Preparation method of ionic intercalation type two-dimensional material

A technology of two-dimensional materials and ions, which is applied in the field of preparation of ion-intercalated two-dimensional materials, can solve the problems of hindering commercial production, complicated preparation process, long reaction time, etc., and achieves low preparation cost and simple sample cleaning process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

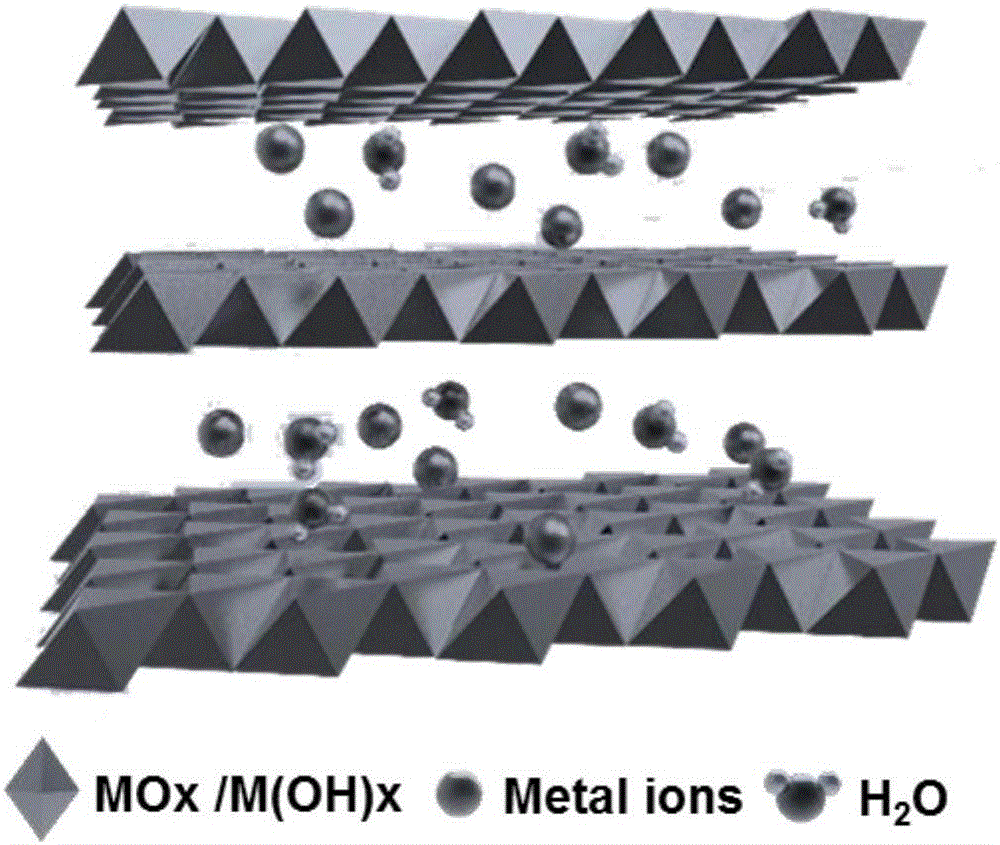

[0020] The preparation method of the ion intercalation type two-dimensional material provided in the example uses a salt with a low melting point as a molten salt and a metal salt as a precursor, reacts at a specific temperature for a certain period of time, and after cooling to room temperature, rinses and extracts the material with deionized water. Filtration, to obtain ion intercalation type two-dimensional material powder; specifically include the following steps:

[0021] (1) Put the salt with low melting point in the muffle furnace, and the furnace temperature is set between the melting point of the salt and its decomposition temperature or boiling point, so that the salt becomes molten; the types of molten salt include but are not limited to: nitrate, chlorination Salt, sulfate, phosphate;

[0022] (2) adding the metal salt precursor to the molten salt for reaction; wherein, the metal element types of the metal salt include but are not limited to: Al, Ca, Ti, V, Cr, Mn,...

