A kind of high damping rubber material and preparation method thereof

A rubber material and high damping technology, which is applied in the field of rubber modification, can solve the problems of the migration of small molecules of the second component, the deterioration of physical and mechanical properties, and the decrease of rubber elasticity, so as to achieve low cost, increase modulus, and improve damping performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

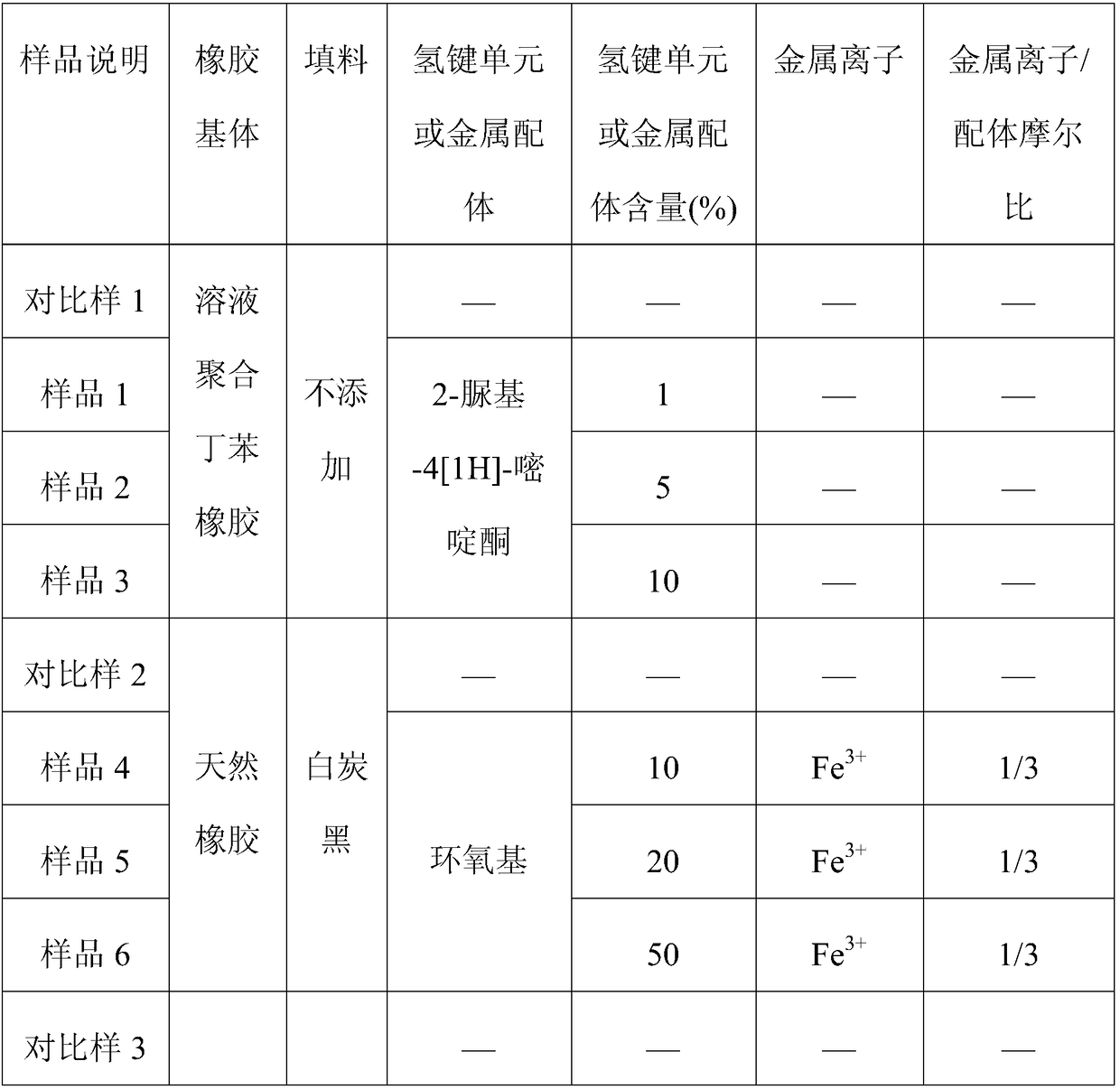

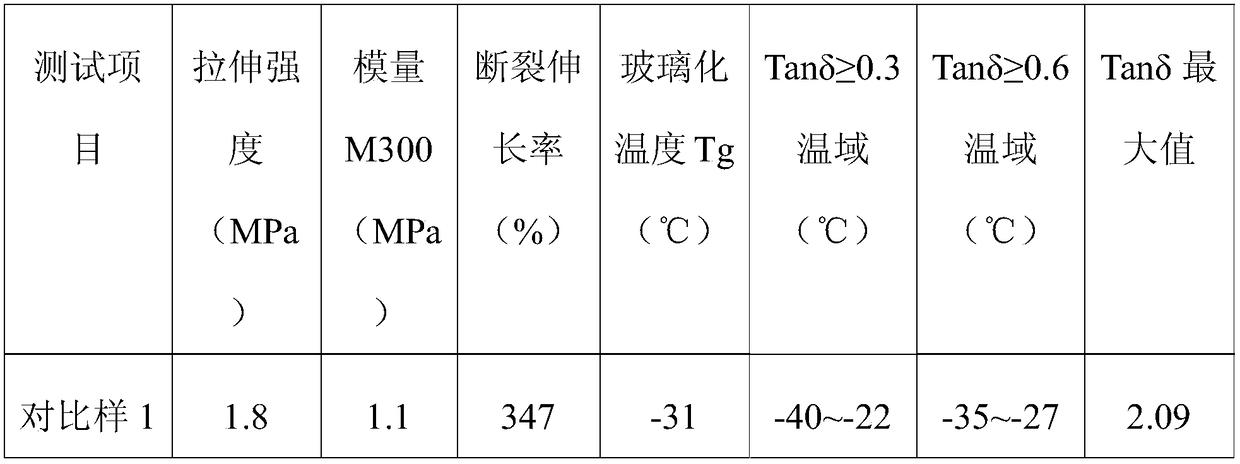

Embodiment 1

[0033] (1) Taking solution polymerization styrene-butadiene rubber as the matrix, using azobisisobutyronitrile as the initiator, grafting mercaptoethanol to the solution polymerization styrene-butadiene rubber through mercapto-vinyl click chemical reaction; then using hydroxyl and 2-( 6-isocyanatocarbonylamino)-6-methyl-4-[1H]pyrimidinone reacts to introduce 2-ureido-4[1H]-pyrimidinone quadruple hydrogen bond units into the rubber molecular chain, the quadruple The content of hydrogen bond units is 1%, 5% and 10% of the number of moles of double bonds in the rubber; the solution-polymerized styrene-butadiene rubber containing quadruple hydrogen bond units is mixed