Acetylene hydrogenation catalyst and preparation method thereof

An acetylene hydrogenation and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low activity of acetylene hydrogenation catalysts, and achieve good industrial Application prospects, good dispersion and stability, and the effect of improving hydrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] According to the preparation method of the acetylene selective hydrogenation catalyst provided by the invention, the preparation method comprises:

[0025] (1) treating the carrier with an alkaline solution, and then roasting to obtain the carrier Z;

[0026] (2) loading the main active component palladium precursor on the carrier Z to obtain a semi-finished catalyst;

[0027] (3) Mixing and contacting the semi-finished catalyst with a solution containing a free radical scavenger, and then performing ionizing radiation on the semi-finished catalyst to reduce the palladium to simple substance.

[0028] According to the present invention, preferably, in step (1), the embodiment of treating the carrier with the alkaline solution is spraying or dipping.

[0029] In the present invention, there is no special requirement for the alkaline solution, and it can be any solution with a pH value>7.

[0030] According to the present invention, preferably, the alkaline solution is ...

Embodiment 1

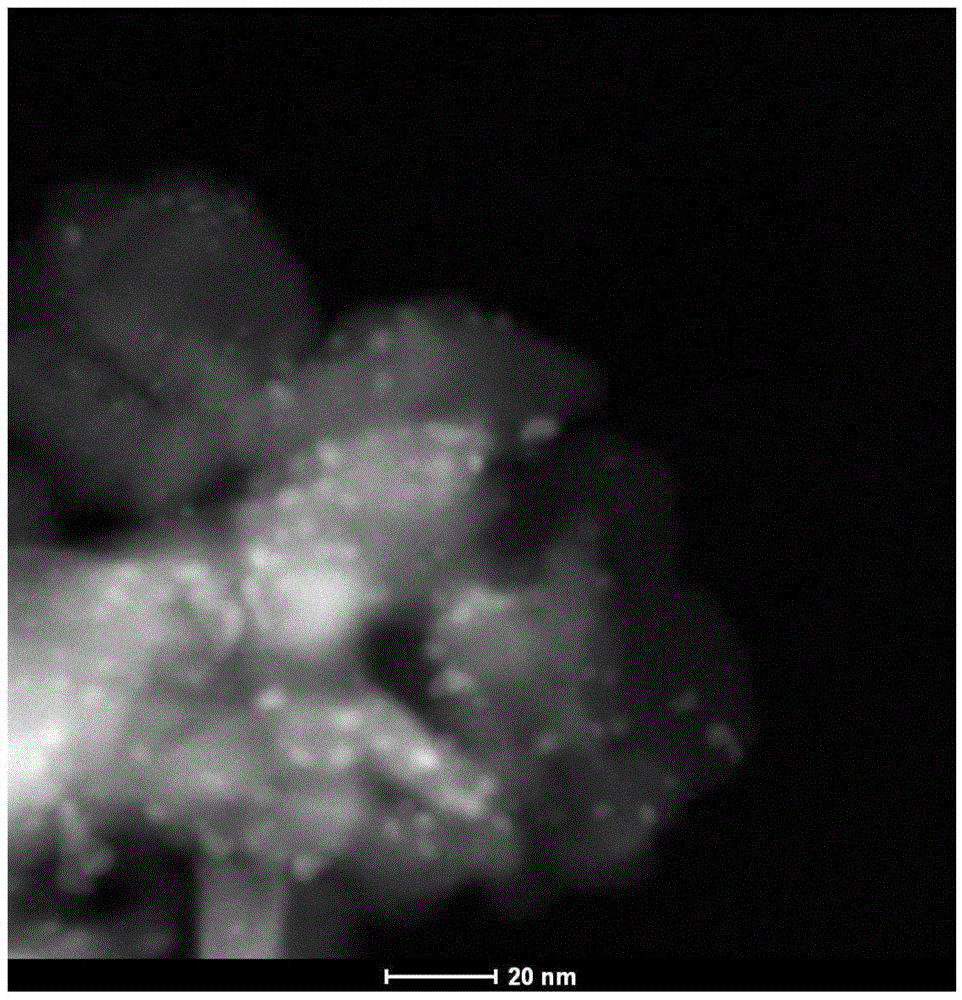

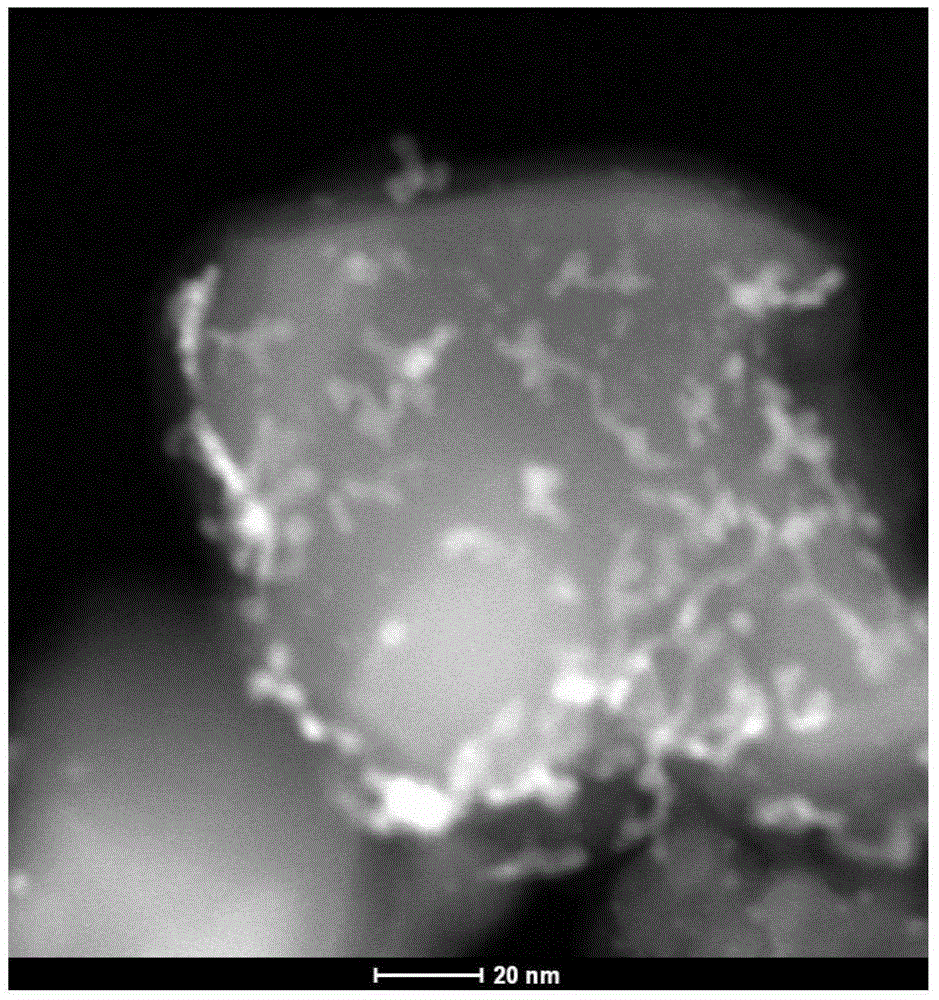

