Selective hydrogenation catalyst, preparation method and application thereof

A technology for selective hydrogenation and catalysts, applied in the direction of selective hydrogenation refining, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems to be further improved, and achieve low-temperature hydrogenation High activity, stable hydrogenation activity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] step 1:

[0037] (1) 1.5molAl (NO 3 ) 3 9H 2 O crystals were added to the corresponding volume of deionized water to make them fully dissolved and prepared into a 1.55mol / L aluminum salt solution (A).

[0038] (3) 0.025mol Mg (NO 3 ) 2 ·6H 2 O crystals were added to the corresponding volume of deionized water to make it fully dissolved and prepared into a 0.025mol / L solution (B),

[0039] (4) Calculate the amount of the corresponding (A) and (B) solutions according to the mass percentage of the component MgO as 1%, and mix them uniformly to obtain the mixed solution (C) containing Mg and Al

[0040] (5) Using co-current co-precipitation method, add (NH 4 ) 2 CO 3 solution or ammonia solution and the prepared mixed solution (C) containing Mg and Al, the dropping rate of the mixed solution (C) is 30 drops / min, (NH 4 ) 2 CO 3 Or the dropping rate of the ammonia solution is 20 drops / min; finally, adjust the pH of the precipitate to pH=8 with ammonia water, and f...

Embodiment 2

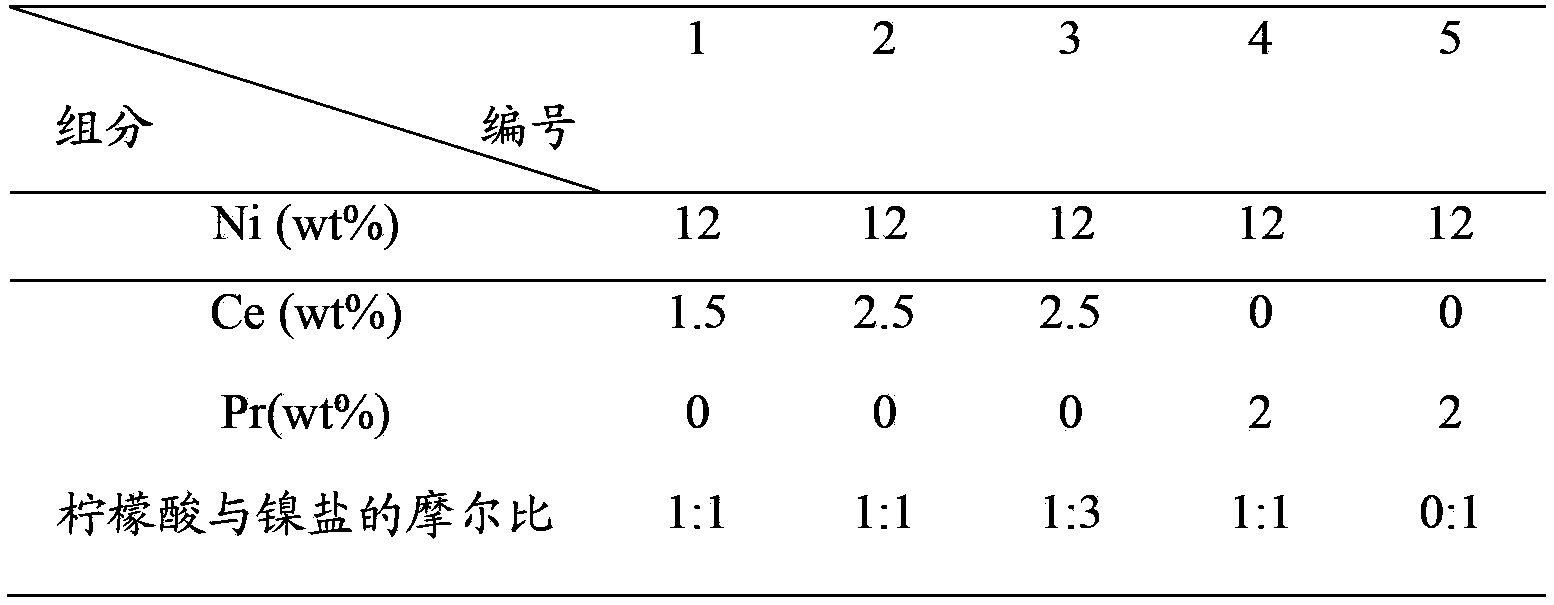

[0045] The method is the same as that in Example 1, except that the Ce weight content in the catalyst is 2.5 wt%, and Catalyst 2 is prepared. See Table 1 for details.

Embodiment 3

[0047]The method is the same as in Example 1, except that the molar ratio of metallic nickel to citric acid in the impregnating solution in step 2 is 3:1, and the Ce weight content in the catalyst is 2.5wt%, to obtain catalyst 3. See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com