A carbon dioxide-assisted bipolar membrane electrodialysis system and production method for amino acid production

A bipolar membrane electrodialysis, carbon dioxide technology, applied in electrodialysis, chemical instruments and methods, membrane technology, etc., can solve problems such as increasing production costs, improve recovery efficiency, expand industrial application potential, and reduce membrane pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

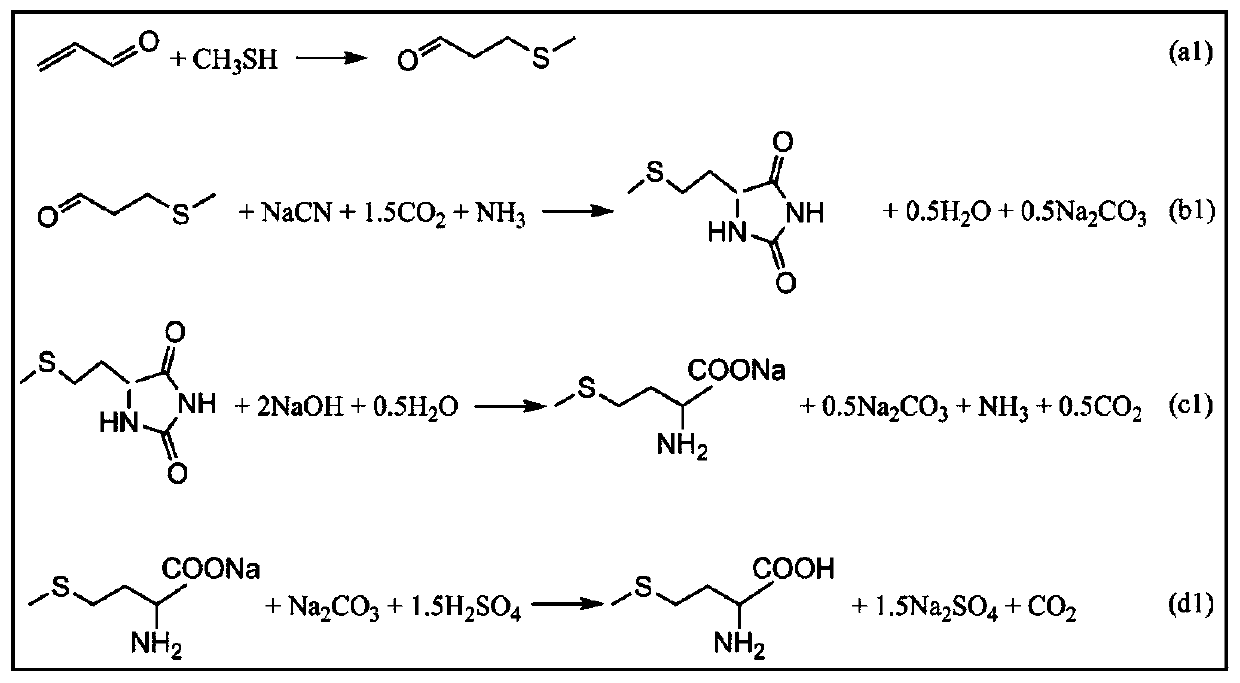

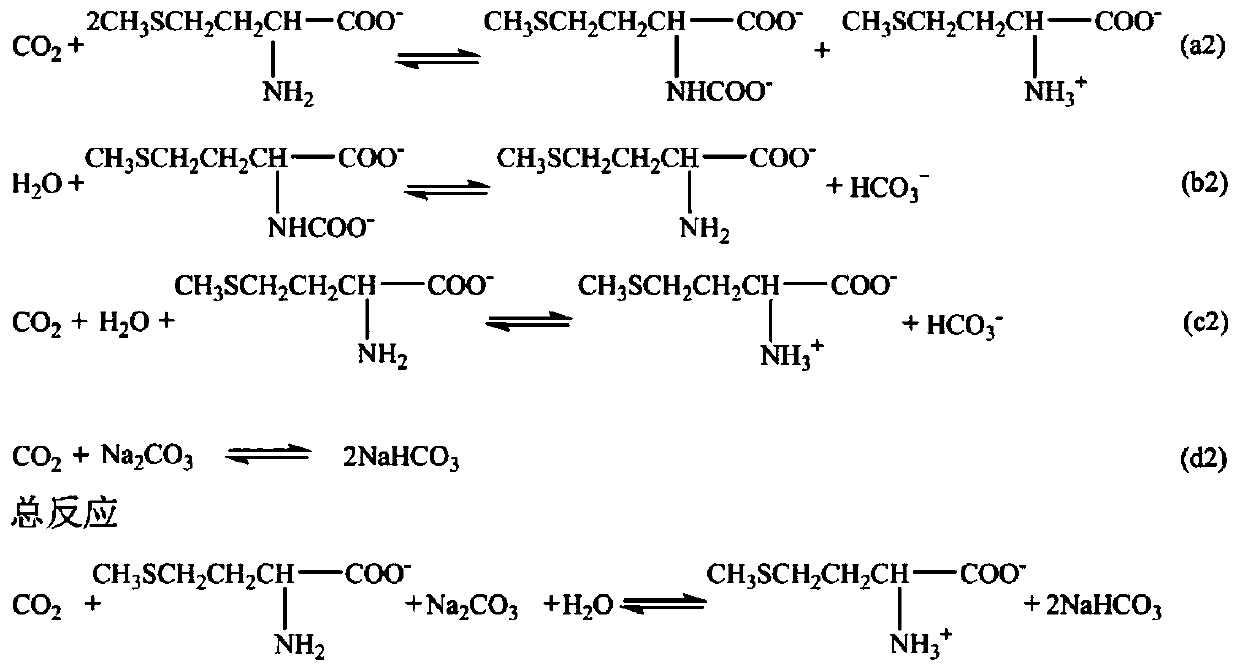

Method used

Image

Examples

Embodiment 1

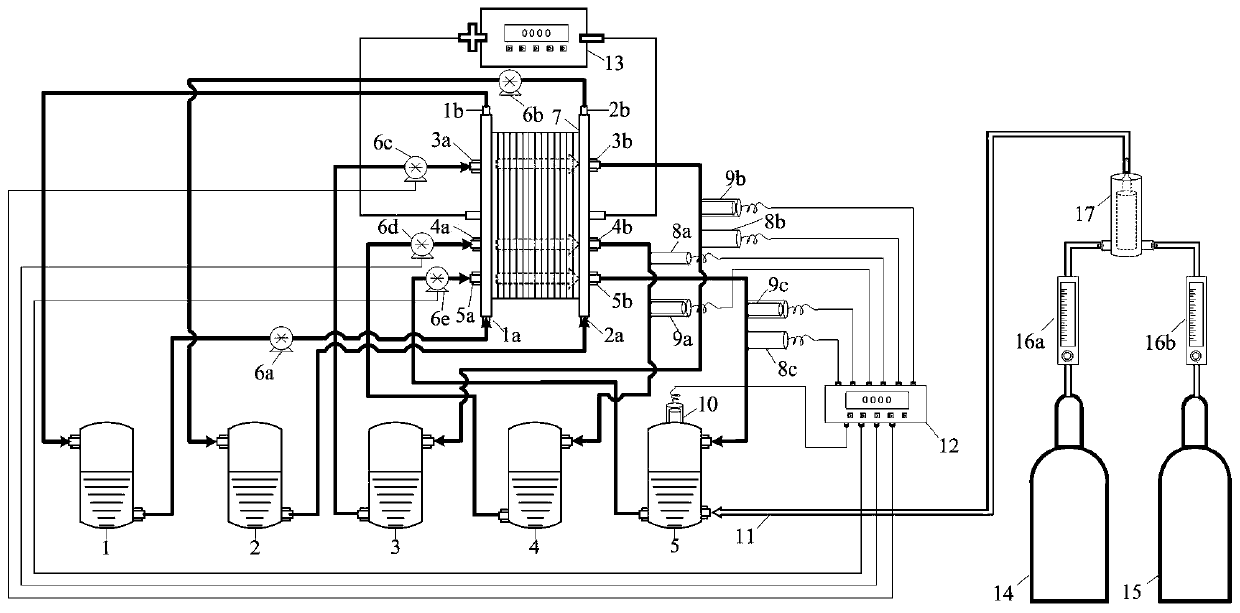

[0061] This embodiment utilizes the above-mentioned carbon dioxide-assisted bipolar membrane electrodialysis system to produce methionine, and the raw material used is a mixed solution of sodium methionine and sodium carbonate (wherein the concentration of sodium methionine is 0.1mol / L, and the concentration of sodium carbonate is 0.2mol / L), Use high-purity carbon dioxide gas as the carbon dioxide gas source.

[0062] Among them, the electrodialysis membrane stack used is composed of bipolar membranes, cation exchange membranes and anion exchange membranes alternately stacked in sequence, plus flow channel spacers and sealing gaskets. A total of four bipolar membranes, three cation exchange membranes, Three