A kind of halogen-free flame-retardant reinforced addition type liquid silicone rubber and preparation method thereof

A technology of liquid silicone rubber and addition molding, which is applied in the field of flame retardancy of organic silicon polymer materials, can solve the problems of deteriorating the processing performance and mechanical properties of the liquid silicone rubber of the addition molding, and achieves good processing performance, little influence, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

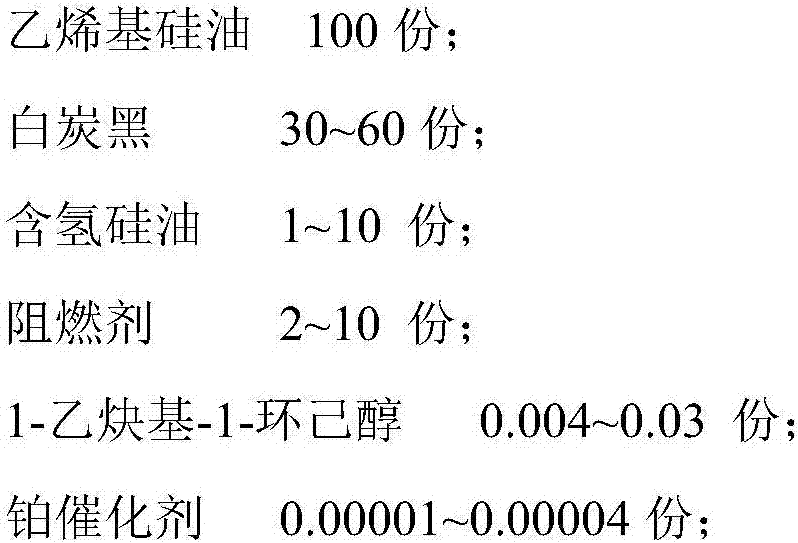

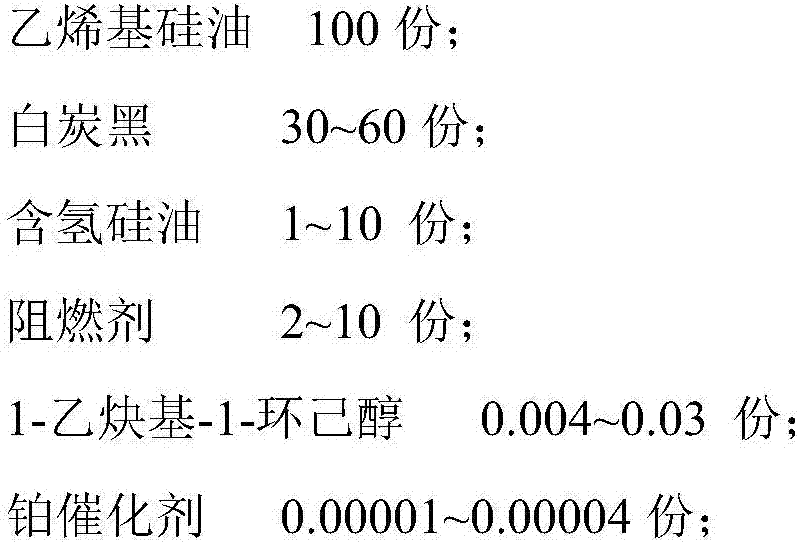

[0036] Add 6 g of zirconium hydrogen phosphate (ZrP) into 600 g of toluene, ultrasonically disperse for 0.1 h, add hindered amine 1 (the molar ratio of zirconium hydrogen phosphate to hindered amine 1 is 1:2), ultrasonicate for 0.5 h, and stir at 30°C for 3 h , washed, centrifuged, and dried to obtain hindered amine intercalation modified zirconium hydrogen phosphate (M-ZrP), the structural formula of hindered amine 1 is shown below.

[0037]

