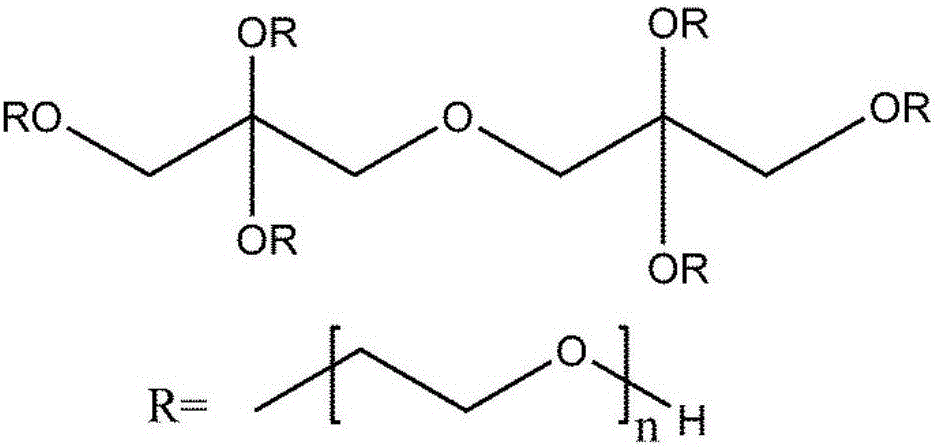

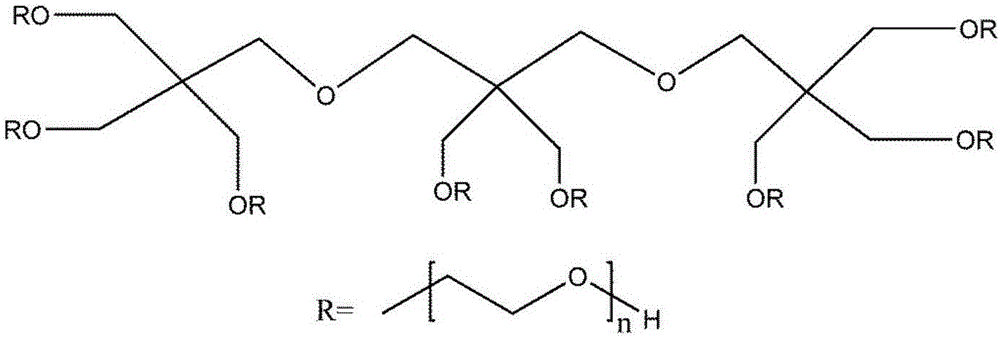

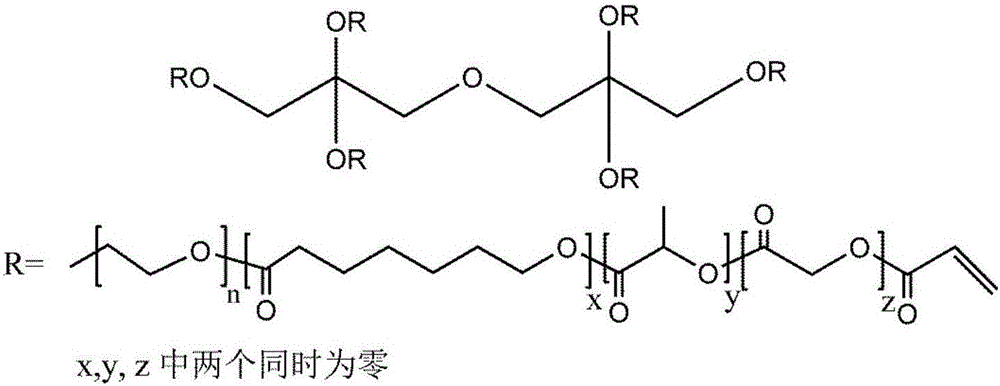

Low-swelling biodegradable medical photopolymeric aquagel and preparation method thereof

A biodegradable and photopolymerizable technology, which is applied in the direction of non-active ingredient medical preparations, pharmaceutical formulations, drug delivery, etc., can solve the problems of low strength and large gel swelling ratio, and achieve low swelling ratio and low swelling rate , the effect of avoiding adverse consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Preparation of polyester modified six-arm polyethylene glycol block copolymer

[0060] Put 100g of six-armed polyethylene glycol (molecular weight: 6000) into a vacuum reaction flask, remove water under reduced pressure at 100°C for 2 hours, cool to room temperature, and equilibrate with dry nitrogen, add 11.40g of caprolactone and 0.3g of stannous octoate. After vacuum deoxygenation, the reaction was carried out at a vacuum degree of 10 Pa and a temperature of 115°C for 12 hours. The crude product was dissolved in 50 mL of anhydrous dichloromethane, precipitated with glacial ether, filtered, and vacuum-dried at room temperature to constant weight to obtain a polyester-modified six-arm poly Ethylene glycol block copolymer.

[0061] (2) Preparation of acrylate-terminated polyester modified six-arm polyethylene glycol

[0062] Dissolve 50g of polyester-modified six-arm polyethylene glycol and 4.54g of triethylamine in 30mL of anhydrous dichloromethane, cool down to 0...

Embodiment 2

[0066] (1) Preparation of polyester modified six-arm polyethylene glycol block copolymer

[0067] Put 150g of six-armed polyethylene glycol (molecular weight: 10000) into a vacuum reaction bottle, remove water under reduced pressure at 100°C for 2 hours, cool to room temperature, and equilibrate with dry nitrogen, add 20.52g of caprolactone and 0.4g of stannous octoate. After vacuum deoxygenation, react at a vacuum degree of 20 Pa and a temperature of 125°C for 12 hours. The crude product is dissolved in 80 mL of anhydrous dichloromethane, precipitated with glacial ether, filtered, and vacuum-dried at room temperature to constant weight to obtain a polyester-modified six-arm poly Ethylene glycol block copolymer.

[0068] (2) Preparation of acrylate-terminated polyester modified six-arm polyethylene glycol

[0069] Dissolve 50g of polyester-modified six-arm polyethylene glycol and 5.34g of triethylamine in 25mL of anhydrous dichloromethane, cool down to 0°C, and slowly add 4.7...

Embodiment 3

[0073] (1) Preparation of polyester modified six-arm polyethylene glycol block copolymer

[0074] Put 200g of six-armed polyethylene glycol (molecular weight: 15000) into a vacuum reaction bottle, remove water under reduced pressure at 100°C for 2 hours, cool to room temperature, and equilibrate with dry nitrogen, add 27.36g of caprolactone and 0.35g of stannous octoate. After vacuum deoxygenation, react at a vacuum degree of 10 Pa and a temperature of 135°C for 12 hours. The crude product is dissolved in 120 mL of anhydrous dichloromethane, precipitated with glacial ether, filtered, and vacuum-dried at room temperature to constant weight to obtain a polyester-modified six-arm poly Ethylene glycol block copolymer.

[0075] (2) Preparation of acrylate-terminated polyester modified six-arm polyethylene glycol

[0076] Dissolve 50g of polyester-modified six-arm polyethylene glycol and 3.56g of triethylamine in 25mL of anhydrous dichloromethane, cool down to 0°C, and slowly add 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com