Embodiment 1

[0028] (1) Add 5g NaNO 3 Place in a crucible, place the crucible in a muffle furnace, and heat at 350°C for ten minutes until NaNO 3 become molten

[0029] (2) 0.2g MnSO 4 The powder is quickly added to the above molten NaNO 3 , respond for 10 seconds;

[0030] (3) The product after the reaction is naturally lowered to room temperature, and is cleaned and suction-filtered with deionized water to remove the salt therein;

[0031] (4) Dry the cleaned sample at 80°C to obtain two-dimensional Na 0.55 mn 2 o 4 1.5H 2 O nanosheets.

Embodiment 2

[0033] (1) 5g KNO 3 Place in a crucible, place the crucible in a muffle furnace, and heat at 380°C for ten minutes to KNO 3 become molten

[0034] (2) 0.2g MnSO 4 The powder is quickly added to the above molten KNO 3 , react for one minute;

[0035] (3) The product after the reaction is naturally lowered to room temperature, and is cleaned and suction-filtered with deionized water to remove the salt therein;

[0036] (4) Dry the cleaned sample at 80°C to obtain a two-dimensional K 0.27 MnO 2 0.54H 2 O nanosheets.

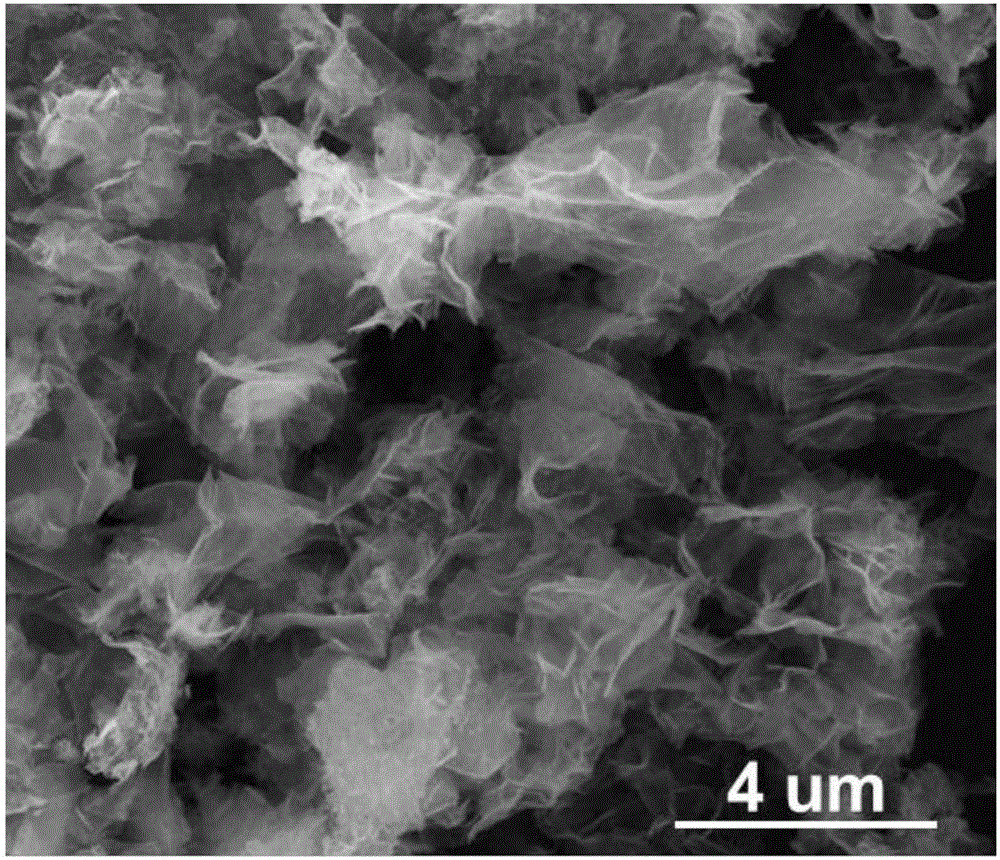

[0037] The two-dimensional cation intercalation type metal oxide material K prepared in Example 2 0.27 MnO 2 0.54H 2 SEM images of O nanosheets as figure 2 As shown, it can be seen from the figure that the prepared two-dimensional material has a uniform morphology and no other morphology such as nanoparticles.

