A kind of lightweight epoxy resin microcellular foam material and preparation method thereof

A technology of microcellular foaming material and epoxy resin, applied in the field of lightweight epoxy resin microcellular foaming material and its preparation, can solve the problem of poor fluidity of prepolymer, single chemical foaming agent, high apparent density, etc. problem, to achieve the effect of uniform cell size distribution, small average cell diameter, and inhibition of merging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 100 grams of epoxy resin, 85 grams of curing agent, 0.5 grams of curing aid, 5 grams of nano silica, 2 grams of diepoxypentyl ether dioxide, added to the reactor to react until the system becomes a solid state at room temperature, after cooling , Take 100 grams of solid and 0.5 grams of N,N'-dinitrosopentamethylenetetramine and grind them into powder, then put the powder into a pre-heated mold and foam at 110°C. After 3 hours, Raise the temperature of the oven to 150°C, keep it for 3 hours and then cool down to room temperature for demoulding. Repeat the above steps, the average particle size of the ground powder is 200μm, 100μm and 30μm. Take the powder and put it in a mold, and foam it at different temperatures to obtain microcellular foam materials with different densities. Adding different content of foaming agent to the powder can also obtain epoxy resin microporous materials with different foaming densities.

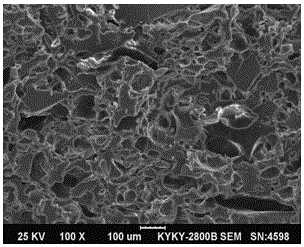

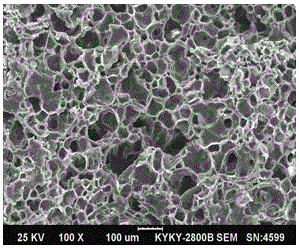

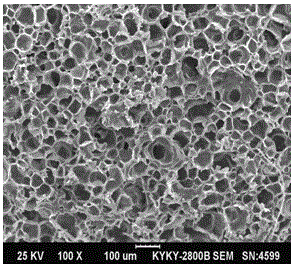

[0025] Experimental results: such as Figure 1~Figure 3...

Embodiment 2

[0027] 100 grams of epoxy resin, 80 grams of curing agent, 0.5 grams of curing aid, 5 grams of nano-calcium carbonate, 3 grams of polyethylene glycol, add to the reactor and react until the system becomes a solid state at room temperature. After cooling, take 100 grams of solid After grinding with 0.01g of azodicarbonamide to form a powder, it is put into a pre-heated mold and foamed at 180°C. After 30 minutes, the oven temperature is reduced to 150°C. After keeping it for 3 hours, it is naturally cooled to room temperature. mold.

[0028] Experimental results: such as Figure 6~Figure 7 As shown, by adding a small amount of blowing agent, the cell density of the material is lower, and the apparent density is 1.1 g / cm 3 , And the cell diameter is about 15μm.

Embodiment 3

[0030] 100 grams of epoxy resin, 80 grams of curing agent, 0.1 grams of curing aid, 5 grams of nano-montmorillonite, 10 grams of nano-silica, 2 grams of diepoxypentyl ether dioxide, added to the reactor and reacted to room temperature The system is in a solid state. After cooling, take 100 g of solid and 0.5 g of 4,4-oxobisphenylsulfonyl hydrazide and grind it into a powder, then put it in a pre-heated mold and foam at 150°C and keep it warm for 3 hours. Naturally cool to room temperature and demould.

[0031] Experimental results: such as Figure 8~Figure 9 As shown, the apparent density of the foamed material is 0.8 g / cm 3 , The cell diameter is about 50μm.

[0032] In the present invention, mechanical milling (ball mill) is used to grind to obtain powder, and powder epoxy resins with different particle diameters can be obtained by rotating speed and time. It should be noted that the grinding process cannot be continuously milled for a long time. Intermittent milling method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com