Method for preparing aramid-pulp composite master batches

A technology of aramid pulp and masterbatch, which is applied in the field of preparation of aramid pulp composite masterbatch, which can solve the problems of microfiber entanglement and unfavorable pulp dispersion, and achieve lower specific surface energy, better mechanical properties and simplified process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

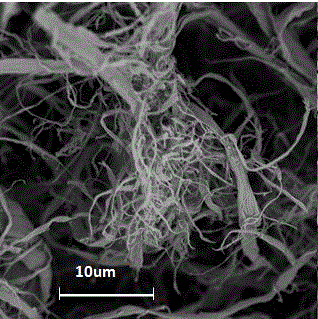

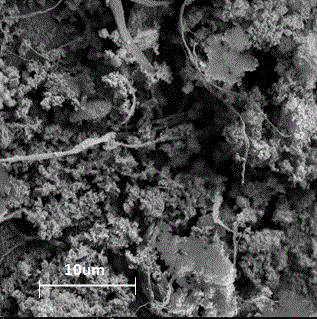

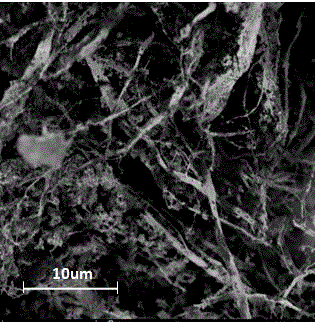

Image

Examples

Embodiment 1

[0032] (1) Add 20 parts by mass of para-aramid pulp to 1000 parts by mass of the water phase, and stir fully at 2000 r / min until there is no obvious agglomeration;

[0033] (2) Weigh 20 parts by mass of tetraethoxysilane (TEOS) and dissolve it in absolute ethanol to prepare a solution with a mass fraction of 50%. Then add it to (1) and stir evenly at a speed of 2000r / min. Subsequently, an ethanol solution of n-butylammonium with a mass fraction of 25% was added dropwise to the solution, and the batch pH of the solution was maintained at 10, 30° C., stirring for 3 hours, and then standing for 15 hours.

[0034] (3) Subsequently, 2 parts by mass of 3-aminopropyltriethoxysilane coupling agent was added dropwise to the solution, and stirred at a rotation speed of 1000r / min for 5h at room temperature.

[0035] (4) After the mixture is dehydrated and vacuum-dried in a vacuum drying cabinet at 100°C, it is subjected to high-speed fluffing treatment in a high-speed blender at a speed of 300...

Embodiment 2

[0038] (1) Add 10 parts by mass of para-aramid pulp to 300 parts by mass of the water phase, and stir fully at 1000r / min until there is no obvious agglomeration;

[0039] (2) Weigh 20 parts by mass of tetraethoxysilane (TEOS), and dissolve it in absolute ethanol to prepare a solution with a mass fraction of 30%. Then add it to (1) and stir evenly at a speed of 800r / min. Then add dropwise a 10% mass fraction of n-butylammonium solution to the solution, keep the pH of the solution at 8, 500r / min at 50℃, stir for 2h, and then stand for 10h;

[0040] (3) Then add 1 part by mass of γ-methacryloxypropyltrimethoxysilane coupling agent to the solution, and stir for 3h at room temperature 800r / min;

[0041] (4) After dehydrating the mixture and vacuum drying in a vacuum drying oven at 80°C, perform high-speed fluffing treatment in a high-speed blender at a speed of 2000r / min for 4min;

[0042] (5) Mix 100 parts by mass of polypropylene particles with (4) treated pulp, 0.1 parts of antioxidant...

Embodiment 3

[0056] The aramid pulp composite precursors prepared in the above examples and comparative examples were used to reinforce the corresponding matrix materials. First, use a twin-screw extruder to directly blend different amounts of composite masterbatch with the corresponding matrix, then melt blend, extrude, pelletize, and dry, and then inject the resulting pellets into standard specimens with an injection molding machine. The performance test results are shown in Table 1 (comparison between Example 1 and Comparative Example 1, and contrast between Example 2 and Comparative Example 2):

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com