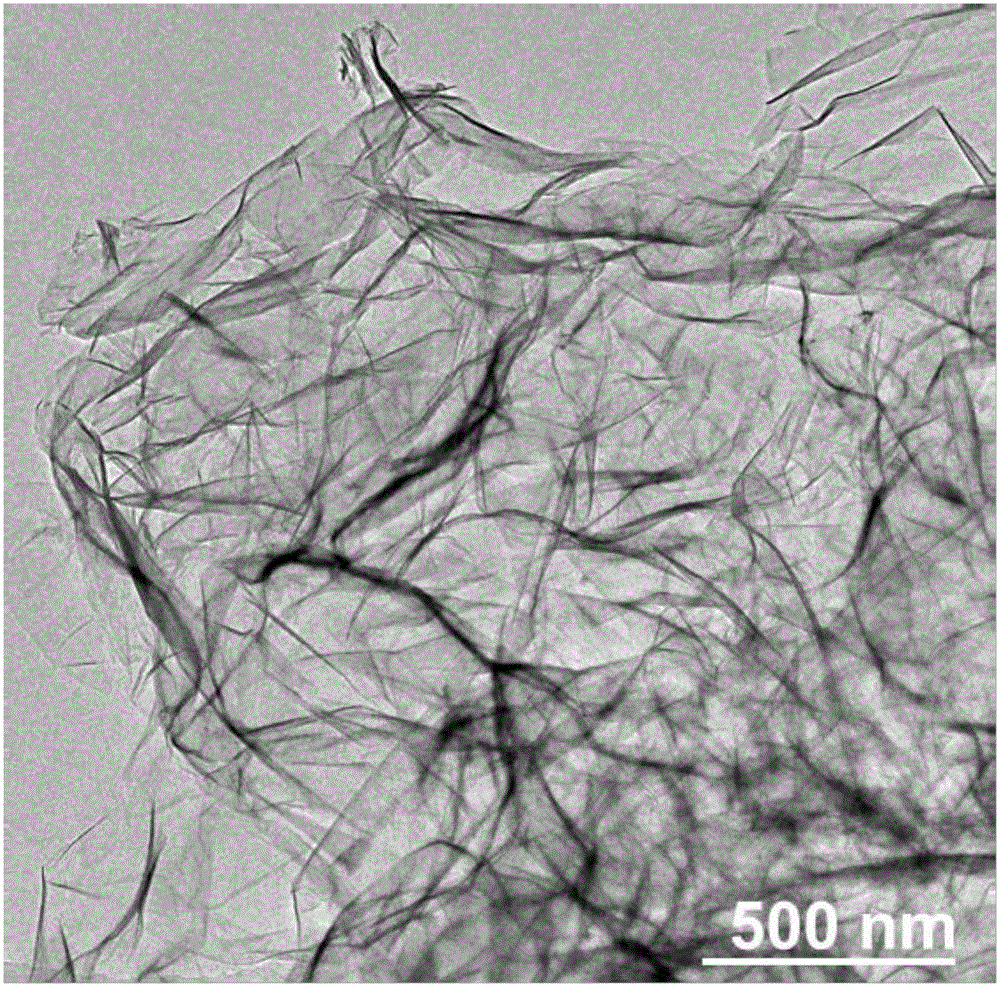

[0038] Such as image 3 Shown is the two-dimensional cation intercalation type metal oxide material K prepared in Example 2 0.27 MnO 2 0.54H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com