Preparation method of Brassica rapa powder

A technology of Qiama ancient powder and Qiama ancient, which is applied in the field of preparation of Qiama ancient powder, which can solve the problems of unfavorable microbial production, difficulty in storage and inedibility of fresh Qiama ancient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

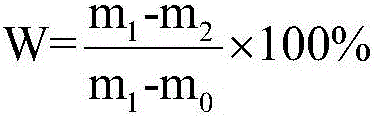

[0014] Embodiment 1, the preparation method of the Qiama ancient powder is carried out according to the following steps: the first step is to cut the fresh Qiama ancient into pieces, the solid-liquid ratio of the Qiama ancient pieces to water is 1:1 to 1:5, Put it into a tissue masher for beating to obtain Qiama ancient pulp; in the second step, pour the Qiama ancient pulp into the colloid mill to obtain the old Qiama pulp after the rubber mill; in the third step, after the glue mill Adding an anti-caking agent to the Qiama ancient pulp to obtain the anti-caking Qiama ancient pulp; the fourth step, homogenizing the anti-caking Qiama ancient pulp in a homogenizer to obtain homogeneous Qiama ancient pulp; the fifth step , spray-drying the homogeneous Qiama ancient pulp until the water content is not more than 5%, and obtain Qiama ancient powder. The Qiama ancient powder obtained by using the method is light yellow in color, uniform in particle size, free from agglomeration, rich...

Embodiment 2

[0015] Embodiment 2, the preparation method of the Qiama ancient powder, according to the following steps: the first step, the fresh Qiama ancient cut into pieces, the solid-liquid ratio of Qiama ancient block and water is 1:1 or 1:5, Put it into a tissue masher for beating to obtain Qiama ancient pulp; in the second step, pour the Qiama ancient pulp into the colloid mill to obtain the old Qiama pulp after the rubber mill; in the third step, after the glue mill Adding an anti-caking agent to the Qiama ancient pulp to obtain the anti-caking Qiama ancient pulp; the fourth step, homogenizing the anti-caking Qiama ancient pulp in a homogenizer to obtain homogeneous Qiama ancient pulp; the fifth step , spray-drying the homogeneous Qiama ancient pulp until the water content is not more than 5%, and obtain Qiama ancient powder.

Embodiment 3

[0016] Embodiment 3, as an optimization of the above embodiment, the beating time in the first step is 10 minutes to 20 minutes; or / and, the time for rubber grinding in the second step is 10 minutes to 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com