A high-efficiency improver for anti-sludge cake

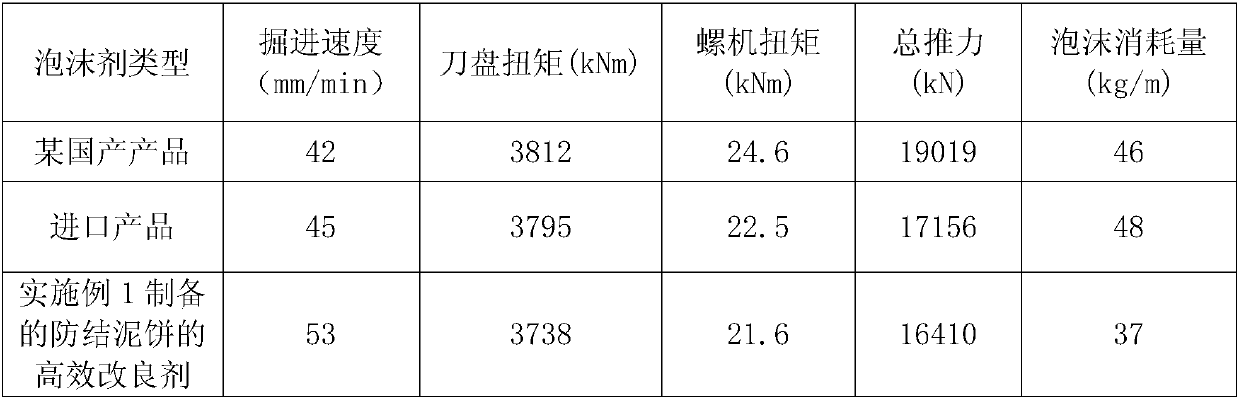

The technology of modifier and mud cake is applied in the field of high-efficiency modifier for preventing mud cake, which can solve the problems such as the performance decline of the rubber seal of the rotary center, the increased load of the shield cutter head and the cutter, and the poor improvement effect of the viscous soil layer, etc. Achieve fast and sufficient wettability and dispersion, improve shield tunneling speed, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

