Ternary catalysis system used for selective hydrogenation of conjugated diene containing polymer and application thereof

A technology of conjugated diolefins and catalytic systems, applied in organic compound/hydride/coordination complex catalysts, catalytic reactions, physical/chemical process catalysts, etc., can solve problems such as large temperature fluctuations and difficult reaction control, Achieve the effects of improving hydrogenation efficiency, stable hydrogenation activity, and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

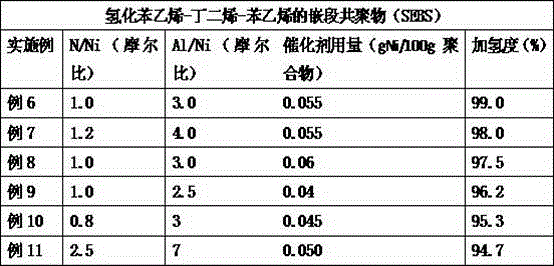

[0024] Add 45 mL of 3 g / L nickel naphthenate solution in cyclohexane (0.0023 mol in terms of Ni molar content) to the three-necked flask replaced by high-purity nitrogen, and add 0.108 g of tetramethylethylenediamine (calculated in terms of N molar content as 0.0018mol), react at 55°C for 15min to form a complex, then add 1.36g of triisobutylaluminum (0.0069mol in terms of Al molar content), age at 60°C for 30min, then add to 300g of SEPS base glue In the process, react for 120min under a hydrogen pressure of 2.5MPa, and the reaction temperature fluctuates in the range of 65-90°C. The hydrogenated glue solution is released from the bottom of the hydrogenation kettle and the hydrogenation degree is 99.5% by iodometric method.

Embodiment 2

[0026] Add 45mL of 3g / L nickel naphthenate cyclohexane solution (0.0023mol in terms of Ni molar content) into the three-necked flask replaced by high-purity nitrogen, and add 0.135g of tetramethylethylenediamine (calculated in N molar content 0.0023mol), reacted at 55°C for 15min to form a complex, then added 1.36g of triisobutylaluminum (0.0069mol in terms of Al molar content), aged at 60°C for 30min and added to 300g of SEPS base rubber In the liquid, react under a hydrogen pressure of 2.5MPa for 120min, and the reaction temperature fluctuates in the range of 65-90°C. The hydrogenated glue solution is released from the bottom of the hydrogenation kettle, and the hydrogenation degree is 98.7% by iodometric method.

Embodiment 3

[0028] Add 45 mL of 3 g / L nickel naphthenate solution in cyclohexane (0.0023 mol in terms of Ni mole content) to the three-necked flask replaced by high-purity nitrogen, and add 0.108 g of tetramethylethylenediamine (in terms of N mole content 0.0018mol), react at 65°C for 5min to form a complex, then add 1.81g of triisobutylaluminum (0.0092mol in terms of Al molar content), age at 60°C for 30min, then add to 300g of SEPS base rubber In the liquid, react under the hydrogen pressure of 2.5MPa for 120min, and the reaction temperature fluctuates in the range of 65-90°C. The hydrogenated glue solution is released from the bottom of the hydrogenation kettle, and the hydrogenation degree is 97.5% by iodometric method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com