Bamboo plastic composite for processing moistureproof, insect-damage-proof and antimicrobial type summer sleeping mat

A composite material and anti-moth technology, which is applied in the field of bamboo-plastic composite materials, can solve the problems of shortened service life and easy mildew of bamboo mats, and achieve the effects of prolonging service life, strong environmental protection, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

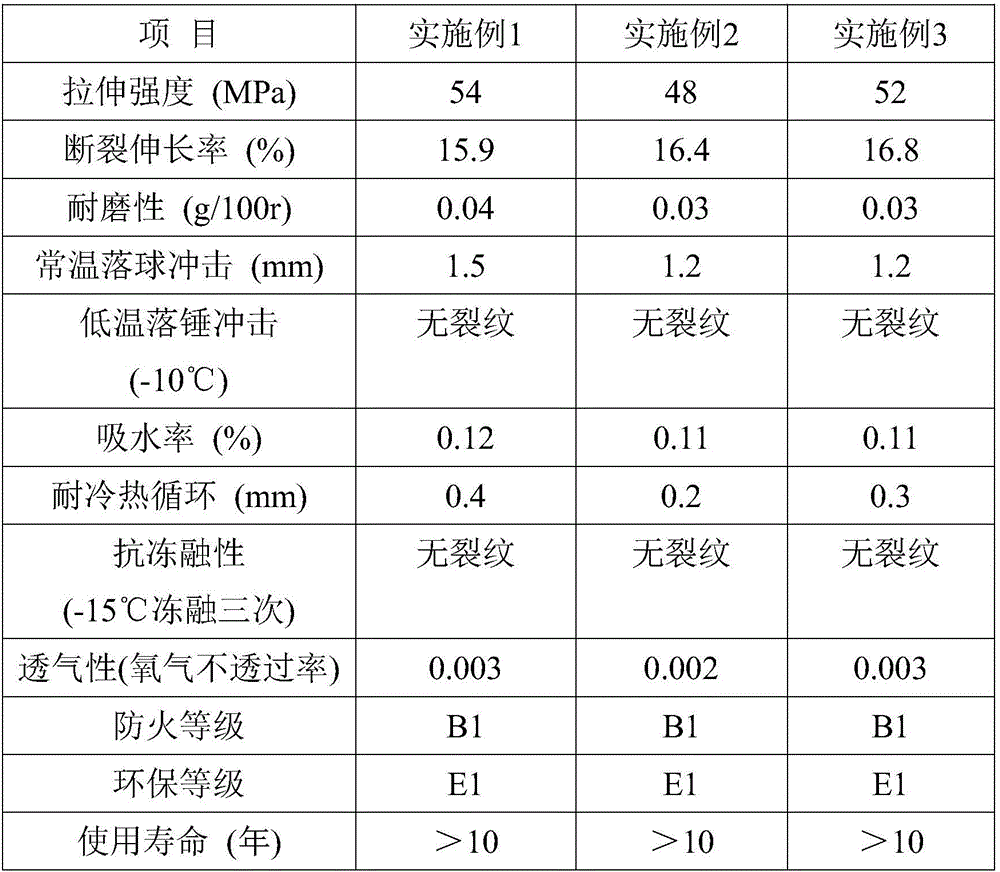

Examples

Embodiment 1

[0024] (1) Add 5 parts of terpene resin and 2 parts of powdered nitrile rubber to 10 parts of linear low-density polyethylene, mix thoroughly and add to the mixer, mix at 130-135°C for 5 minutes, and then add 0.5 part of double Trifluoromethanesulfonimide and 0.5 parts of methyl etherified hexamethylol melamine resin were mixed at 130-135°C for 3 minutes to obtain material I;

[0025] (2) Add 3 parts of methyl etherified amino resin and 2 parts of toughening agent to 15 parts of high-density polyethylene, mix thoroughly, add to the mixer, and mix at 125-130°C for 5 minutes to obtain material II;

[0026] (3) Add 5 parts of coconut bran and 3 parts of calcined kaolin to 20 parts of bamboo powder, and heat to 75-80℃ to keep and mix for 10min, then make powder by ultra-fine grinder, then add 1 part of nano talc powder and 1 part Octadecyl trimethyl ammonium chloride, after mixing thoroughly, keep it at 40-45℃ for 30 minutes, and then obtain material II;

[0027] (4) Add material II, 3 ...

Embodiment 2

[0031] (1) Add 5 parts of terpene resin and 2 parts of powdered nitrile rubber to 15 parts of linear low-density polyethylene, mix thoroughly and add to the mixer, mix at 130-135°C for 5 minutes, and then add 0.5 part of double Trifluoromethanesulfonimide and 1 part of methyl etherified hexamethylol melamine resin are mixed at 130-135°C for 3 minutes to obtain material I;

[0032] (2) Add 3 parts of methyl etherified amino resin and 3 parts of toughening agent to 10 parts of high-density polyethylene, mix them thoroughly, add them to the mixer, and mix at 125-130°C for 5 minutes to obtain material II;

[0033] (3) Add 5 parts of coconut bran and 3 parts of calcined kaolin to 25 parts of bamboo powder, and heat to 75-80℃ to keep and mix for 10min, then make into powder by ultra-fine grinder, then add 2 parts of nano talc powder and 1 part Octadecyl trimethyl ammonium chloride, after mixing thoroughly, keep it at 40-45℃ for 30 minutes, and then obtain material II;

[0034] (4) Add mat...

Embodiment 3

[0038] (1) Add 5 parts of terpene resin and 2 parts of powdered nitrile rubber to 15 parts of linear low-density polyethylene, mix thoroughly and add to the mixer, mix at 130-135°C for 5 minutes, and then add 0.5 part of double Trifluoromethanesulfonimide and 0.5 parts of methyl etherified hexamethylol melamine resin were mixed at 130-135°C for 3 minutes to obtain material I;

[0039] (2) Add 3 parts of methyl etherified amino resin and 3 parts of toughening agent to 15 parts of high-density polyethylene, mix thoroughly, add to the mixer, and mix at 125-130°C for 5 minutes to obtain material II;

[0040] (3) Add 5 parts of coconut bran and 5 parts of calcined kaolin to 25 parts of bamboo powder, heat to 75-80℃ and keep mixing for 10 minutes, then make powder by ultra-fine grinder, then add 1 part of nano talcum powder and 1 part One part of octadecyl trimethyl ammonium chloride, mixed thoroughly and kept standing at 40-45°C for 30 minutes to obtain material II;

[0041] (4) Add mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com