Carbon dioxide colloidal foam fire extinguishing device

A technology of carbon dioxide and colloidal foam, which is applied in fire rescue and other fields, can solve the problems of occupying the jet flow of jet equipment, reducing the fire extinguishing efficiency of jet equipment, and increasing the resistance of transport and jet, so as to achieve the reduction of fire extinguishing cost, high fire extinguishing efficiency and fire extinguishing ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

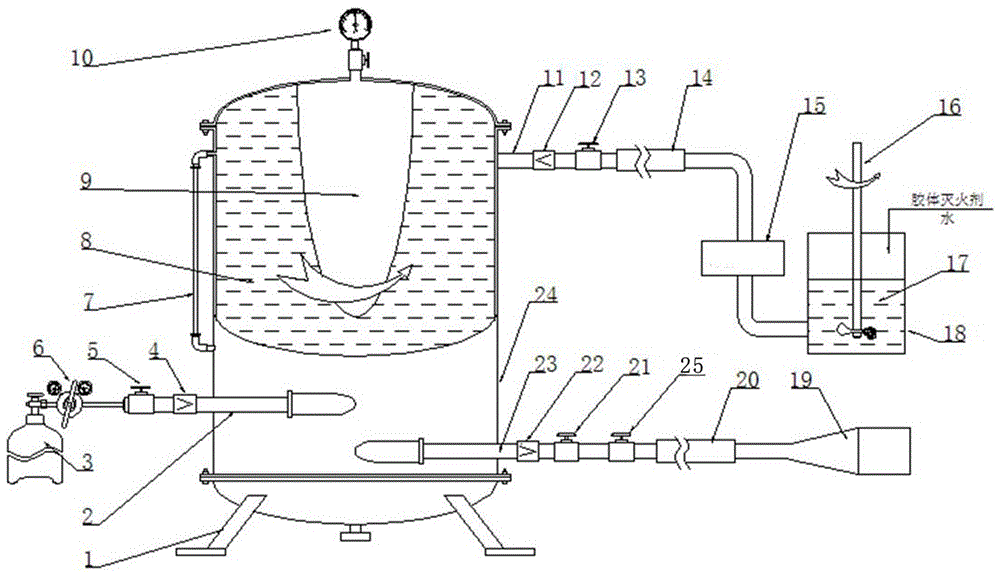

[0040] Embodiment 1 (plane oil fire extinguishing)

[0041] In an open field, dig a hole with a depth of 5-6mm and an area of about 1m 2 Cover the concave ground with a layer of plastic film, the edge of the plastic film exceeds the concave ground by about 10cm, and cover the excess with soil. Add diesel oil to the depression of the plastic film so that the oil surface can be covered with pits.

[0042] The fire extinguishing experiment process is as follows:

[0043] 1. Select the product of formula three. Add quantitative water into the dilution tank 18, start the agitator 16, then add the finished colloidal fire extinguishing agent in a ratio of 40:1, and stir well.

[0044] 2. Open the valve II13, and use the hydraulic pump 15 (0.6MPa) to deliver the diluent 17 to the mixing tank 24. When the liquid level reaches the middle and upper part of the liquid level gauge 7, close the hydraulic pump 15.

[0045] 3. Open the main valve of the liquid carbon dioxide cylinder, a...

Embodiment 2

[0051] Embodiment 2 (fire extinguishing by irregular oil surface combustion)

[0052] In an open field, dig a hole with a depth of 5-6mm and an area of about 1m 2 Cover the concave ground with a layer of plastic film, the edge of the plastic film exceeds the concave ground by about 10cm, and cover the excess with soil. Set up horizontal and vertical timbers in the depressions of the plastic film, then pour diesel oil, and make the oil surface be full of pits.

[0053] The fire extinguishing experiment process is as follows:

[0054] 1. Select the product of formula three. Add quantitative water into the dilution tank 18, start the agitator 16, then add the finished colloidal fire extinguishing agent in a ratio of 40:1, and stir well.

[0055] 2. Open the valve II13, and use the hydraulic pump 15 (0.6MPa) to deliver the diluent 17 to the mixing tank 24. When the liquid level reaches the middle and upper part of the liquid level gauge 7, close the hydraulic pump 15.

[005...

Embodiment 3

[0062] Embodiment 3 (non-oil fire extinguishing)

[0063] In an open space, build three walls with bricks and mud, with a height of 1.5m and a length of 1m. A 1mm thick steel plate is covered on the top, and a fire torch (dipped in oil), wood, foam plastic, and waste clothes are placed in it. , piled up into 40cm thick combustibles.

[0064] The fire extinguishing experiment process is as follows:

[0065] 1. Select the product of formula three. Add quantitative water into the dilution tank 18, start the agitator 16, then add the finished colloidal fire extinguishing agent in a ratio of 40:1, and stir well.

[0066] 2. Open the valve II13, and use the hydraulic pump 15 (0.6MPa) to deliver the diluent 17 to the mixing tank 24. When the liquid level reaches the middle and upper part of the liquid level gauge 7, close the hydraulic pump 15.

[0067] 3. Open the main valve of the liquid carbon dioxide cylinder, adjust the pressure reducing valve 6 to keep the mixed liquid level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com