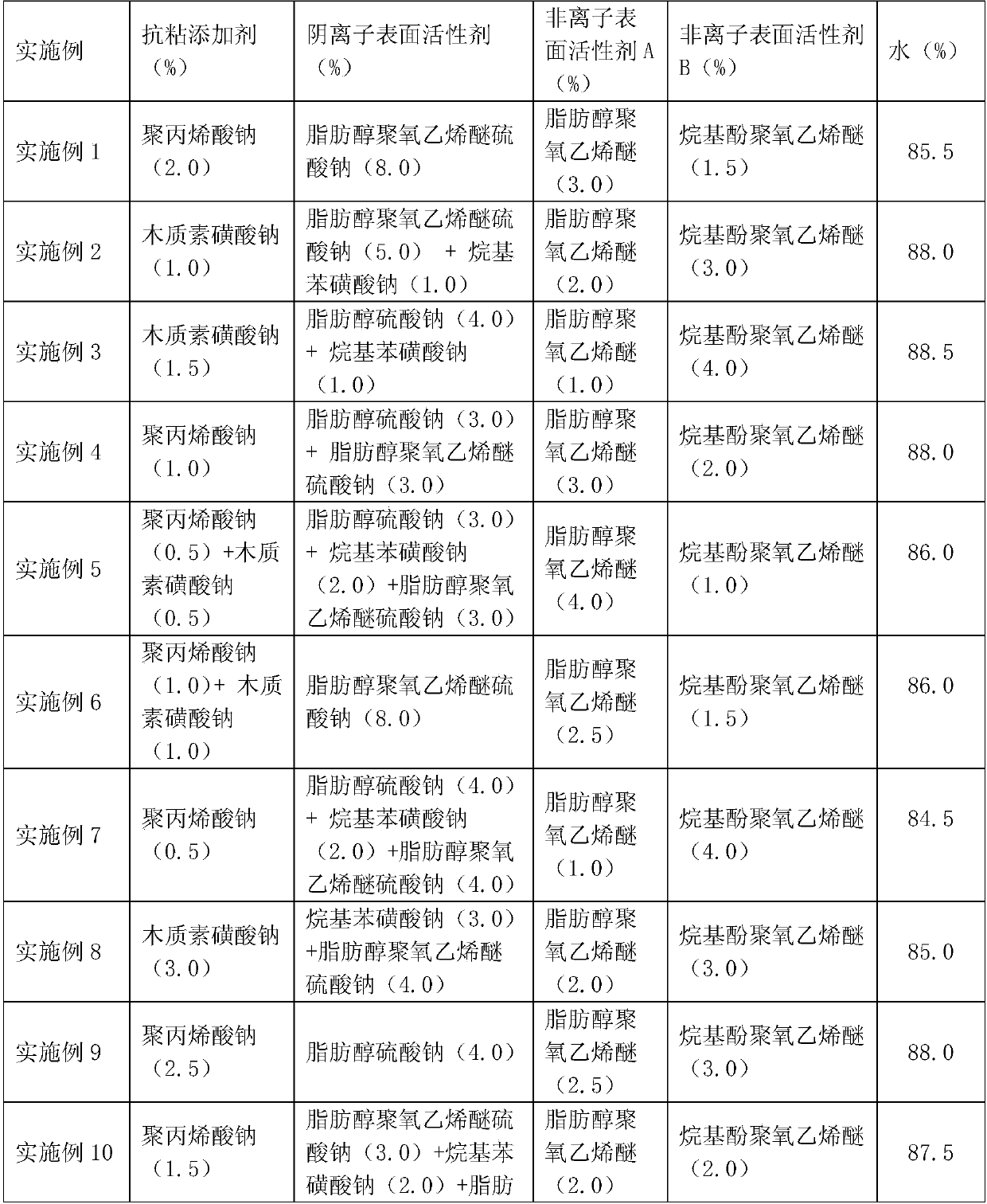

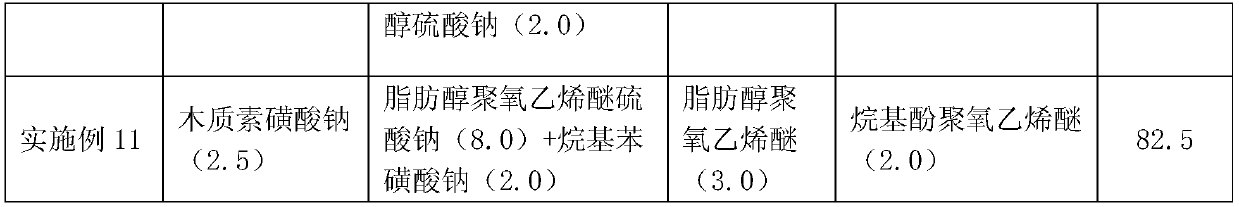

[0013] A high-efficiency improver for anti-sludge cake of the present invention is made from the following raw materials in mass content: 0.5-3.0% of anti-adhesive additive, 4.0-10.0% of anionic surfactant, 1.0-4.0% of non-ionic surfactant A and 1.0-4.0% of non-ionic surfactant B, the balance is water, and the total mass is 100%; the anti-adhesive additive is one or a mixture of sodium polyacrylate and sodium lignosulfonate. Preferably, the anti-adhesive additive is 1.0-2.0%, the anionic surfactant is 6.0-8.0%, the non-ionic surfactant A is 2.0-3.0% and the non-ionic surfactant B is 1.5-3.0%. The molecular weight of sodium polyacrylate is 2000-10000.

[0014] Wherein, the anionic surfactant is a mixture of fatty alcohol polyoxyethylene ether sodium sulfate and fatty alcohol sodium sulfate; or one or both of fatty alcohol polyoxyethylene ether sodium sulfate and fatty alcohol sodium sulfate Mixture of both with sodium alkylbenzene sulfonate. Preferably, the anionic surfactant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com