Methane low-temperature combustion catalyst for boiling-bed reactor as well as preparation method and application of methane low-temperature combustion catalyst

A ebullated bed reactor and low-temperature combustion technology, which is applied in the fields of environmental protection and chemical engineering, to achieve the effects of high water absorption, increased load capacity, and uniform dispersion of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the methane low-temperature combustion catalyst provided in this embodiment comprises the following steps:

[0034] Aluminum hydroxide with a particle size of 20-200 μm is roasted at 750°C for 6 hours and then used as a microspherical carrier; lanthanum nitrate, calcium nitrate, cobalt nitrate, manganese nitrate and citric acid are prepared as the precursor of the perovskite active component Body solution; wherein the metal ion lanthanum: calcium: cobalt: the molar ratio of manganese is 9:1:5:5, and the ratio of citric acid to the total molar weight of metal ions (lanthanum, calcium, cobalt, manganese) is 1:1 , the perovskite active component precursor solution was loaded on the microspherical carrier with a loading rate of 5%, dried at 60°C for 5h, and then calcined at 700°C for 4.5h to obtain catalyst A.

Embodiment 2

[0036] The preparation method of the methane low-temperature combustion catalyst provided in this embodiment comprises the following steps:

[0037] Aluminum hydroxide with a particle size of 20-200 μm is roasted at 1100°C for 1.5 hours and then used as a microspherical carrier; lanthanum nitrate, strontium nitrate, cobalt nitrate, manganese nitrate and citric acid are used to make perovskite active components Precursor solution; wherein the molar ratio of metal ions lanthanum: strontium: cobalt: manganese is 7:3:5:5, and the ratio of citric acid to the total molar weight of metal ions (lanthanum, strontium, cobalt, manganese) is 0.5 : 1, loading the perovskite active component precursor solution on the microspherical carrier with a loading rate of 30%, drying at 60°C for 12h, and roasting at 900°C for 2h to obtain catalyst B.

Embodiment 3

[0039] The preparation method of the methane low-temperature combustion catalyst provided in this embodiment comprises the following steps:

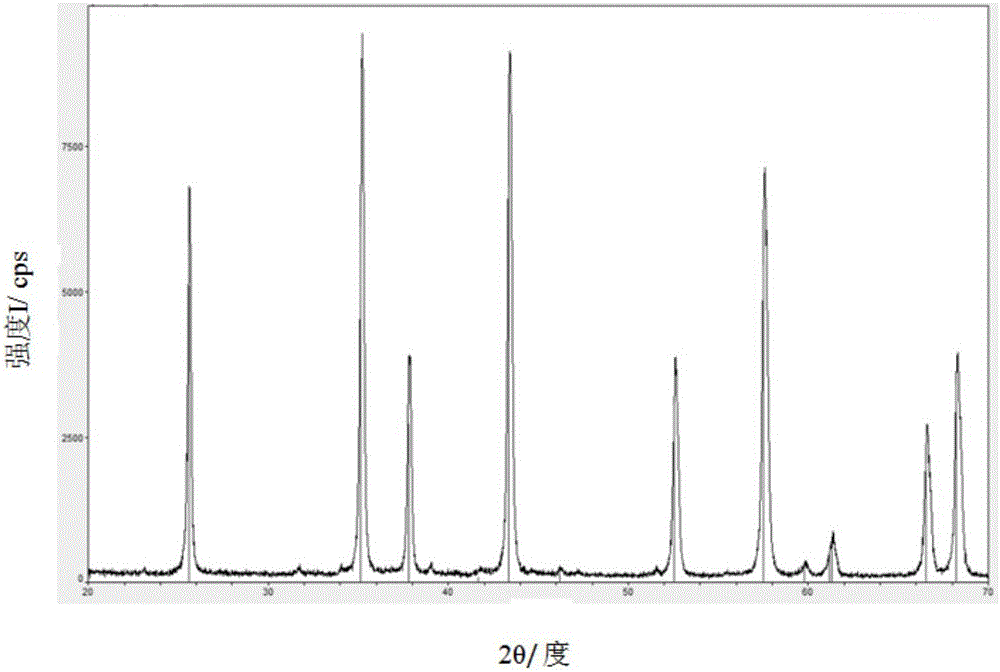

[0040] κ-Al obtained by calcining aluminum hydroxide with a particle size of 20-200 μm at 1200 ° C for 0.5 h 2 o 3 and α-Al 2 o 3 Alumina of mixed crystal phase is used as microsphere support (such as figure 1 shown); Lanthanum nitrate, barium nitrate, copper nitrate, manganese nitrate and lactic acid are made into the precursor solution of perovskite type active component; Wherein metal ion lanthanum: barium: copper: the molar ratio of manganese is 5: 5:1:9, the total molar ratio of lactic acid to metal ions (lanthanum, strontium, cobalt, manganese) is 2:1, the perovskite active component precursor solution is loaded on the microspherical carrier, and the loading rate is 2%, dried at 120°C for 1.0h, and then calcined at 1000°C for 1.0h to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com