Quick 3D printing device and quick printing method

A 3D printing and fast technology, applied in 3D object support structure, additive manufacturing, processing platform/substrate, etc., can solve the problems of slow printing speed and affecting printing efficiency, and achieve the effect of improving printing speed and high-precision printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

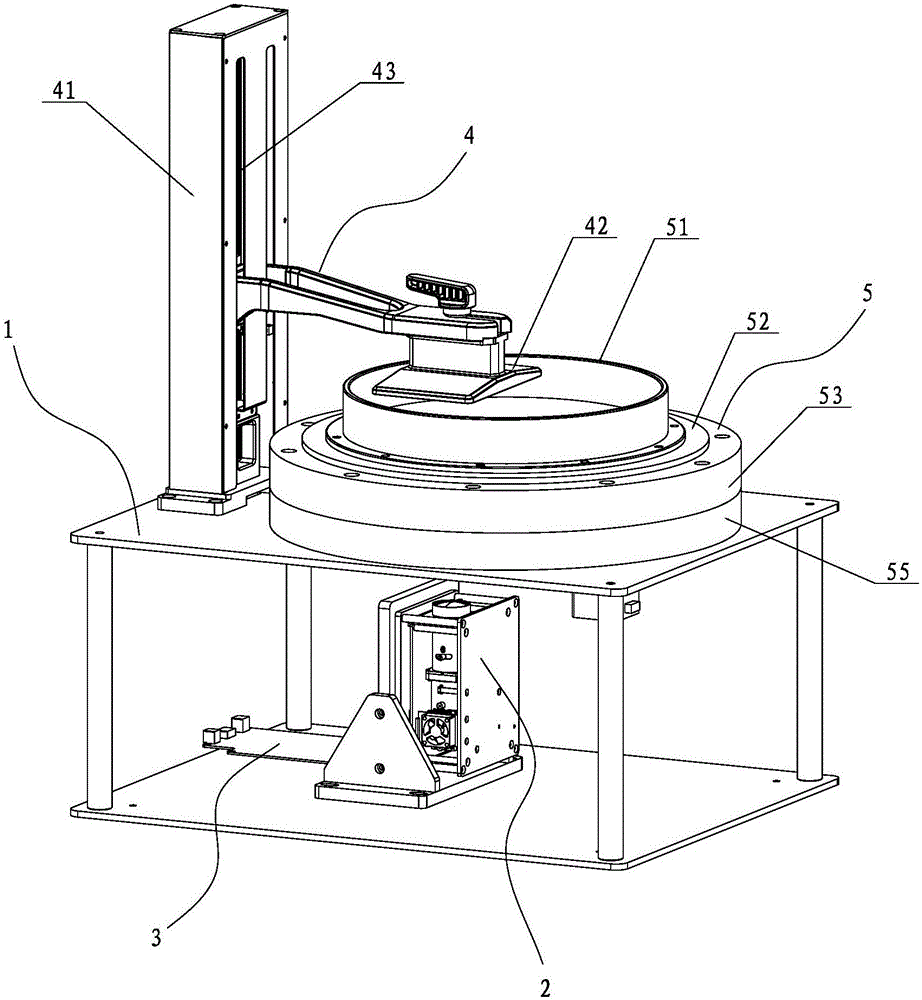

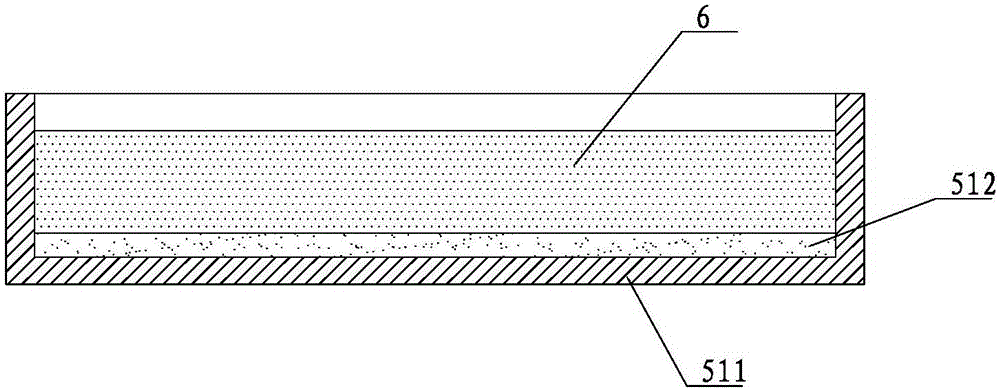

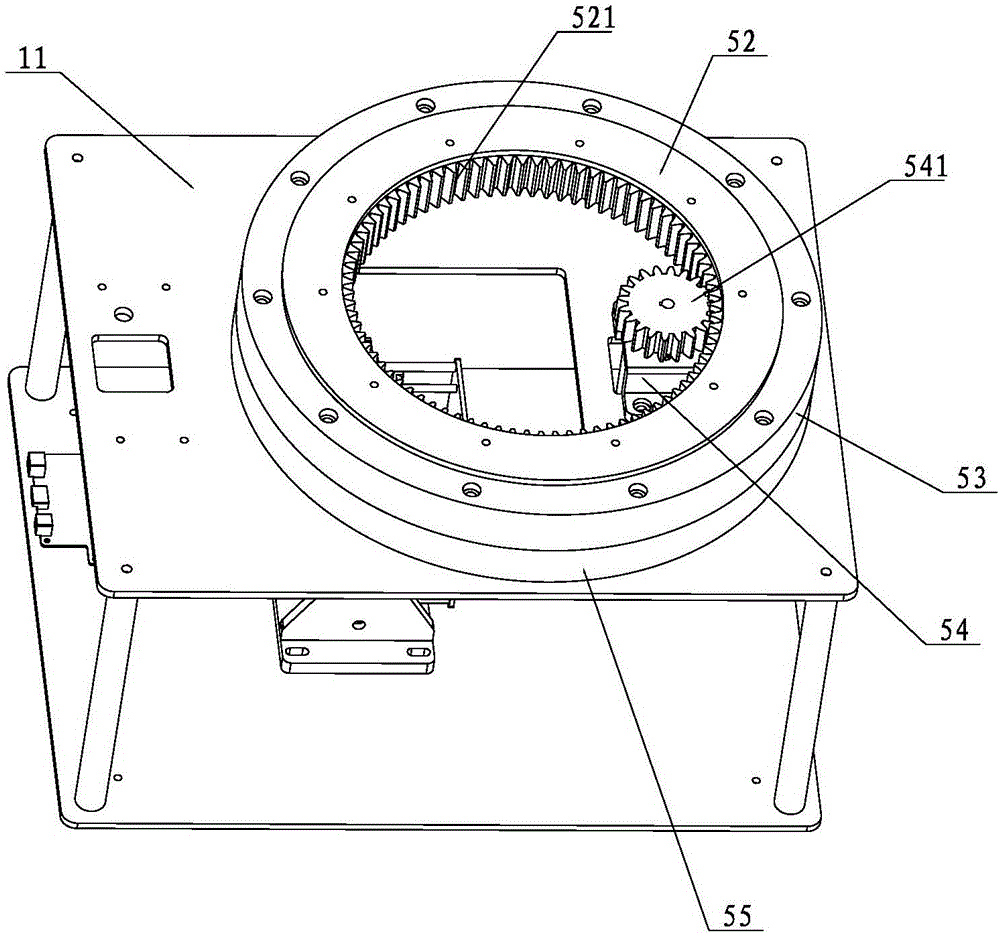

[0031] Such as figure 1 As shown, a rapid 3D printing device includes a base 1, an exposure mechanism 2 arranged in the base 1, a control mechanism 3, a printing mechanism 4 and a liquid holding mechanism 5 arranged on the base 1, wherein the The printing mechanism 4 includes a module 41 and a printing platform 42 slidably installed on the module 41. In this embodiment, the printing platform 42 slides up and down through a screw 43 vertically arranged on the module 41. The printing platform 42 is connected with the lead screw 43, and the lead screw 43 is connected with the lead screw motor. The lead screw 43 is driven to rotate by the lead screw motor, and then drives the printing platform 42 to move. During the printing process, the printing platform can rise at a constant speed. The control mechanism 3 is controlled by a microprocessor, and the control mechanism is respectively connected with the exposure mechanism 2, the printing mechanism 3 and the liquid holding mechanism...

Embodiment 2

