A kind of high-performance anti-tracking addition type liquid silicone rubber and its preparation method

A liquid silicone rubber and tracking technology, which is applied in the field of rubber insulating materials and silicone rubber insulating materials, can solve the problems of easy volatilization, harm to human body and environment, and increase the cost of industrial application, so as to achieve easy industrial production, wide application prospects, The effect of reducing the synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

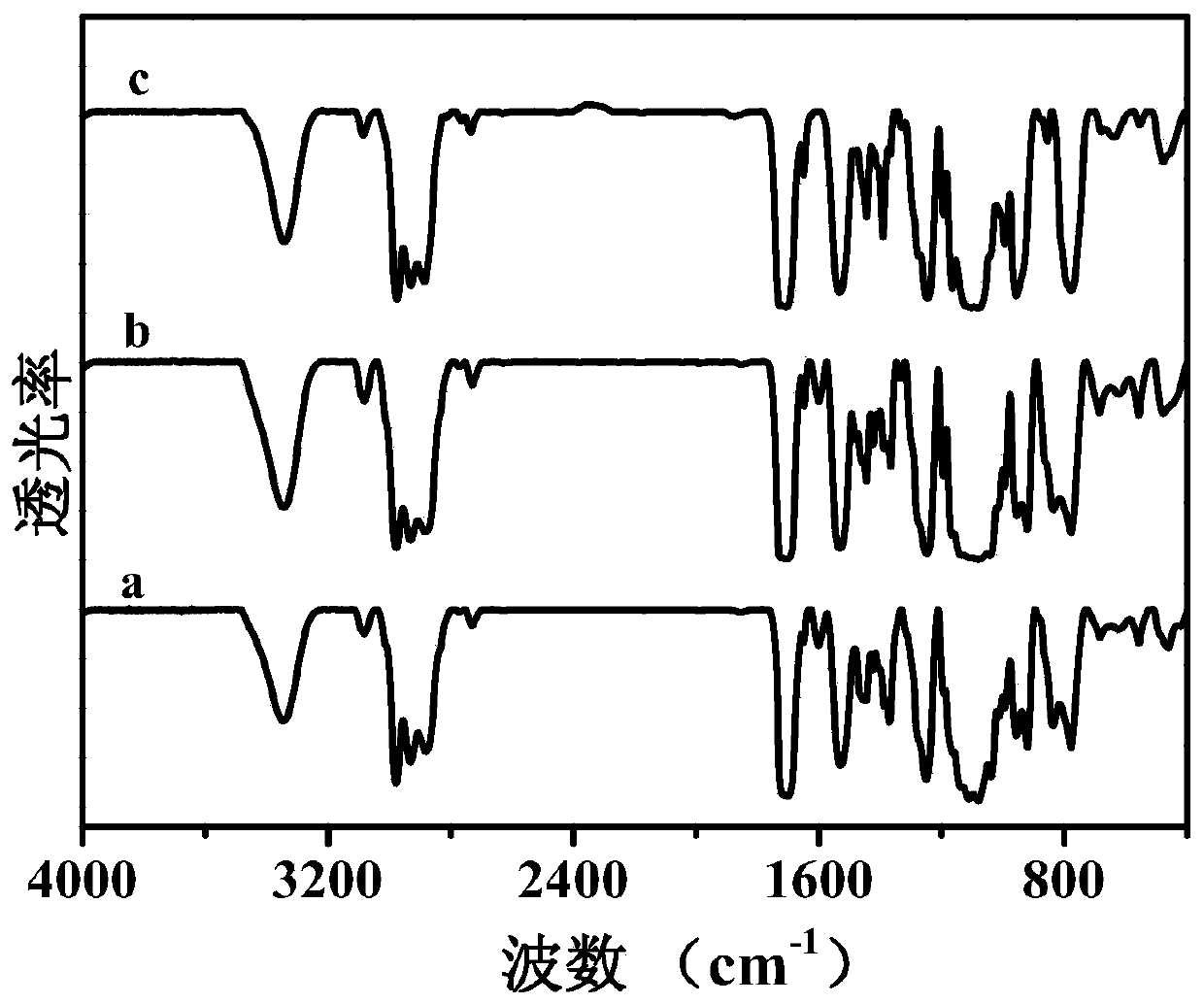

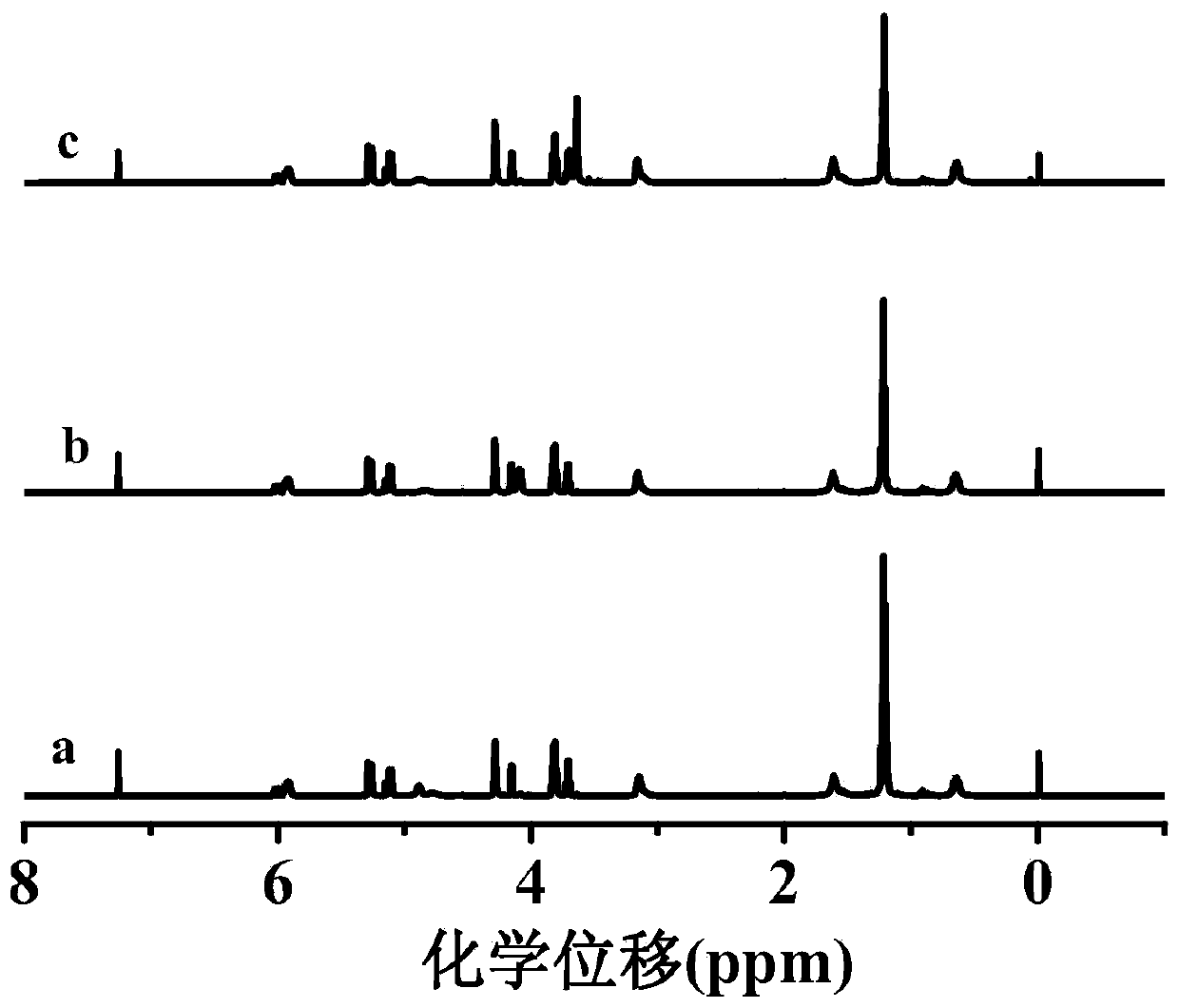

Image

Examples

Embodiment 1

[0039] Add 13.2g of isopropanol, 49.4g of 3-isocyanatopropyl triethoxysilane and 0.18g of dibutyltin dilaurate into a 250mL four-neck flask equipped with a reflux condenser, mechanical stirring and a thermometer. The reaction was stirred for 3 h, and then the unreacted isopropanol was distilled off under reduced pressure to obtain 3-(isopropyl carbamate)propyltriethoxysilane (IPURPES).