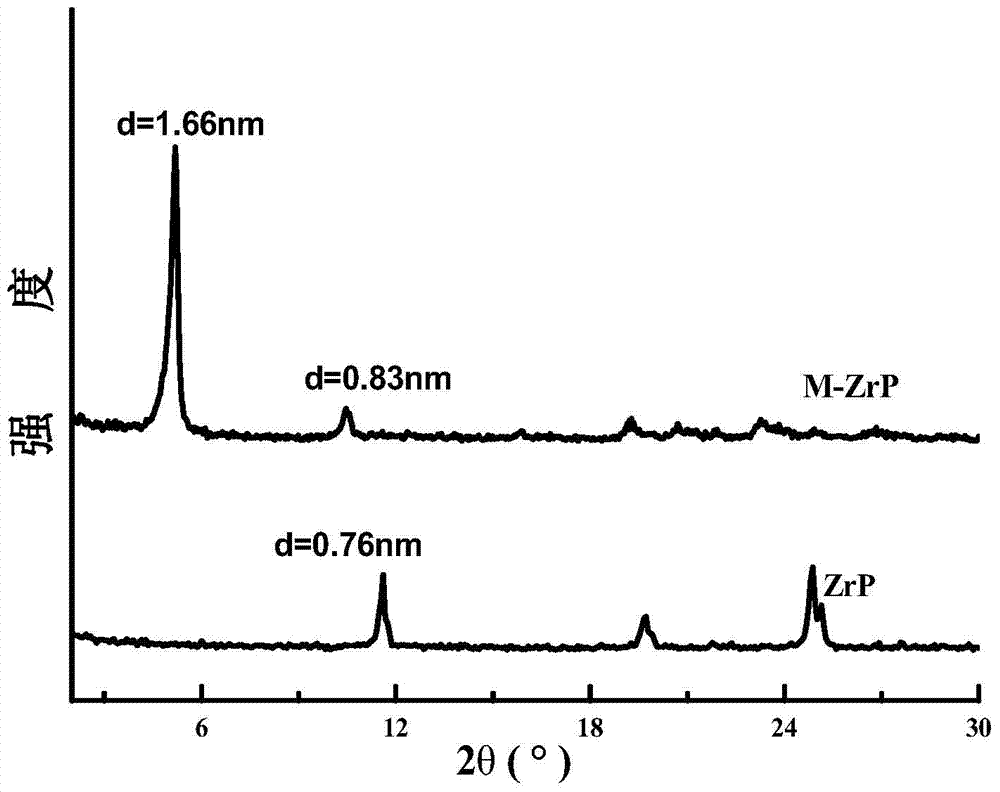

[0038] By the XRD spectrum of ZrP and M-ZrP ( figure 1 ) shows that the interlayer spacing of HA1 intercalation modified zirconium hydrogen phosphate (M-ZrP) increased from 0.76nm (2θ=11.64°) of ZrP to 1.66nm (2θ=5.26°), indicating that HA1 was successfully inserted into ZrP interlayer. 91g of vinyl silicone oil (viscosity at 25°C of 20000mPa·s, vinyl content of 0.12wt%), 40g of fumed silica (specific surface area of 360m 2 / g) mixed in a vacuum kneader, kneaded at 30°C for 2h, heated to a material temperature of 170°C and contin...

Embodiment 2

[0043] Add 6 g of zirconium hydrogen phosphate (ZrP) into 180 g of acetone, ultrasonically disperse for 0.1 h, add hindered amine 2 (the molar ratio of zirconium hydrogen phosphate to hindered amine 2 is 1:2), sonicate for 2 h, and stir at 30°C for 6 h, Washing, centrifugation, and drying obtained hindered amine intercalation modified zirconium hydrogen phosphate (M-ZrP). The structural formula of hindered amine 2 is shown below. XRD results showed that hindered amine 2 was successfully inserted into the interlayer of zirconium hydrogen phosphate.

[0044]

[0045] 91g of vinyl silicone oil (viscosity at 25°C of 20000mPa·s, vinyl content of 0.12wt%), 40g of fumed silica (specific surface area of 360m 2 / g) mixed in a vacuum kneader, kneaded at 30°C for 2h, heated to a material temperature of 170°C and continued kneading for 2h, then evacuated and kneaded for 1h, cooled and ground by a three-roll machine to obtain component A.

[0046] Add 4.5g of M-ZrP into 135g of dimeth...

Embodiment 3

[0050] Add 6 g of zirconium hydrogen phosphate (ZrP) into 300 g of ethanol, ultrasonically disperse for 0.1 h, add hindered amine 3 (the molar ratio of zirconium hydrogen phosphate to hindered amine 3 is 1:2), sonicate for 1 h, and stir at 30°C for 6 h, Washing, centrifugation, and drying obtained hindered amine intercalation modified zirconium hydrogen phosphate (M-ZrP). The structural formula of hindered amine 3 is shown below. XRD results showed that hindered amine 3 was successfully intercalated between zirconium hydrogen phosphate layers.

[0051]

[0052] 91g of vinyl silicone oil (viscosity at 25°C of 20000mPa·s, vinyl content of 0.12wt%), 40g of fumed silica (specific surface area of 360m 2 / g) mixed in a vacuum kneader, kneaded at 30°C for 2h, heated to a material temperature of 170°C and continued kneading for 2h, then evacuated and kneaded for 1h, cooled and ground by a three-roll machine to obtain component A.

[0053] Add 4.5g of M-ZrP to 450g of carbon tetra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com