[0040]The structure of the fast 3D printing device described in this embodiment is consistent with that of Embodiment 1, the main difference is that in this embodiment, in the fast printing method of the 3D printing device in the curing process described in step 2, the printing platform 42 pauses for 0.5 seconds and then Rising at a constant speed, the material tank 51 stops at a constant speed for 0.5 seconds and then rotates at a constant speed. The pause time of the printing platform 42 and the material tank 51 is generally determined according to the cross section of the printed item (that is, the area of the solidified layer) and the curing time of the printing solution. Generally, the printing platform stops for 0.1S-1S, and the material tank stops for 0.2S-1S. When the area of the solidified layer is small and the printing solution is solidified quickly, the printing platform 42 and the material tank 51 can move at a constant speed without stopping to realize fast pr...

Embodiment 3

[0042] The structure of the fast 3D printing device described in this embodiment is basically the same as that of Embodiment 1, the main difference is that the exposure mechanism 2 described in this embodiment adopts an LCD display device, and the LCD display screen of the LCD display device is located in the material tank as the exposure port. below. The curing principle of the LCD display device: using the LCD display imaging principle, driven by the LCD display device, a selective transparent area appears on the LCD display according to the printed image, and under the irradiation of the ultraviolet light source of the LCD display device, the LCD display The transparent area of the image has reduced UV blocking, and in the area where no image is displayed, the UV light is blocked. The ultraviolet light passing through the LCD display screen forms the ultraviolet light image area, and the above ultraviolet light is irradiated to the printing solution through the transparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com