Reagent and method for rapidly measuring ammonia nitrogen content of oil refining sewage through electrode method

A technology for rapid determination and oil refining sewage, applied in the direction of electrochemical variables of materials, etc., can solve the problems of complex, measurement interference, etc., to achieve the effect of simple configuration, accurate results, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The reagent of the electrode method of this embodiment to quickly determine the content of ammonia nitrogen in oil refinery sewage is composed of a standard solution and a buffer solution. The standard solution is an ammonium chloride solution, and the mass percent concentration of ammonium chloride in the standard solution is 10.956 g / L The buffer solution is a mixed solution of sodium hydroxide, potassium sodium tartrate tetrahydrate, disodium ethylenediamine tetraacetate, and the mass percentage concentration of each component in the buffer solution is as follows: sodium hydroxide: 40 g / L; Potassium tartrate Sodium tetrahydrate: 28.2 g / L; disodium edetate: 7.44 g / L.

[0019] The process of using the above reagent and electrode method to measure the concentration of ammonia nitrogen in oil refinery sewage is as follows:

[0020] A: Put 2ml of buffer solution into 50ml of the water sample to be tested, and stir, measure the potential of the water sample to be tested wi...

Embodiment 2

[0026] The mass percent concentration of the ammonium chloride in the standard solution in this embodiment is still 10.956 g / L, and the difference from Example 1 is that in this embodiment, the mass percent concentration of each component in the buffer solution is as follows : Sodium hydroxide: 100 g / L; Potassium sodium tartrate tetrahydrate: 70.5 g / L; Disodium edetate: 18.6g / L.

[0027] The measurement method of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0029] The mass percent concentration of ammonium chloride in the standard solution in this embodiment is still 10.956 g / L, and the difference from Examples 1 and 2 is that in this embodiment, the mass percent of each component in the buffer solution The concentrations are as follows: sodium hydroxide: 200 g / L; potassium sodium tartrate tetrahydrate: 141 g / L; disodium edetate: 74.4 g / L.

[0030] The measurement method of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

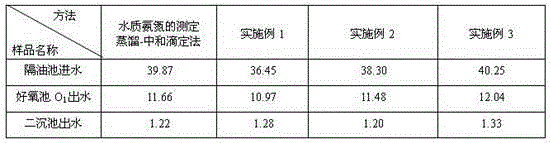

[0031] The water samples to be tested in the above-mentioned three embodiments are all oil trap inlet water and aerobic pool O in a certain oil refinery. 1 For the same batch of water samples of effluent and secondary sedimentation tank effluent, the reagents and methods of the above three implementations were compared with the measurement results of the standard method "Determination of Ammonia Nitrogen Distillation-Neutralization Titration". The results are shown in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com