High-concentration molybdenum disulfide nanometer sheet dispersion liquid, and preparation method and application thereof

A nano-dispersion, molybdenum disulfide technology, applied in the direction of molybdenum sulfide, electrodes, electrical components, etc., can solve the problems of poor stability, easy agglomeration of molybdenum sulfide nanosheets, etc., and achieve an easy-to-operate, suitable for large-scale, effective and fast preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

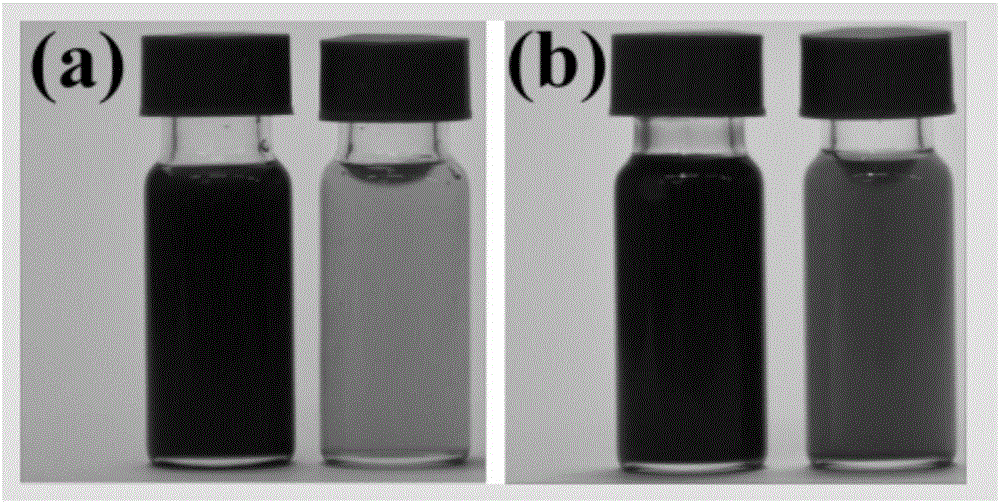

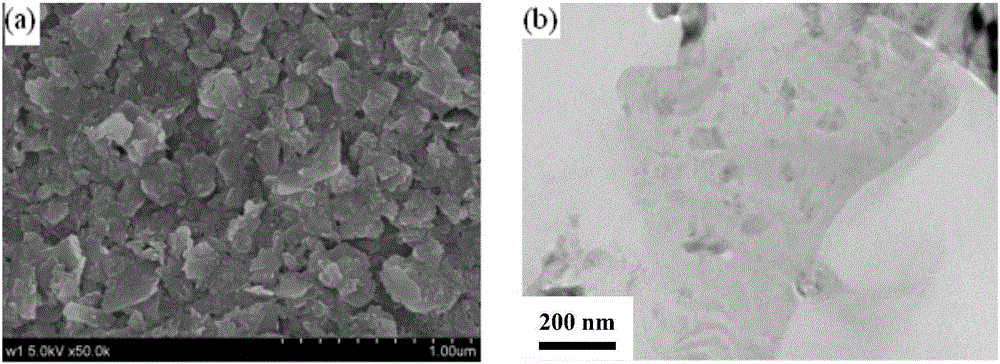

[0032] (1) Add 2 g of molybdenum sulfide (molybdenite) to 1000 ml of N-vinylpyrrolidone, use an experimental cell pulverizer for continuous ultrasonication for 8 hours (the ultrasonic program is 7 seconds at work, 3 seconds at intervals), and the supernatant is taken Liquid centrifugation to obtain a uniform dispersion, which is molybdenum sulfide nanosheets; wherein, the concentration of the dispersion is 0.6mg / ml;

[0033] (2) Take the above dispersion, centrifuge at 8000 rpm for 20 minutes, pour off the upper suspension, add N-vinylpyrrolidone and re-sonicate for 30 minutes to disperse evenly;

[0034] (3) Take the above-mentioned dispersion and centrifuge at a speed of 1500 rpm for 20 minutes, and take the upper layer suspension to be the molybdenum sulfide nanosheet dispersion.

[0035] (4) Take the above-mentioned dispersion liquid by suction filtration, wash with 30mL deionized water and 30mL ethanol alternately for 3 times and then wash with 150mL deionized water to ob...

