Hyperbranched hydroxyl polyester resin, and preparation method and application of hyperbranched hydroxyl polyester resin

A technology of hydroxypolyester resin and hydroxypolyester, which is applied in the field of fine chemical synthesis, can solve the problems of difficult control of the reaction end point, high acid value of hyperbranched polyester, and easy formation of gelled products, so as to reduce construction VOC emissions , high solubility and easy reaction end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

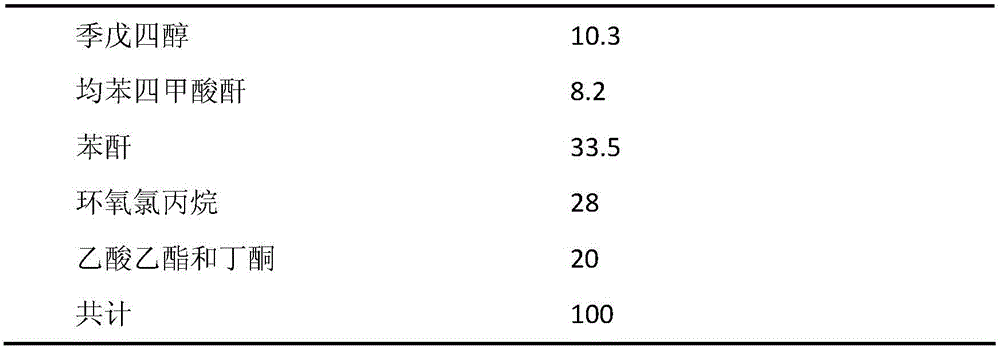

[0035] A kind of hyperbranched hydroxyl polyester resin (HBP-1), raw material formula mass percent composition is as table 1 (excluding catalyzer):

[0036] Table 1

[0037]

[0038] (2) The preparation technology of this hyperbranched hydroxyl polyester resin (HBP-1), comprises the following steps:

[0039] Mix pyromellitic dianhydride, pentaerythritol, and ethyl acetate uniformly in the reactor according to a given mass, and add catalyst p-toluenesulfonic acid (0.5% of the mass of the anhydride) to react for 2 hours at 120°C under nitrogen protection; Fixed mass of phthalic anhydride, reacted for 3h; added epichlorohydrin, and added catalyst tetraethylammonium bromide (1.0% of epoxy compound mass fraction) and butanone, reacted under nitrogen protection at 110°C for 4h until the acid value was less than 10mgKOH / g, cooling and discharging to obtain hyperbranched hydroxyl polyester resin (HBP-1). attachedfigure 1 It shows that the HBP-1 is the ideal structure of the firs...

Embodiment 2

[0050] (1) A kind of hyperbranched hydroxyl polyester resin (HBP-2), the mass percentage composition of raw material formula is as shown in Table 4 (excluding catalyst):

[0051] Table 4

[0052]

[0053] (2) The preparation technology of this hyperbranched hydroxyl polyester resin (HBP-2), comprises the following steps:

[0054] Mix pyromellitic anhydride, trimethylolpropane, and ethyl acetate uniformly in the reaction kettle according to the given mass, and add the catalyst p-toluenesulfonic acid (0.4% of the mass of the anhydride) to react for 3 hours at 115°C under nitrogen protection; continue Add a given mass of phthalic anhydride and react for 2 hours; add epichlorohydrin, and add catalyst cetyl ammonium bromide (0.5% of the epoxy compound mass fraction) and ethyl acetate to react for 5 hours at 130°C under nitrogen protection to acid The value is less than 10mgKOH / g, the temperature is lowered and the material is discharged to obtain a hyperbranched hydroxyl polyes...

Embodiment 3

[0065] (1) A kind of hyperbranched hydroxyl polyester resin (HBP-3), the mass percentage composition of raw material formula is as shown in Table 7 (excluding catalyst):

[0066] Table 7

[0067]

[0068] (2) The preparation technology of this hyperbranched hydroxyl polyester resin (HBP-3), comprises the following steps:

[0069] Mix 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, ditrimethylolpropane, and propylene glycol methyl ether acetate in a given mass evenly in the reactor, and add the catalyst p-toluenesulfonic acid ( 0.1% of acid anhydride quality) reacted 3h under 105 ℃ of nitrogen protection; Continue to add the phthalic anhydride of given quality, react 2h; Add E10P, and add catalyst tetraethylammonium bromide (1.2% of epoxide mass fraction) and propylene glycol Methyl ether acetate was reacted at 120°C under nitrogen protection for 5 hours until the acid value was less than 10mgKOH / g, and the temperature was lowered to discharge to obtain hyperbranched ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com