anion exchange membranes form three repeating units of "alkali chamber-feed liquid chamber-acid chamber" in the electrodialysis membrane stack. The bipolar membrane, anion exchange membrane and cation exchange membrane used in the process are respectively BP-I, JAM-II and J...

Embodiment 2

[0070] This embodiment utilizes the same carbon dioxide-assisted bipolar membrane electrodialysis system as in Example 1 to produce methionine, and the raw material used is a mixed solution of sodium methionine and sodium carbonate (wherein the concentration of sodium methionine is 0.1mol / L, and the concentration of sodium carbonate is 0.2mol / L), using simulated flue gas of 70% nitrogen + 30% carbon dioxide as the source of carbon dioxide.

[0071] The carbon dioxide gas source is mixed with high-purity carbon dioxide gas and high-purity nitrogen gas. The carbon dioxide gas tank 14 is connected to the carbon dioxide gas flow meter 16a, and the carbon dioxide gas intake flow rate is adjusted to 70-80mL / min. The nitrogen gas tank 15 is connected to the nitrogen gas flow rate. Meter 16b, adjust the nitrogen gas intake flow rate at 168-187mL / min, the carbon dioxide gas flow meter 16a and the nitrogen gas flow meter 16b are connected to the gas mixer 17 at the same time, and the ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com