A nitrogen-doped carbon-coated catalyst, its preparation method and application

A nitrogen-doped carbon and catalyst technology, which is applied in the field of halogenated nitroaromatics to prepare halogenated aromatic amines by catalytic hydrogenation, can solve the problems of ammonium shedding and affecting product quality, achieve stable hydrogenation activity, reduce process costs, The effect of chemical structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

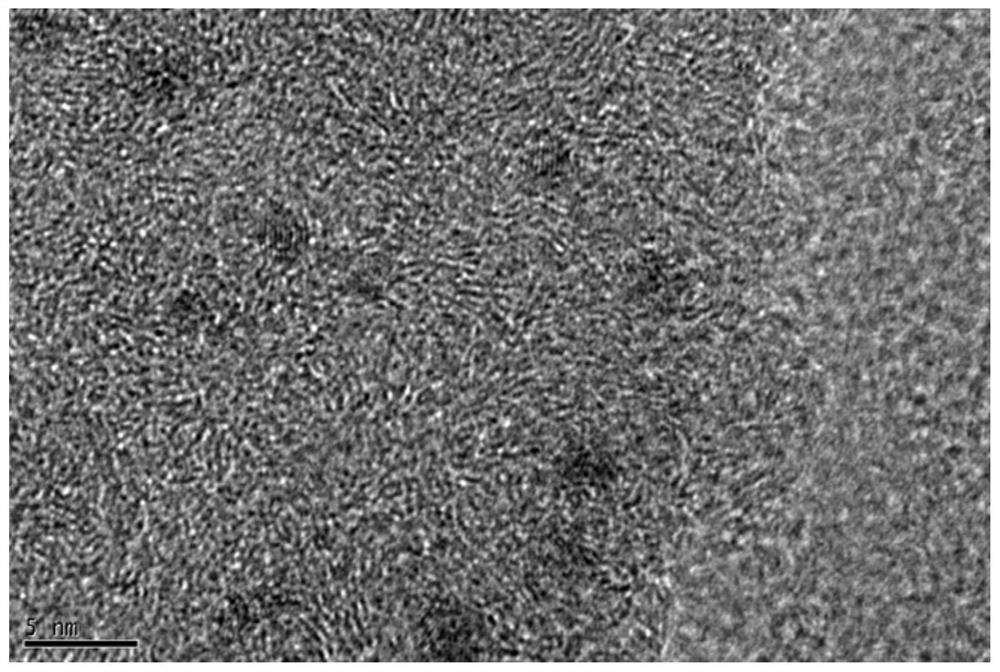

[0034] Weigh 1g of supported metal catalyst Pt / C, wherein the loading of Pt is 0.85%, according to the mass ratio of supported noble metal catalyst and nitrogen-containing compound of 1:4, weigh 4g of urea, after physical mixing, place in a 50mL crucible , placed in a muffle furnace, raised to 400°C, kept for 5h, and then lowered to room temperature to obtain nitrogen-doped carbon-coated platinum-on-carbon catalyst 1 (CN@Pt / C), wherein the thickness of nitrogen-doped carbon is 2nm.

