Aerogel-metal composite material, and preparation method and application thereof

A metal composite material and airgel technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of lack of depth in the comprehensive utilization of airgel, and achieve the effects of high strength, convenient operation, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

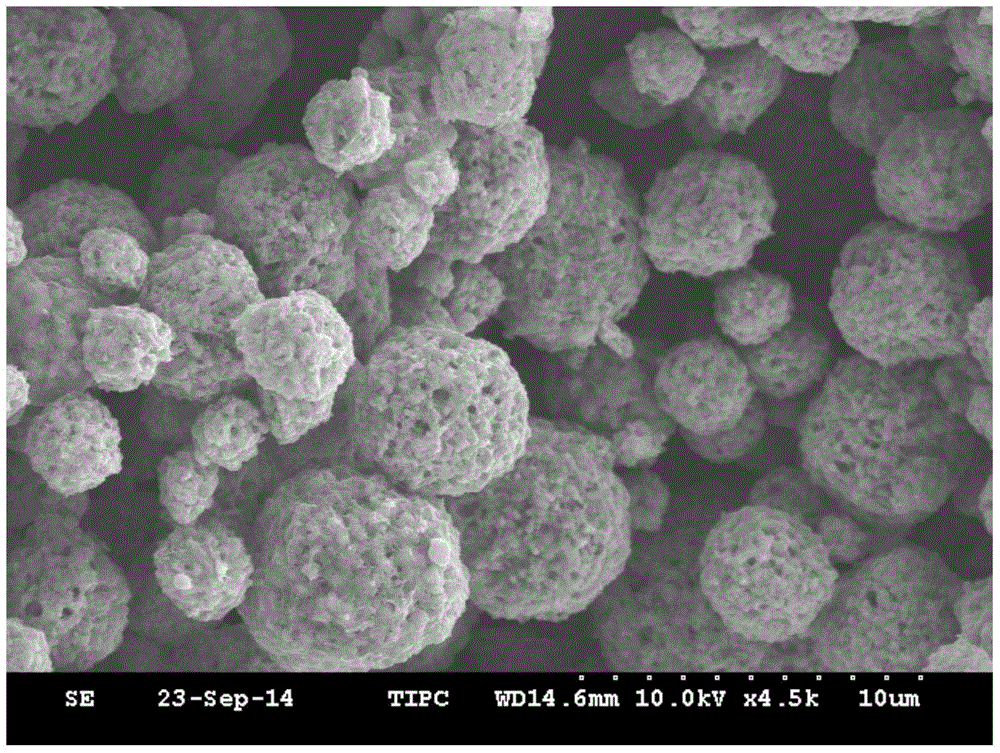

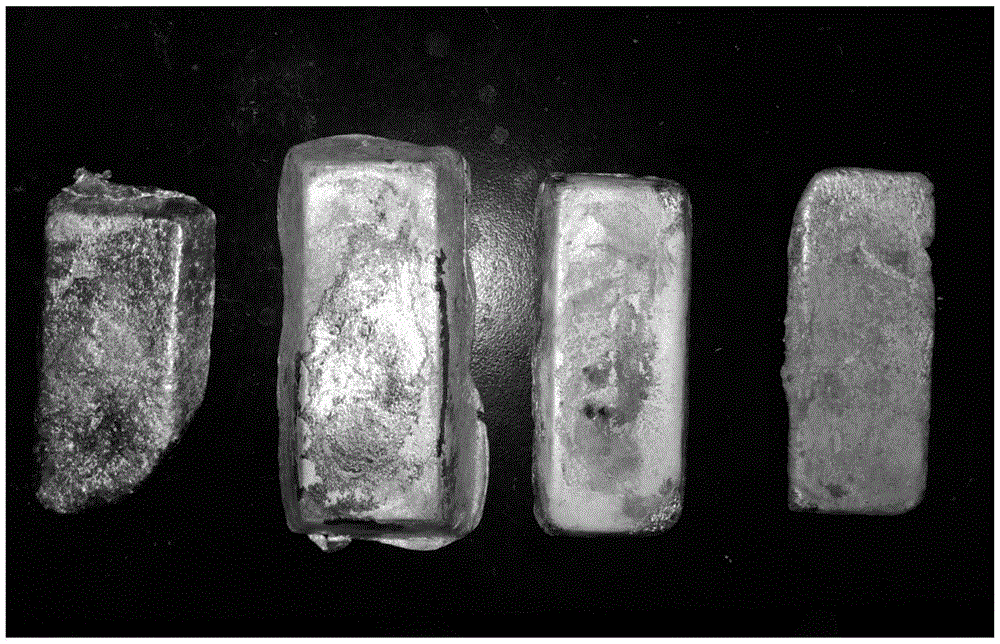

Embodiment 1

[0034] Set the density to 0.01g / cm 3Add the silica airgel into a high-speed pulverizer, and pulverize at a speed of 2000-50000r / min for 1-200min to obtain silica airgel powder. Pass the above powder through 100-mesh, 1000-mesh, and 2500-mesh sieves in sequence to obtain an airgel powder with a particle size of about 5 μm. The above-mentioned silica airgel powder and aluminum powder are mixed uniformly in a certain ratio, and the volume ratio of the airgel powder to the aluminum powder is 1:1 to 1:25. The particle size of the aluminum powder used is 300 mesh. The mixture of the above-mentioned airgel and aluminum powder is placed in a closed container, and heated from room temperature to 660-800°C under the protection of nitrogen, with a heating rate of 5-200°C / min. After the aluminum is melted, stir with a certain intensity to further mix the system evenly. The holding time is 0-4 hours. After skimming off impurities such as oxidized slag in the upper layer, transfer the m...

