Fluorine rubber material for high temperature and high pressure resistant seals and preparation method thereof

A technology of high-pressure sealing and fluororubber, which is applied in the field of fluororubber materials for high-temperature and high-pressure resistant seals and its preparation, and can solve the problems of high hardness, high tensile strength, high resistance to shear deformation, explosion-proof, and inability to tolerate complex media. and other problems, to achieve excellent anti-gas rapid pressure release performance, improve hardness, and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

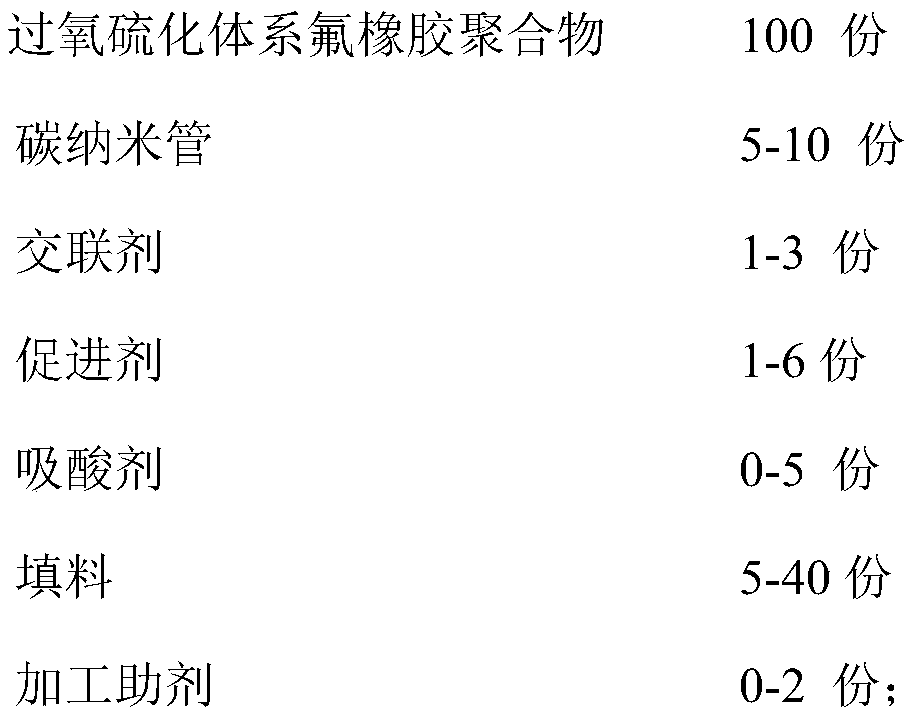

[0025] The formula of embodiment 1 peroxygen vulcanized fluorine rubber material

[0026] Table 1 shows the formulations of No. 1 to No. 4 peroxyvulcanized fluororubber materials. For detailed ratios, refer to the ratio of each component in the table.

[0027] Table 1 Formulas of No. 1 to No. 4 peroxyvulcanized fluororubber materials

[0028] serial number number 1 number 2 number 3 No 4 Viton GF 100.00 100.00 100.00 100.00 carbon nanotube GTR 0.00 5.00 10.00 15.00 Accelerator TAIC-S70 4.00 4.00 4.00 4.00 Cross-linking agent 101XL-45 1.50 1.50 1.50 1.50 Zinc oxide META-Z102 3.00 3.00 3.00 3.00 Carbon black N 990 30.00 25.00 20.00 15.00 Processing aid Struktol HT 290 1.00 1.00 1.00 1.00 total number of copies 139.50 139.50 139.50 139.50

Embodiment 2

[0029] The performance test of embodiment 2 peroxygen vulcanized fluorine rubber material

[0030] Weigh each component according to the ratio of No. 1 to No. 4 formulas (parts by weight) in Example 1, wrap the peroxysulfurized fluororubber on a double-roller rolling machine, and carbon nanotubes, crosslinking agents, accelerators, Auxiliary materials such as acid absorbing agent zinc oxide, carbon black and processing aids are added to the open mill and mixed with fluororubber, and the roller temperature is lower than 80°C, and the mixture is evenly mixed and flakes are produced to obtain fluororubber compound. The mixed rubber was molded and vulcanized into a standard rubber test piece under the condition of 10 minutes of one-stage vulcanization at a temperature of 180°C, and then second-stage vulcanization at a temperature of 200°C for 12 hours, and the rubber test piece was prepared according to a standard test sample and tested. Test, the performance parameters of No. 1-4...

Embodiment 3

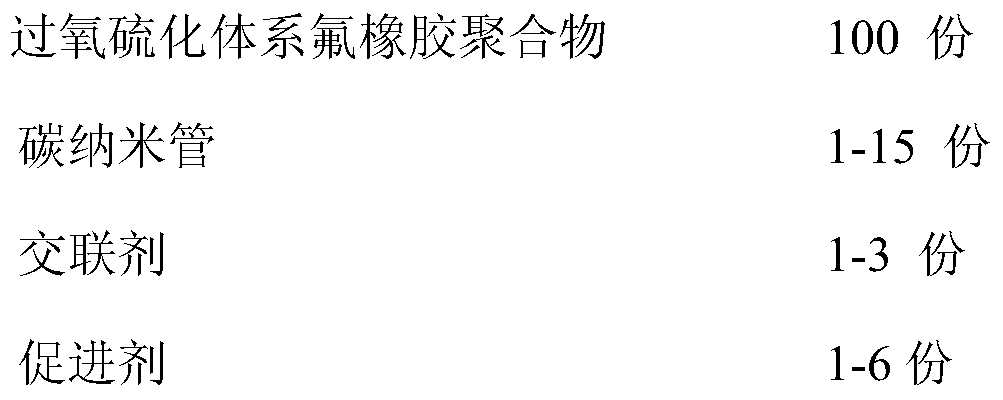

[0040] The formula of embodiment 3 peroxygen vulcanized fluororubber materials

[0041] Table 3 shows the formulations of No. 5 to No. 8 peroxyvulcanized fluororubber materials. For detailed ratios, refer to the ratio of each component in the table.

[0042] Table 3 Formulas of No. 5 to No. 8 peroxyvulcanized fluororubbers

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com