Graphene/polyether ether ketone composite powder material and preparation method for sls

A technology of polyether ether ketone and composite powder, which is applied in the direction of additive processing, etc., can solve the problems of poor fluidity, uneven shape, and low bonding strength, and achieve good fluidity, uniform shape, and good sphericity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

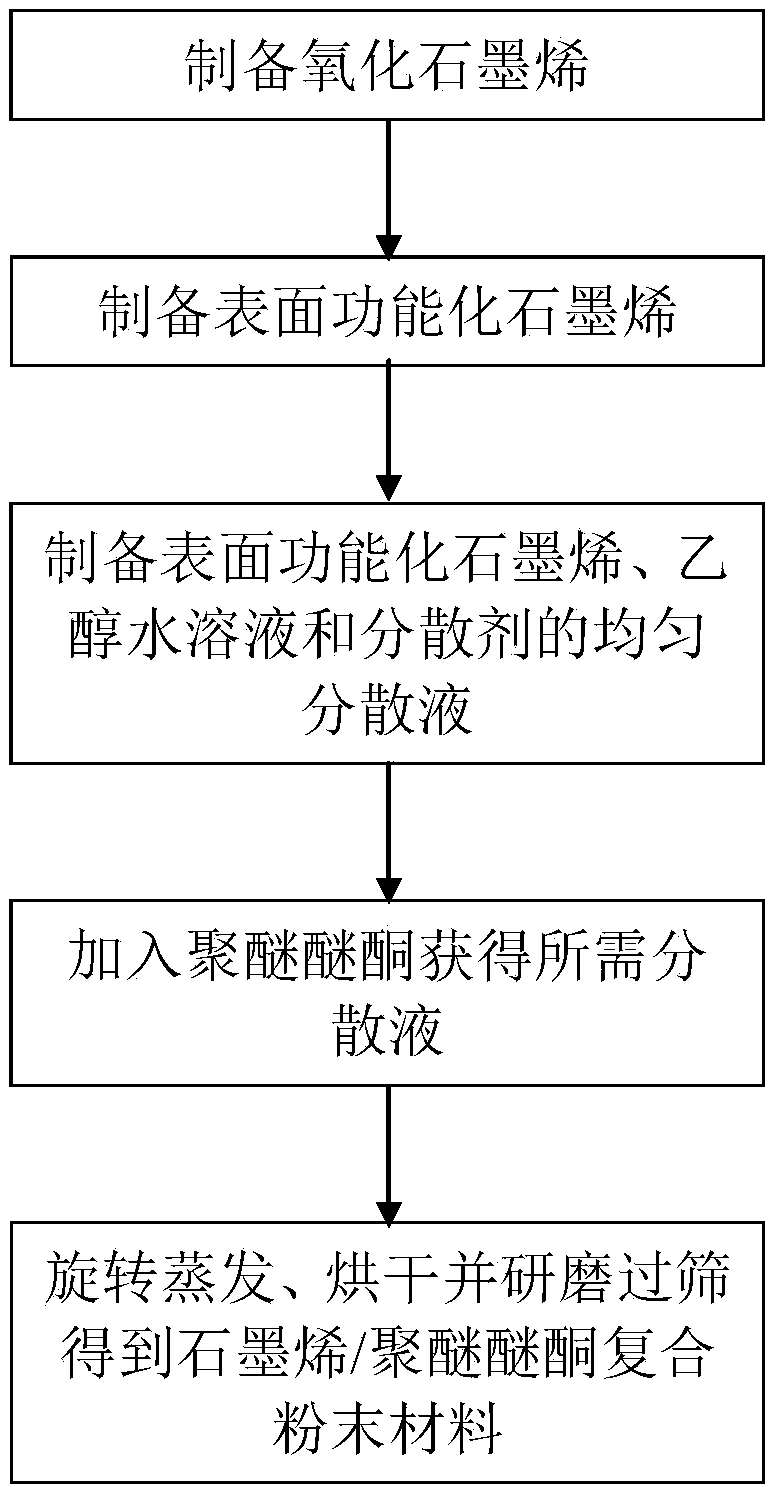

[0030] The preparation method of the graphene / polyether ether ketone composite powder material used in the SLS technology provided by the present invention adopts the method of blending and evaporating in solution, and specifically includes the following steps:

[0031](1) Add graphene to concentrated sulfuric acid solution at 0°C, ultrasonicate at 240W 50Hz for 10min, stir at 400-500r / min for 10min, circulate like this for 2h, then slowly add potassium permanganate at a rate of 1g / min to dissolve it , heat up to 30-40°C and keep for 15-25h, after the reaction, transfer the solution to distilled water at 85-95°C and keep for 30min, cool to room temperature, add 30% hydrogen peroxide solution, settle, pour off the upper clear night, 8000-9000r / min high-speed centrifugation for 5 minutes, take out the upper clear layer with a dropper, and repeat the centrifugation three times. The obtained product is washed with 5% dilute hydrochloric acid solution to remove residual sulfate ion...

Embodiment 1~2

[0045] (1) Add 3g of graphene to 120ml of concentrated sulfuric acid solution at 0°C, ultrasonicate at 240W 50Hz for 10min, stir at 400r / min for 10min, and circulate like this for 2h, then slowly add 18g of potassium permanganate at a rate of 1g / min to make it Dissolve and heat up to 40°C for 15h. After the reaction, transfer the solution to 400ml of distilled water at 85°C for 30min, cool to room temperature, add 15ml of 30% hydrogen peroxide solution, settle, pour off the supernatant, centrifuge at 8000r / min for 5min, take out the supernatant with a dropper, The centrifugation was repeated three times, and the obtained product was washed with 5% hydrochloric acid solution to remove residual sulfate ions, washed with distilled water to neutrality, and treated in a vacuum oven at 60°C for 24 hours to constant weight to obtain GO.

[0046] (2) Disperse 0.3g GO evenly in 1L 10vol% ethanol aqueous solution, sonicate at 240W 50Hz for 10min, stir at 400r / min for 10min, and circulat...

Embodiment 3~4

[0051] (1) Add 3g of graphene to 120ml of concentrated sulfuric acid solution at 0°C, ultrasonicate at 240W 50Hz for 10min, stir at 450r / min for 10min, circulate like this for 2h, then slowly add 18g of potassium permanganate at a rate of 1g / min to make it Dissolved and heated to 35°C for 20h. After the reaction, transfer the solution to 400ml of distilled water at 93°C for 30min, cool to room temperature, add 15ml of 30% hydrogen peroxide solution, settle, pour off the supernatant, centrifuge at 8500r / min for 5min, take out the supernatant with a dropper, repeat After centrifugation three times, the obtained product was washed with 5% hydrochloric acid solution to remove residual sulfate ions, washed with distilled water until neutral, and treated in a vacuum oven at 60°C for 24 hours to constant weight to obtain GO.

[0052] (2) Disperse 0.7g GO evenly in 1L 50vol% ethanol aqueous solution, sonicate at 240W 50Hz for 10min, stir at 450r / min for 10min, and circulate like this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com