[0040] Add 23.5g allyl alcohol, 43.1g 3-(isopropyl carbamate) propyltriethoxysilane and 0.66g methyl titanate into a 250mL four-necked flask equipped with a reflux condenser, mechanical stirring and a thermometer , stir evenly at room temperature, heat up to 80° C. for reflux reaction for 2 h, and finally remove low boilers by distillation under reduced pressure to obtain the product 3-(isopropyl carbamate) propyl triallyloxysilane (IPURPAS).

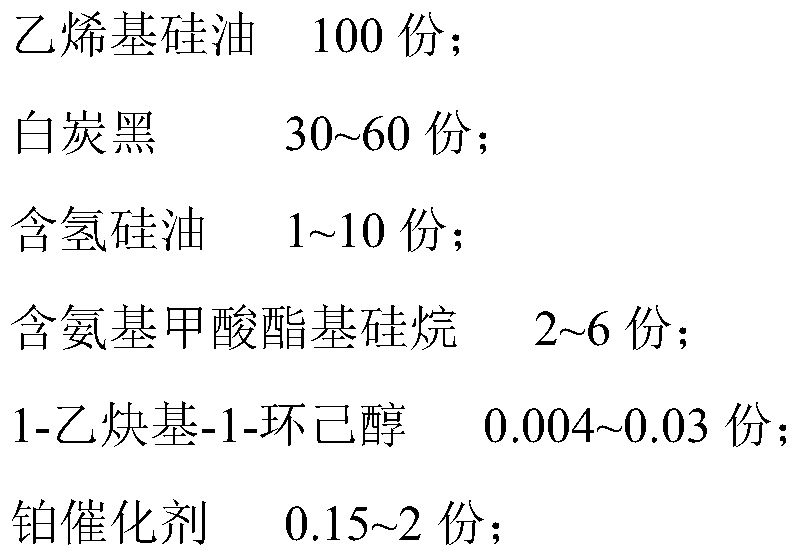

[0041] 100 parts by mass of vinyl silicone oil (viscosity at 25°C is 25200mPa·s, vinyl content is 0.25mol%), 40 parts by mass of fumed silica (specific...

Embodiment 2

[0044] Add 11.0 g of ethanol, 49.4 g of 3-isocyanatopropyltriethoxysilane and 0.06 g of stannous octoate into a 250 mL four-neck flask equipped with a reflux condenser, mechanical stirring and a thermometer, and stir the reaction at 30 ° C for 4 h. Then unreacted ethanol was distilled off under reduced pressure to obtain 3-(ethylcarbamate)propyltriethoxysilane (EURPES).

[0045] 7.9g allyl alcohol, 41.1g 3-(urethane) propyltriethoxysilane and 0.98g butyl titanate were added to a 250mL four-necked flask equipped with a reflux condenser, mechanical stirring and a thermometer, Stir evenly at room temperature, raise the temperature to 70° C. for reflux reaction for 3 h, and finally remove low boilers by distillation under reduced pressure to obtain the product 3-(urethane)propylallyloxydiethoxysilane (EURPAS).

[0046] The IPURPAS of 1 in the embodiment is changed into EPURPAS, and the consumption is increased to 6 mass parts, and the corresponding hydrogen-containing silicone oil...

Embodiment 3

[0048] Add 8.3g of methanol, 41.0g of 3-isocyanatopropyltrimethoxysilane and 0.03g of dibutyltin dilaurate into a 250mL four-necked flask equipped with a reflux condenser, mechanical stirring and a thermometer, and stir the reaction at 40°C for 1h , and then distilled off unreacted methanol under reduced pressure to obtain 3-(methyl carbamate)propyltrimethoxysilane (MURPMS).

[0049] 23.5g allyl alcohol, 33.3g 3-(methyl carbamate) propyltrimethoxysilane and 0.06g isopropyl titanate were added to a 250mL four-necked flask equipped with a reflux condenser, mechanical stirring and a thermometer, Stir evenly at room temperature, raise the temperature to 90° C. for reflux reaction for 6 h, and finally remove low boilers by distillation under reduced pressure to obtain the product 3-(methyl carbamate)propyltriallyloxysilane (MURPAS).

[0050] The IPURPAS of 1 in the embodiment is changed to MPURPAS, the consumption is 2 mass parts, and the corresponding hydrogen-containing silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com