Copper-aluminum cold pressure welding process for refrigerator evaporator

A technology for evaporators and refrigerators, applied in non-electric welding equipment, applications, household appliances, etc., can solve the problems of many process parameters, difficult to control, complex equipment, etc., and achieve the effect of simple process, easy operation, and few welding parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

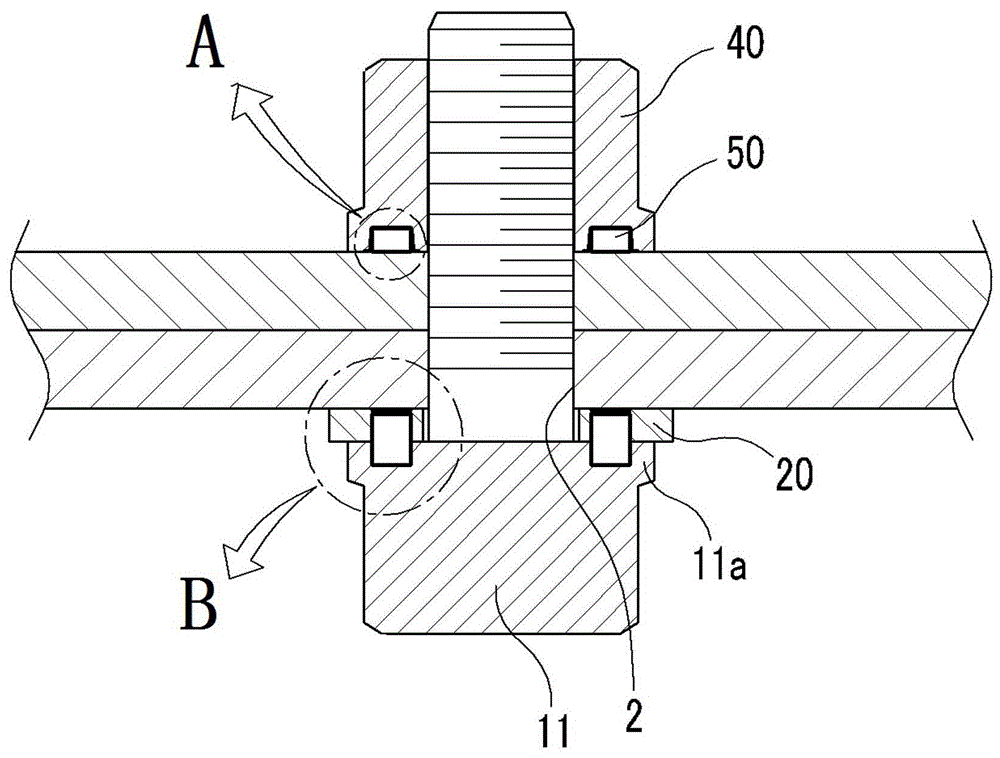

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

[0027] The copper-aluminum tube cold pressure welding process for the refrigerator evaporator is composed of the following parts:

[0028] 1. Processing of weldments

[0029] Before welding, the annealed copper tube and aluminum tube should be processed into end faces to be welded after chemical treatment, and the end faces of copper tubes to be welded are grooved along the outer diameter. Grind the metal surface of the welding area with a rotating wire brush, clean the small mandrel made of hard aluminum wire with acetone or gasoline, and place it in the copper tube and aluminum tube with pliers; use the positioning rod to position the mandrel on the copper tube. position in the tube. Put the copper tube and aluminum tube into the clamp of the cold press welding machine, and pull out the positioning rod.

[0030] 2. Cold pressure welding

[0031] Start the cold press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com