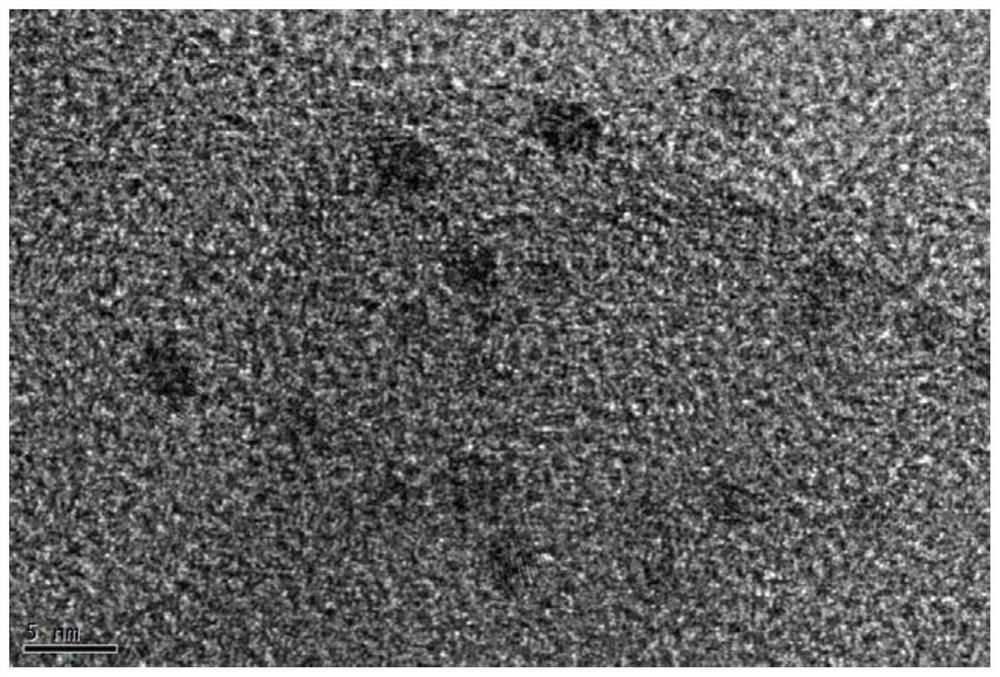

[0035] figure 1 It is the TEM picture of supported metal catalyst 0.85%Pt / C, figure 2 TEM image of nitrogen-doped carbon-coated platinum carbon catalyst 1 (CN@Pt / C) in Example 1, for comparison figure 1 and figure 2 , the nitrogen-doped carbon layer wraps the Pt metal active sites on the platinum-carbon catalyst well.

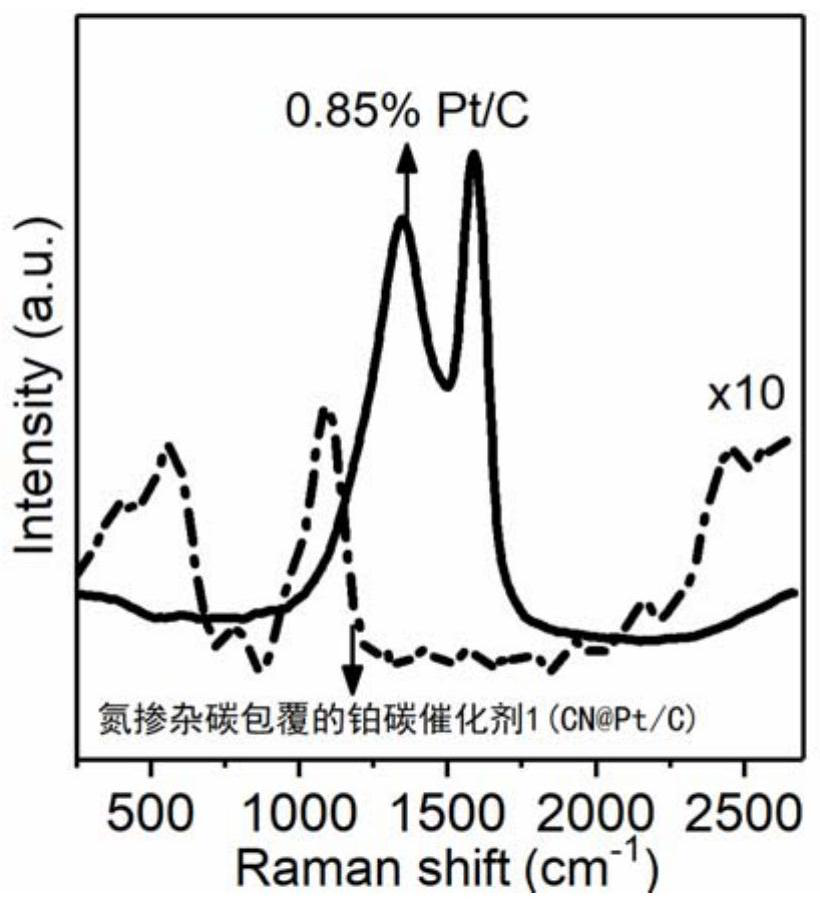

[0036] image 3 It is the supported metal catalyst 0.85%Pt / C and the Raman spectrum of nitrogen-doped carbon-coated platinum carbon catalyst 1 (CN@Pt / C) obtained in this exam...

Embodiment 2

[0041] Weigh 1g of supported metal catalyst Pt / Al 2 o 3 , wherein the loading capacity of Pt is 0.85%, according to the mass ratio of supported noble metal catalyst and nitrogen-containing compound 1:6, take by weighing 6g melamine, after physical mixing, place the crucible of 50mL, put into the muffle furnace, rise to 600°C, kept for 3h, then cooled down to room temperature, and nitrogen-doped carbon-coated platinum-on-carbon catalyst 2 (CN@Pt / Al 2 o 3 ), where the nitrogen-doped carbon has a thickness of 5 nm.

Embodiment 3

[0043] Take by weighing 1g supported metal catalyst Pt / Y type molecular sieve, wherein the loading capacity of Pt is 0.85%, according to the mass ratio 1:10 of supported noble metal catalyst and nitrogen-containing compound, take by weighing 10g dicyandiamide, after physically mixing, place In a 50mL crucible, put it into a muffle furnace, raise it to 800°C, keep it for 1h, and cool it down to room temperature to obtain nitrogen-doped carbon-coated platinum carbon catalyst 3 (CN@Pt / Y molecular sieve), in which nitrogen-doped The carbon has a thickness of 10 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com