Power-assisted steering oil composition

An oil composition, power steering technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of abnormal wear in the start-up stage, there is no power steering oil in extremely cold areas, frequent problems, etc., and achieve the best low temperature fluidity and The effect of excellent viscosity-temperature, susceptibility, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

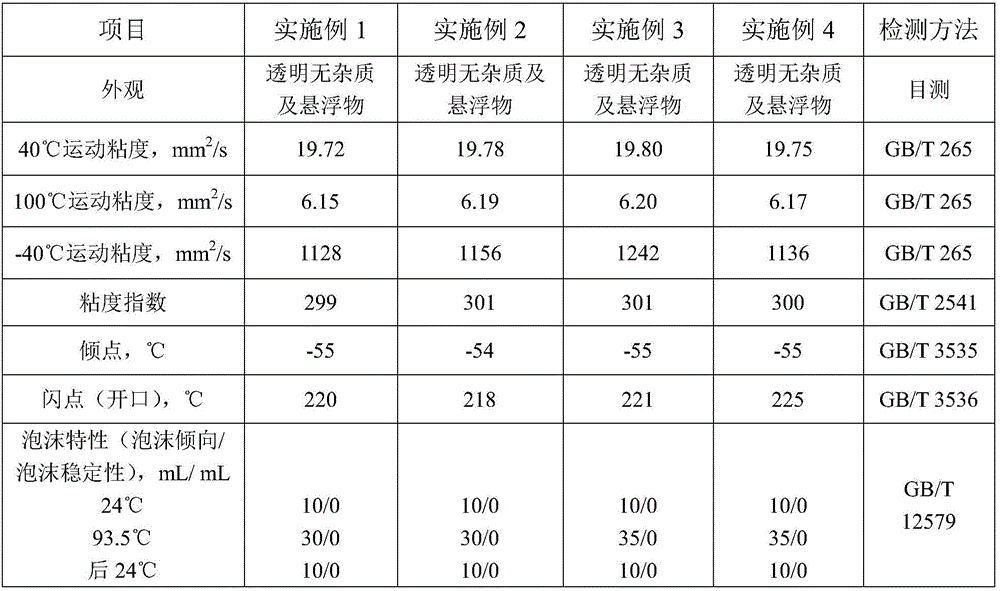

Examples

Embodiment 1

[0042] Choose to account for the base oil of 94.5% of the total weight of the present invention, 0.195% of polyisobutylene bis-succinimide, 0.5% of polymethyl methacrylate, 0.03% of tolyltriazole derivatives, 4% of styrene Polyester, 0.5% sulfurized isobutylene, 0.08% dialkyl diphenylamine, 0.03% neutral trimethylphenol phosphate, 0.005% composite antifoaming agent, 0.04% high base value synthetic calcium sulfonate, 0.04 % medium alkali value synthetic calcium sulfonate, 0.08% neutral barium dinonyl naphthalene sulfonate; the base oil is selected from adipate glycol ether ester accounting for 66.14% of the total weight of the base oil, accounting for 33.86% of the total weight of the base oil PAO2. Preparation method: Turn on the gear pump, open the feed valve, start stirring, put in the base oil first, then put in various additives in turn, after feeding, raise the temperature to 55°C, keep for 4 hours until all the additives are mixed evenly.

Embodiment 2

[0044]Choose to account for the base oil of 94.005% of the total weight of the present invention, 0.09% polyisobutylene polysuccinimide, 0.05% monosuccinimide, 0.3% polyacrylate, 0.2% polyalpha-olefin, 0.04 % of tolyltriazole derivatives, 4.5% of poly-n-butyl vinyl polyether, 0.2% of di-n-butyl phosphite, 0.3% of triphenyl thiophosphate, 0.06% of copper-containing salt compounds, 0.05% Zinc Dialkyl Dithiophosphate, 0.005% Simethicone, 0.04% Low Base Value Synthetic Calcium Sulfonate, 0.06% Low Base Value Calcium Petroleum Sulfonate, 0.1% Sodium Petroleum Sulfonate; base oil The adipate glycol ether ester accounting for 68.09% of the total weight of the base oil, the PAO2 accounting for 26.59% of the total weight of the base oil, and the PAO4 accounting for 5.32% of the total weight of the base oil are selected for use. Preparation method: Turn on the gear pump, open the feed valve, start stirring, put in the base oil first, then put in various additives in turn, after feeding,...

Embodiment 3

[0045] Select the base oil that accounts for 93.525% of the total weight of the present invention, 0.3% polymer succinimide, 0.4% vinyl acetate copolymer, 0.03% thiadiazole derivatives, 2% polymethacrylate, 3% polyisobutylene, 0.4% aminothioester, 0.1% copper-containing salt compound, 0.08% bis-octyl ZDDP, 0.005% simethicone, 0.04% super-based synthetic magnesium sulfonate, 0.04% Sulfurized alkyl phenate, 0.08% dodecenyl succinic acid; base oil selection accounted for 64.27% of the total weight of the base oil adipate glycol ether ester, accounted for 30.47% of the total weight of the base oil PAO2, accounting for the base oil Total weight 5.26% PAO6. Preparation method: Turn on the gear pump, open the feed valve, start stirring, put in the base oil first, then put in various additives in turn, after feeding, raise the temperature to 55°C, keep for 4 hours until all the additives are mixed evenly. Example 4,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com