System and method for preparing ethylene through acetylene hydrogenation

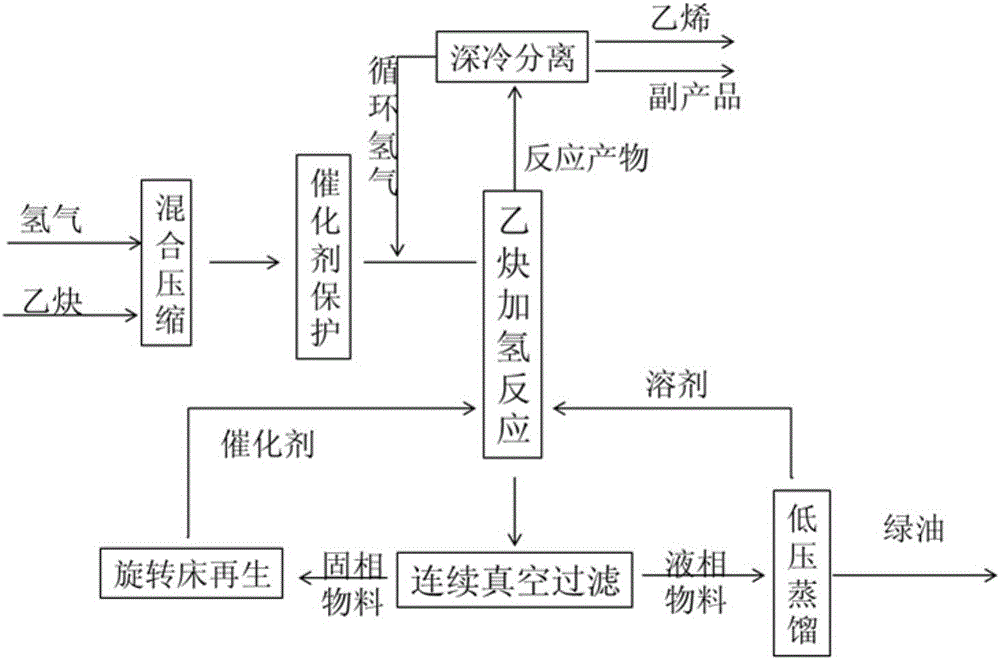

A technology for acetylene hydrogenation and ethylene production, which is applied in the system field of acetylene hydrogenation to ethylene, which can solve the problems of noble metal catalyst deactivation, low precision of acetylene purification process, and catalyst activity decline, so as to avoid green oil accumulation and reduce occupation Land and investment, the effect of state stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The invention provides a method for producing ethylene by hydrogenation of high-purity acetylene, the process of which is as follows:

[0101] Mix the catalyst diluent aluminum oxide with a particle size of 100 mesh to 150 mesh and the acetylene hydrogenation catalyst according to the mass ratio of 1:1, and then add it into the slurry bed and mix it with the solvent N-methyl pyrrolidone to form a slurry.

[0102] The reaction gas enters the slurry through the internal gas distributor of the slurry bed, the molar ratio of hydrogen to acetylene in the slurry bed is 5:1, and the reaction is carried out at 170°C. After the reaction, the gas phase material is subjected to cryogenic separation to obtain the target product ethylene, and the recovered hydrogen is mixed with the raw material hydrogen and returned to the hydrogenation reaction unit. The liquid phase material is passed through the rotary drum vacuum filter to obtain solid phase material and liquid phase material. ...

Embodiment 2

[0104] Using the system of the present invention, the process of hydrogenation of high-purity acetylene to ethylene of the present invention is:

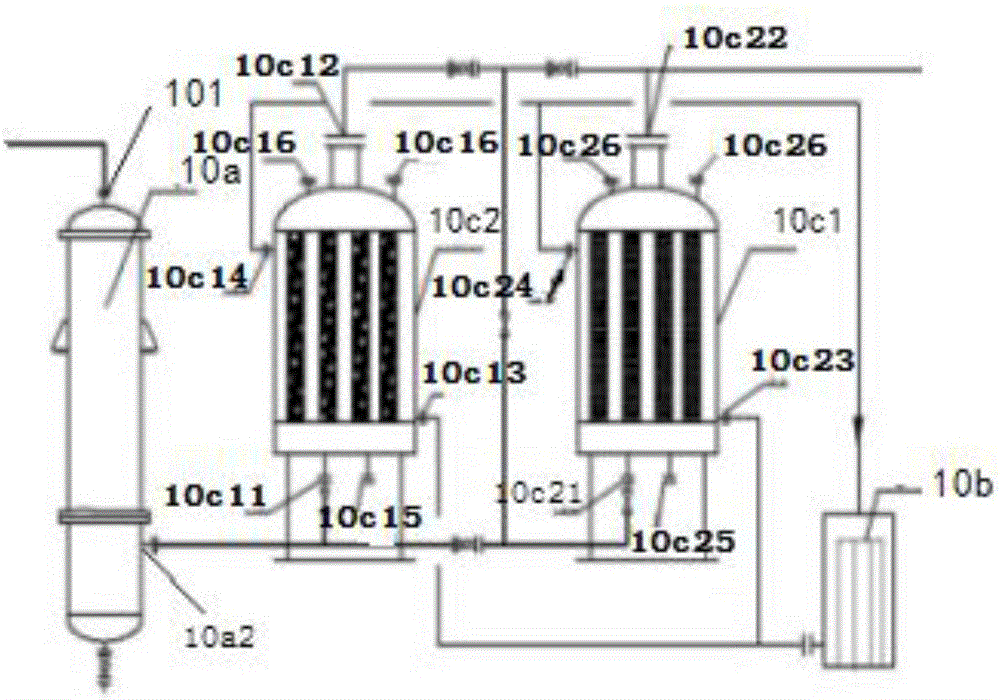

[0105] Mix the catalyst diluent aluminum oxide with a particle size of 100 mesh to 150 mesh and the acetylene hydrogenation catalyst according to the mass ratio of 2:1, and then add it into the slurry bed and mix it with the solvent N-methyl pyrrolidone to form a slurry. Acetylene and hydrogen are mixed and pressurized through a compressor at a molar ratio of 1:1 to form a mixed gas, and the pressure is raised to 0.18MPa, the temperature is 60°C, and the dew point is -44°C. The compressed raw gas enters the raw gas heat exchanger and cools down to 28°C, and passes through the tubular catalyst protector to obtain purified gas; the temperature of the protective agent bed is 28°C, and the active components of the protective agent are copper oxide and zinc oxide. For ceramics; space velocity 1500h -1 , Pressure drop 100KPa.

[0106] W...

Embodiment 3

[0109] The process for producing ethylene by hydrogenation of high-purity acetylene of the present invention is:

[0110] Mix the catalyst diluent perlite particles with a particle size of 100 mesh to 150 mesh and the acetylene hydrogenation catalyst in a mass ratio of 10:1 to form a solid phase material, and then add it to the slurry bed and mix it with the solvent N-methyl pyrrolidone to form a slurry . Acetylene and hydrogen are mixed with the pressure-lifting unit through the compressor at a molar ratio of 1:1 to form a mixed gas. After compression, the pressure of the raw material gas is 0.22MPa, the temperature is 70°C, and the dew point is -46°C. The compressed raw material gas enters the raw material The temperature of the gas heat exchanger is lowered to 30°C, and the purified gas is obtained through the tubular catalyst protector. The active components of the protector are silver oxide and zinc oxide, the carrier is spherical alumina, the bed temperature is 30°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com