PP composite material with low VOC and preparation method thereof

A technology of composite materials and parts by weight, which is applied in the field of automotive materials, can solve the problems of materials not having low VOC, and achieve the effects of low preparation cost, simple compounding process and processing process, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

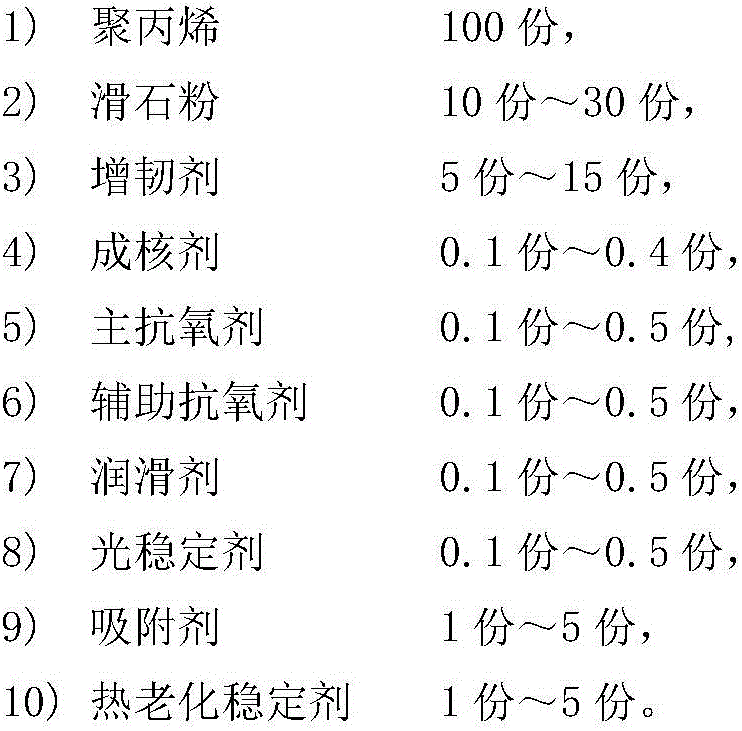

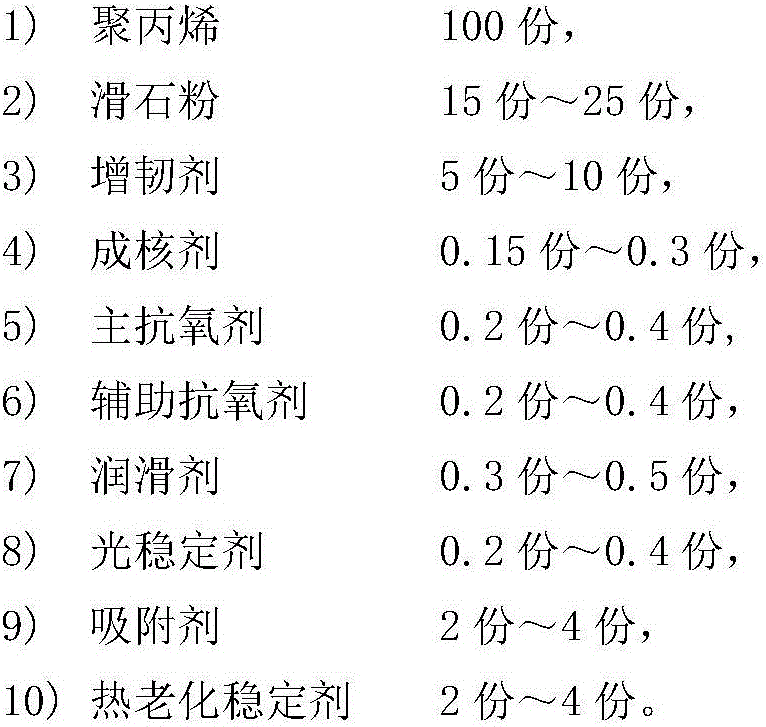

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of making the PP composite material of low VOC according to above-mentioned component distribution ratio, steps are as follows:

[0056] 1) take each component by weight parts;

[0057] 2) Mix the polypropylene, toughening agent, nucleating agent, primary antioxidant, auxiliary antioxidant, light stabilizer, heat-resistant aging agent, lubricant, and adsorbent in a high-speed mixer for 3 minutes ~5 minutes, then add talcum powder and mix for 5 minutes to 10 minutes;

[0058] 3) Put the mixed material into the main feeding port of the twin-screw extruder with a length-to-diameter ratio of 36:1-42:1, melt and extrude to granulate, and the extruded material is cooled, air-dried, pelletized and dried , that is, the finished product, wherein, the twin-screw extruder adopts an extruder with seven working temperature zones, the temperature setting range is 170°C-200°C, the screw speed is 200rpm-500rpm, and the end vacuum is -0.06MPa ~-0.09MPa.

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com