Ship LNG vaporization system supplying heat through river water

A technology for river water and ships, applied in the field of ship LNG vaporization system, can solve the problems of lower thermal efficiency, lower working efficiency of LNG vaporizer, heat loss, etc., and achieve the effect of high freezing point and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

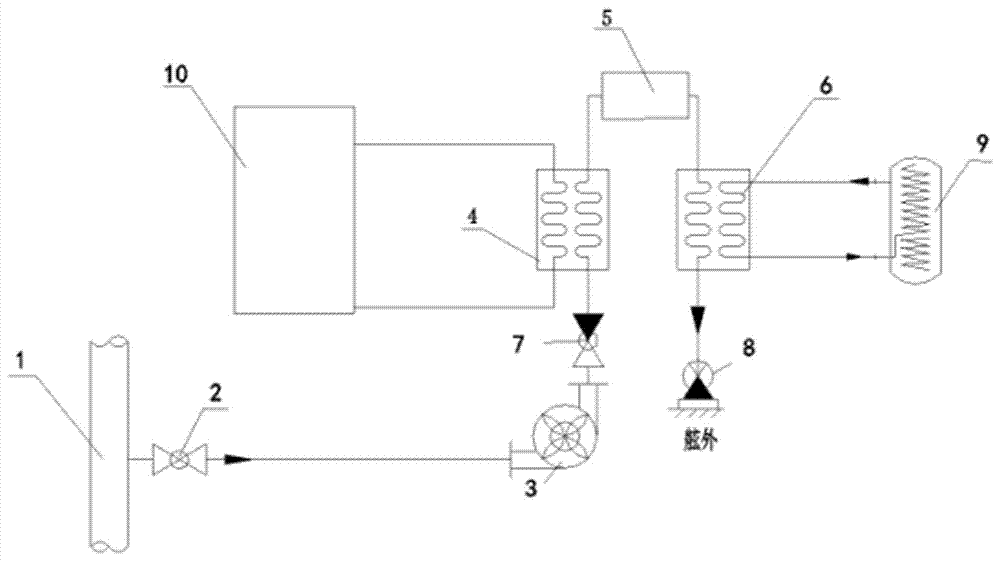

[0018] The ship LNG vaporization system using river water for heating includes a river water main pipe 1, a stop valve 2, an external cooling pump 3, an intercooler 4, a smoke exhaust water jacket 5, an ethylene glycol heat exchanger 6, and a stop check valve A7, stop check valve B8, LNG carburetor 9 and internal combustion engine 10, the river water main pipe 1 is connected with the external cooling pump 3 through the stop valve 2, and the external cooling pump 3 exchanges heat with the heat generated by the internal combustion engine 10 through the stop check valve A7 The intercooler 4 is connected, the intercooler 4 is connected with the water inlet end of the smoke exhaust water jacket 5, the water outlet end of the smoke exhaust water jacket 5 is connected with the ethylene glycol heat exchanger 6, and the ethylene glycol heat exchanger 6 is connected with the LNG vaporizer 9 , The drain of the glycol heat exchanger 6 is equipped with a stop check valve B8.

[0019] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com