Hydrodesulfurization method of catalytic cracking gasoline

A technology for catalytic cracking gasoline and hydrodesulfurization, which is applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, catalysts for physical/chemical processes, etc., and can solve the problems of complex structure and long reaction time of layered composite hydroxides. , to achieve long-term stable operation, low octane loss, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

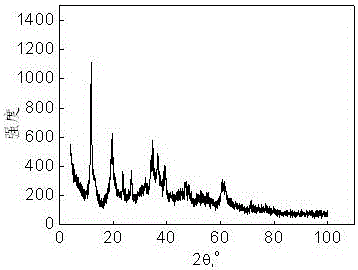

Image

Examples

Embodiment 1

[0030] Dissolve 1.2kg of zinc nitrate in 6L of water to make a solution containing zinc, and dissolve 0.24kg of sodium metaaluminate and 0.30kg of sodium carbonate in 4L of water to make a solution containing aluminum. Divide the zinc-containing solution into 3 equal parts, each 2L. Take 2L of zinc-containing solution, keep the temperature at 80°C, add aluminum-containing mixed solution dropwise to it until the pH value reaches 9.0; stop dropping the aluminum-containing mixed solution, then add 2L of zinc-containing solution dropwise to the mixing system, and continue to drop aluminum-containing solution Mix the solution until the pH value reaches 9.0; titrate the aluminum-containing mixed solution and the zinc-containing solution alternately until all the zinc-containing solutions are added, and add the aluminum-containing mixed solution dropwise until the pH reaches 9.0. The total titration time is 3 hours. The obtained mixture was aged at 80°C for 4h, cooled and washed unti...

Embodiment 2

[0041] The preparation method and steps of the zinc oxide-alumina composite carrier containing additives are the same as in Example 1, and the zinc oxide containing zinc aluminum spinel is prepared, and the pH value is adjusted to 8.7. In terms of oxides, the content of zinc oxide is 70%; the specific surface area is 191m 2 / g. The difference is that after the composite carrier is obtained, potassium and strontium are used to modify the surface of the zinc oxide-alumina composite carrier containing additives. Potassium nitrate 3.0g, strontium nitrate 3.0g, completely dissolved in 30ml of distilled water, then diluted with deionized water, made into an impregnation solution impregnated with zinc oxide-alumina composite carrier, dried and roasted to obtain the surface with additives potassium and strontium Modified zinc oxide-alumina composite support. The specific surface area of the composite carrier is 233m 2 / g.

Embodiment 3

[0045] The preparation method and steps of the zinc oxide-alumina composite carrier containing additives are the same as in Example 1. Zinc oxide containing zinc aluminum spinel was prepared, and the pH value was adjusted to 9.3. Zinc oxide containing zinc aluminum spinel, calculated as oxide, the content of zinc oxide is 63%; the specific surface area is 214m 2 / g.

[0046] The composite support includes 17wt% zinc oxide containing zinc-aluminum spinel, the content of alumina is 80 wt%, and the contents of boron, potassium and strontium in the additive components are B 2 o 3 1.2 wt%, K 2 O 0.9 wt%, SrO 0.9 wt%. Composite carrier specific surface area 259m 2 / g.

[0047] Ammonium molybdate and cobalt nitrate were made into an impregnation solution, and ammonia water was added to adjust the pH value so that the salt was completely dissolved, and then the zinc oxide-alumina composite carrier surface-modified with auxiliary agents potassium and strontium was impregnated. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com