Distillate oil hydrofining catalyst carrier and preparation method thereof

A catalyst carrier and hydrorefining technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor coking resistance and stability, and uneven pore size distribution, and achieve uniform distribution and pore size. The effect of concentrated distribution and improved pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

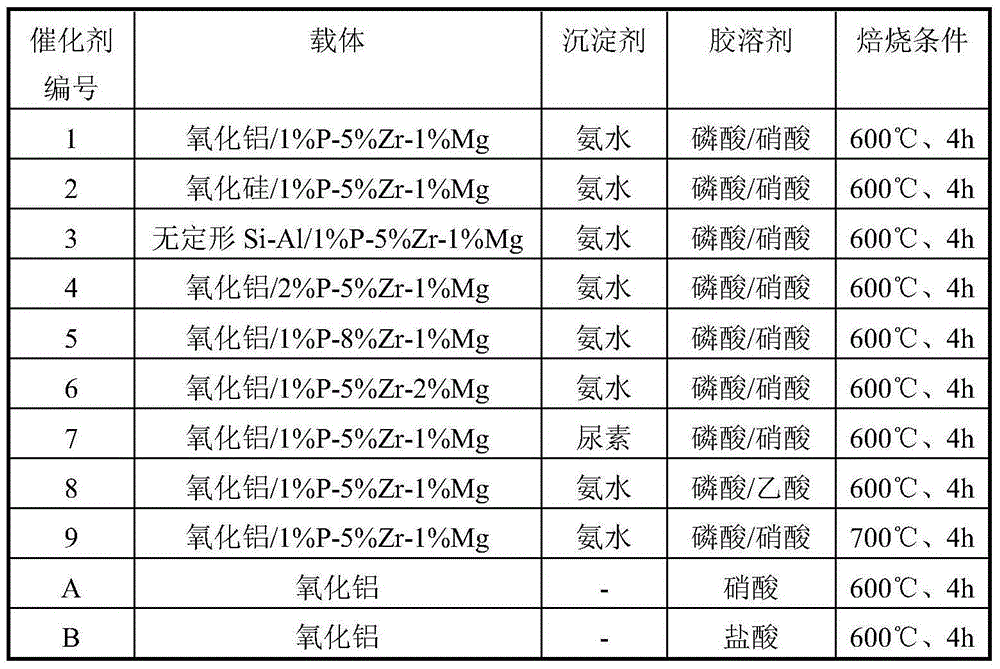

Embodiment 1

[0032] Mix the large-pore pseudo-boehmite (Shandong Zibo Qilin Chemical Industry Co., Ltd.) with a dry basis of 80 g and the small-pore pseudo-boehmite (Shandong Zibo Qilin Chemical Industry Co., Ltd.) with a dry basis of 20 g and add 1 L of water to make a slurry. After 30 minutes, respectively Add zirconium nitrate and magnesium nitrate (including Zr 5g, Mg 1g) to the slurry, raise the temperature to 60°C during the stirring process, keep the temperature for 1 hour, add ammonia water to the slurry to adjust the pH value to 10, and then stir for 1 hour before suction filtration After washing and drying overnight, add 5 g of kale powder to the dry powder and mix evenly, then add a solution (containing 1 g of P) consisting of phosphoric acid, nitric acid and 60 g of deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die, and the shape is a slender cylinder (cross-sectional diameter 1.5mm), dried at 120°C and calcined at 600°C for 4...

Embodiment 2

[0034] Mix silicon oxide (Zibo, Shandong) with a dry basis of 80 g and small-pore pseudoboehmite (Zibo Qilin Chemical Industry, Zibo, Shandong) with a dry basis of 80 g and add 1 L of water to make a slurry. After 30 minutes, add zirconium nitrate and nitric acid to the slurry Magnesium (including Zr 5g, Mg 1g), the temperature was raised to 60°C during the stirring process, and after constant temperature for 1 hour, ammonia water was added to the slurry to adjust the pH value to 10. After adding 5g of scallop powder and mixing evenly, add a solution (containing P 1g) consisting of phosphoric acid, nitric acid and 60g of deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die, and the shape is a slender cylinder (cross-sectional diameter 1.5mm), dried at 120°C and calcined at 600°C for 4 hours, and then cut into carrier particles (1.5×4.0mm) of the same size. Final carrier material 2.

Embodiment 3

[0036] Mix amorphous silica-alumina (Zibo, Shandong) with a dry basis of 80 g and small-pore pseudoboehmite (Zibo Qilin Chemical Industry, Shandong) with a dry basis of 20 g, and add 1 L of water to make a slurry, and add zirconium nitrate to the slurry after 30 minutes and magnesium nitrate (containing 5g of Zr and 1g of Mg), the temperature was raised to 60°C during the stirring process, and after constant temperature for 1h, ammonia water was added to the slurry to adjust the pH value to 10, and then stirred for 1h, then suction filtered, washed, and dried overnight. Add 5g of scallop powder to the dry powder and mix evenly, then add a solution (containing 1g of P) consisting of phosphoric acid, nitric acid and 60g of deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die, and the shape is a slender cylinder (cross-sectional diameter 1.5mm), dried at 120°C and calcined at 600°C for 4 hours, and then cut into carrier particles (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com