with a vulcanization bag by a double-roll mill to obtain a mixed rubber Use a flat vulcanizer to mold at 150°C according to the positive vulcanization time to obtain sample 1, sample 2 and sample 3;

[0034] (2) Using solution-polymerized styrene-butadiene rubber as a matrix, a double-roll mill was used to mix it wit...

Embodiment 2

[0037] (1) take natural rubber as matrix, m-chloroperoxybenzoic acid is oxygenant, and the epoxy natural rubber that preparation epoxidation degree is 10%, 20% and 50%; Filler silica and vulcanization bag were mixed, and the obtained mixed rubber was molded with a flat vulcanizer at 143°C according to the normal vulcanization time to obtain sample 4, sample 5 and sample 6;

[0038] (2) Using natural rubber as the matrix, using a double-roller mill to mix filler silica and vulcanization bags, the obtained mixed rubber was molded with a flat vulcanizer at 143° C. according to the positive vulcanization time to obtain Comparative Sample 2;

[0039] The content of each component is: rubber matrix 100phr, white carbon black 40phr; vulcanization package: zinc oxide 4phr, stearic acid 2phr, accelerator TT 1.2phr, accelerator NS 0.8phr, sulfur 2.0phr, ferric chloride and epoxy The group molar ratio is 1:3.