Embodiment 2

[0043] (1) Add 3g of molybdenum sulfide ore (molybdenite) to 800 ml of dimethylformamide, use an experimental ultrasonic cleaning machine to ultrasonicate for 8 hours (the ultrasonic program is to work for 1 hour, intermittently for 30 minutes), and take the supernatant Centrifuge to obtain a uniform dispersion, which is molybdenum sulfide nanosheets; wherein, the concentration of the dispersion is 0.5mg / ml;

[0044] (2) Take the above dispersion, centrifuge at 9000 rpm for 15 minutes, pour off the upper suspension, add dimethylformamide and re-sonicate for 25 minutes to disperse evenly;

[0045] (3) Take the above-mentioned dispersion liquid and centrifuge it at a speed of 2000 rpm for 30 minutes, and take the upper suspension liquid to be the molybdenum sulfide nanosheet dispersion liquid.

[0046] (4) Take the above-mentioned dispersion liquid by suction filtration, wash with 30mL deionized water and 30mL ethanol alternately for 3 times and then wash with 150mL deionized wa...

Embodiment 3

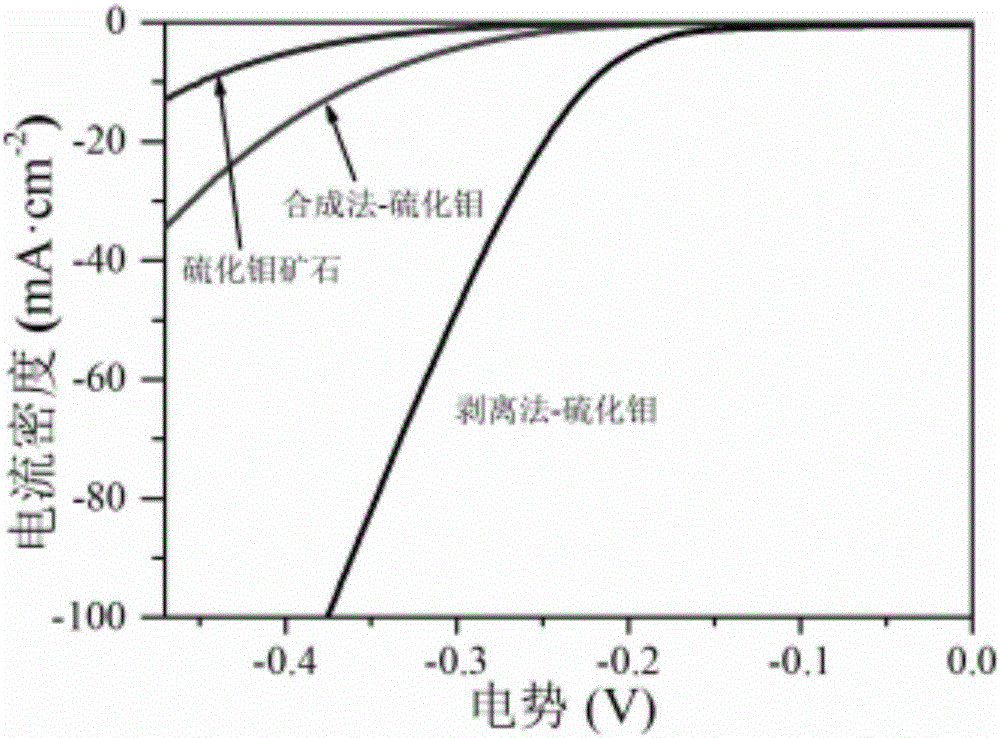

[0049] (1) Get the binder polyvinylidene fluoride (PVDF) solution (solvent is N-methylpyrrolidone) of molybdenum sulfide nanoplate dispersion liquid 5mL, 2.35mg conductive carbon black and 100mg 2wt% in embodiment 2, they are in Grind by hand in a mortar for 5 minutes and set aside.

[0050] (2) Use a glass rod to evenly coat the prepared slurry above on the fully dried current collector (copper foil). After the coating is uniform, move the current collector into an electric blast drying oven at 70°C to dry for 6 hours. After fully drying The electrode sheets are stamped into small discs with a certain diameter by a manual button cell slicer.

[0051] (3) In the glove box, use the above-mentioned electrode sheet as the negative electrode and the lithium sheet as the positive electrode, select the Celgard-2400 diaphragm, and assemble the 2032 button cell with LB303 electrolyte. Finally, the assembled battery is sealed with a button-type automatic sealing machine, and the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com