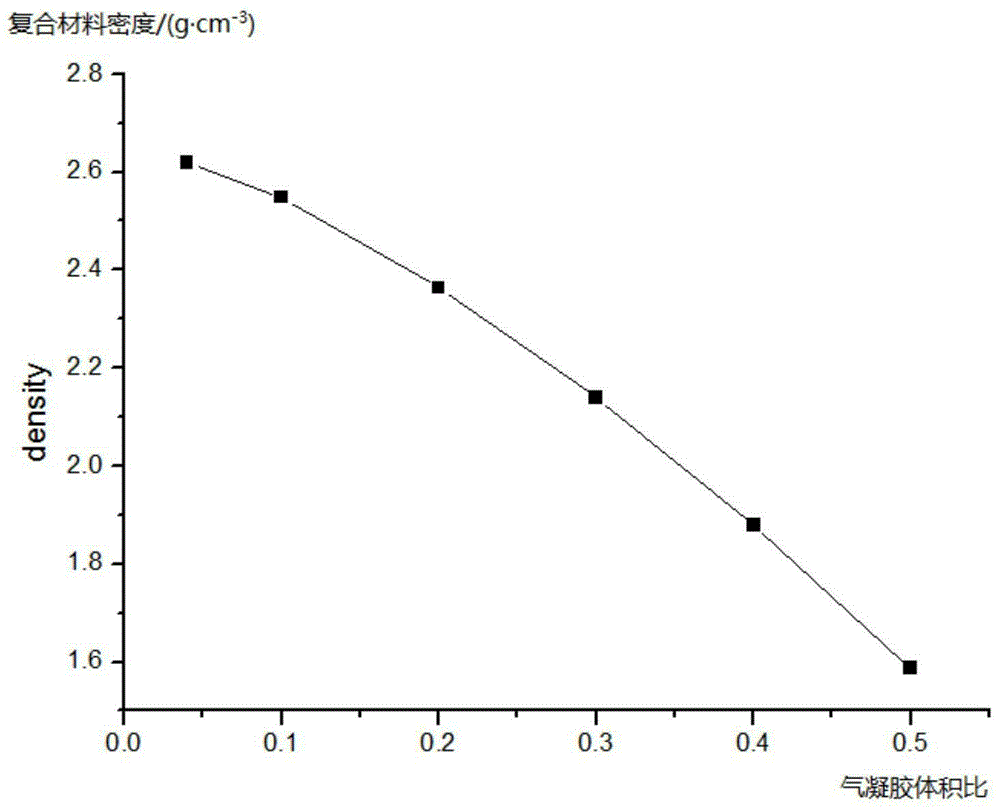

Embodiment 2

[0036] According to the method described in Example 1, a uniform silica airgel powder with a particle size of about 5 μm was prepared. Melting aluminum particles with a certain particle size under the protection of nitrogen, the particle size of the aluminum particles used is 0.1-20mm, and the heating rate is 5-200°C / min. After the aluminum particles are completely melted, add the above-mentioned airgel powder. The volume ratio of the airgel powder to the aluminum liquid is 1:1 to 1:25. Stir with a certain intensity to make the system evenly mixed. By adopting the cooling molding and demoulding methods described in Example 1, the silica airgel-aluminum porous composite material with a certain shape can be obtained, and the density of the gained composite material is 1.82-2.64g / cm 3 .

Embodiment 3

[0038] According to the method described in embodiment 1, the density is 0.030g / cm 3 The alumina airgel was pulverized and sieved to obtain uniform alumina airgel powder. The above-mentioned alumina airgel powder and copper powder are mixed evenly in a certain ratio, and the volume ratio of the airgel powder and copper powder is 1:1 to 1:25. The particle size of the copper powder used is preferably 300 mesh to 10 mesh. The mixture of the above-mentioned airgel and copper powder is placed in a closed container, and heated from room temperature to 1100-1300° C. under the protection of argon, with a heating rate of 5-200° C. / min. After the copper is melted, stir with a certain intensity to further mix the system evenly. The holding time is 0-4 hours. After skimming off impurities such as oxidized slag on the upper layer, transfer the mixture of copper liquid and alumina airgel into a mold, and cool and form at a cooling temperature of 5-100°C / min. After the mixture is cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com