[0074] Take 50mL of NaOH solution with a concentration of 2mol / L and spray evenly on 100g of toothed spherical Al 2 o 3 The surface of the carrier was calcined at 850° C. for 3 hours to obtain the carrier Z1. Weigh 10mL of Pd(NO 3 ) 2 Solution, diluted to 25mL with deionized water, added 25mL of AgNO with a concentration of 2mgAg / mL 3 The solution is mixed evenly and then sprayed onto the carrier Z1 to obtain a semi-finished catalyst. Soak the semi-finished catalyst in a solution composed of 50mL deionized water and 50mL isopropanol, and use it under vacuum 60 The Coγ radiation source was irradiated for 10 hours at a dose rate of 30Gy / min. After irradiation, the sample was dried at 120° C. for 12 hours to obtain catalyst S1, which contained 0.05% by weight of Pd and had a molar ratio of Ag to Pd of 1. The scanning transmission electron microscope (STEM) photograph of catalyst S1 is shown in figure 1 As shown, the white bright spots in the figure are Pd particles. It can...

Embodiment 2

[0084] 100g tooth spherical Al 2 o 3 The carrier was impregnated in 100 mL of KOH solution with a concentration of 0.25 mol / L, and calcined at 700° C. for 6 hours to obtain carrier Z2. Weigh 8 mL of Pd(NO 3 ) 2 Solution, diluted to 30mL with deionized water, sprayed onto carrier Z2, then weighed 7mL of HAuCl with a concentration of 2mgAu / mL 4 The solution was diluted to 20 mL with deionized water, and sprayed onto the carrier Z2 to obtain a semi-finished catalyst. Soak the semi-finished catalyst in a solution composed of 50mL deionized water and 50mL formic acid, and use it under vacuum 60 The Coγ radiation source was irradiated for 10 hours at a dose rate of 30Gy / min. After irradiation, the sample was dried at 80° C. for 24 hours to obtain a catalyst S2 with a Pd element content of 0.04% by weight and a molar ratio of Au element to Pd element of 0.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com