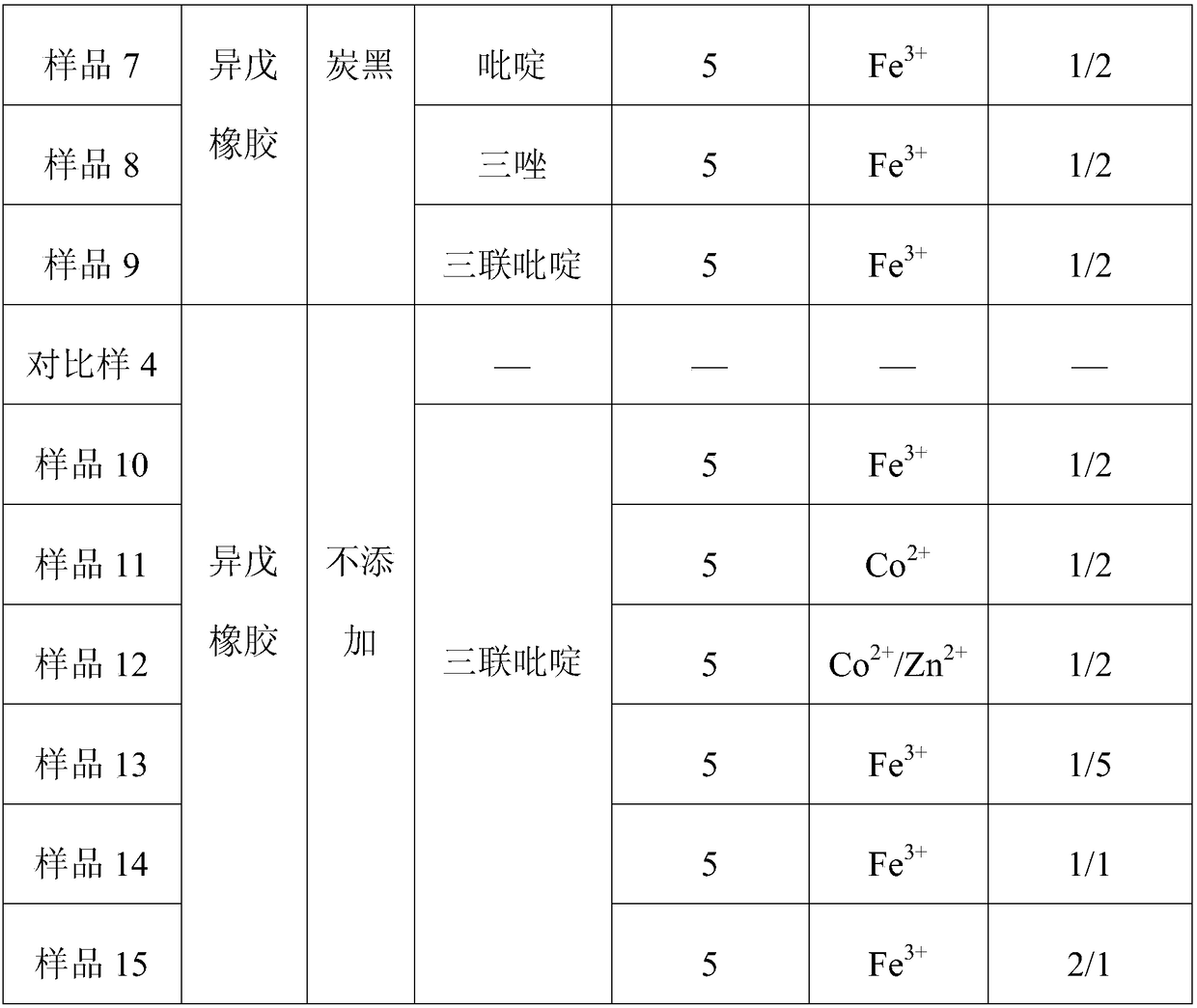

Embodiment 3

[0041] (1) With isoprene rubber as the matrix, diisophenylpropylene peroxide as the initiator, the isoprene rubber grafted with maleic anhydride is obtained by free radical grafting reaction; then by amidation reaction, the amino-containing pyridine , triazole, and terpyridine metal ligands are introduced into the rubber molecular chain, and the metal ligand content is 5% of the double bond mole number in the rubber; Black and vulcanization bags were mixed, and the obtained mixed rubber was molded with a flat vulcanizer at 143°C according to the normal vulcanization time to obtain samples 7, 8 and 9;

[0042] (2) Using isoprene rubber as the matrix, using a double-roll mill to mix filler carbon black and vulcanization bags, the obtained mixed rubber was molded with a flat vulcanizer at 143° C. according to the normal vulcanization time to obtain Comparative Sample 3;

[0043] The content of each component is: rubber matrix 100phr, carbon black 50phr; vulcanization package: zinc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com