of boric acid diglyceride; add 282g of oleic acid and 2.46g of catalyst to boric acid diglyceride D-96, evacuate to P=-0.06MP, raise the temperature to 135°C, and react for 3.5 hours to obtain oil mist suppressing smoke lubricating ester with an acid value of 0.8mgKOH / g.

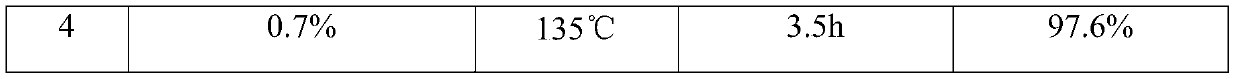

[0030] Carry out the following lubricity experiments on the oil mist suppressing smoke lubricating ester obtained in this example, and compare it with other several esters (chlorinated paraffin s-52, triisopropylphenyl phosphate IPPP, vulcanized lard) at the same time:

[0031] Wear test: The model of the four-ball machine used is MS-10J (made in Xiamen), the speed is 1200r / min, the diameter of the steel...

Embodiment 3

[0043] This embodiment synthesizes the oil mist smoke suppressing lubricating ester according to the following steps:

[0044] Weigh 62g of boric acid and 184g of glycerol into a three-necked flat-bottomed flask, heat up to 130°C, react for 4 hours, condense to remove 36g of by-product water, and obtain 210g of boric acid diglyceride; add 450g of heavy alkylbenzenesulfonic acid and 3. 30g of catalyst D-96, evacuated to P=-0.04MP, heated up to 135°C, and reacted for 3.5h to obtain oil mist suppressing smoke lubricating ester with an acid value of 0.6mgKOH / g.

[0045] Carry out the following lubricity experiments on the oil mist suppressing smoke lubricating ester obtained in this example, and compare it with other several esters (chlorinated paraffin s-52, triisopropylphenyl phosphate IPPP, vulcanized lard) at the same time:

[0046] Wear test: The model of the four-ball machine used is MS-10J (made in Xiamen), the speed is 1200r / min, the diameter of the steel ball is Φ12.7, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com