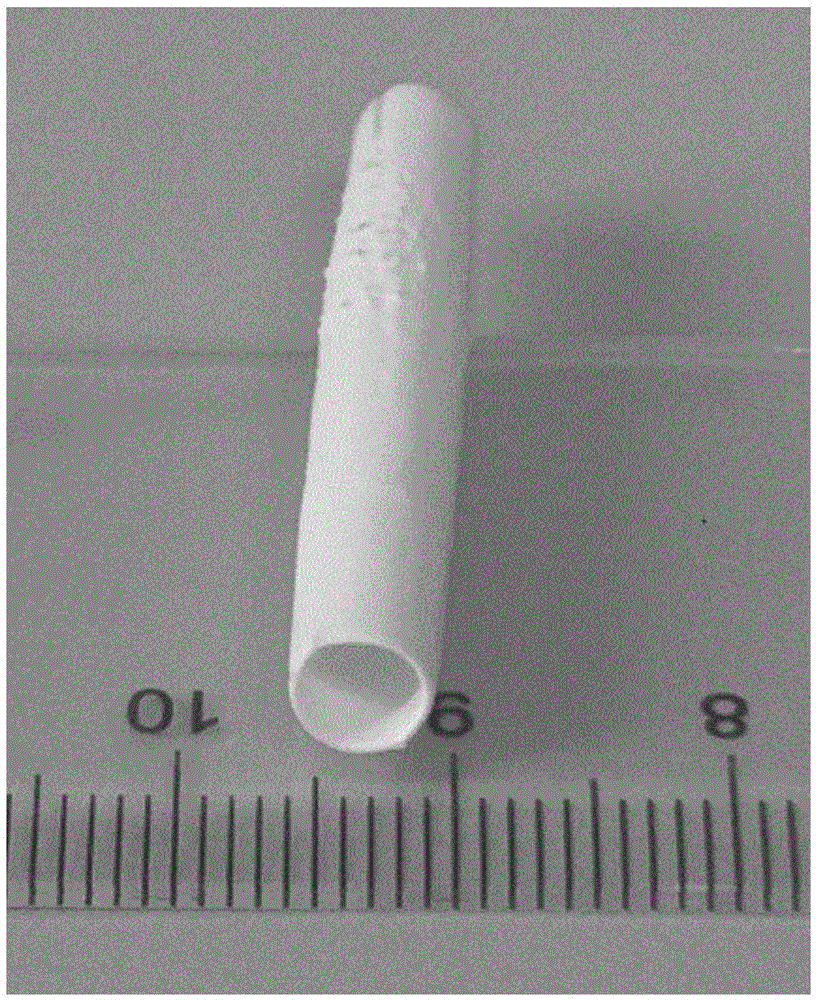

Natural-blood-vessel-simulating three-layer artificial blood vessel stent and preparation method thereof

An artificial blood vessel, imitating nature technology, applied in non-woven fabrics, textiles, papermaking, medical science, etc., to achieve the effect of narrow fiber diameter distribution range, simple equipment, and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

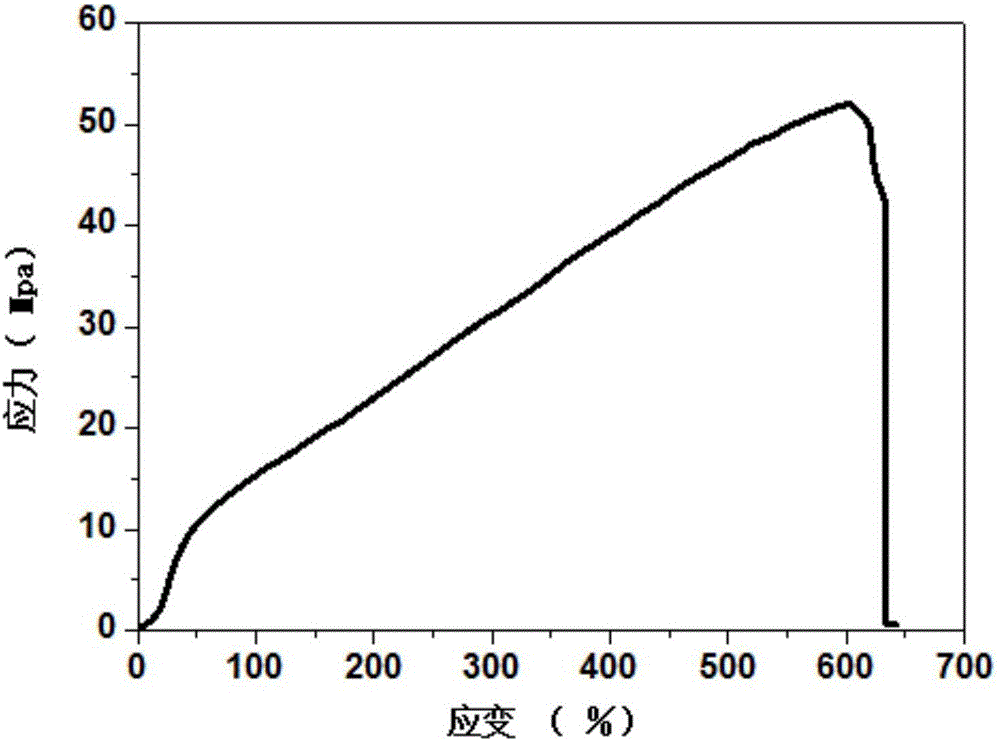

Examples

Embodiment 1

[0035] The first step, polymer A is selected as polycaprolactone (PCL, (C 6 h 10 o 2 ) n ) and polylactic acid (PLA, (C 6 h 8 o 4 ) n ) is mixed in a mass ratio of 3:7 and dissolved in a mixed solvent, and is prepared into a spinning solution with a concentration of 10% by mass percentage, that is, a spinning solution of polymer A, for preparing the M layer; in the mixed solvent, acetone and The mass ratio of N,N-dimethylformamide w / w=1:5.

[0036] Polymer B is selected as dissolving PU-PCL (mass ratio 3:1) in a mixed solvent of DMF and THF to prepare a spinning solution of polymer B with a mass percentage of 10%, which is used to prepare the N layer. The mass ratio of DMF and THF in the mixed solvent is 3:1.

[0037] In the second step, the spinning solution of polymer A is placed in a syringe pump with a needle with a diameter of 0.8 mm, a voltage of 10-15 kV is applied, and electrospinning is carried out for 1 hour when the working distance is 10-15 cm. A rotating mo...

Embodiment 2

[0043] In the first step, polymer A is selected as polylactic acid (PLA, (C 6 h 8 o 4 ) n ), polymer A is dissolved in the mixed solvent, is formulated with the spinning solution of the polymer A of 15wt% concentration, is used to prepare M layer fiber film; In the mixed solvent, acetone and N,N-dimethylformamide The mass ratio w / w=1:1.

[0044] Polymer B is selected as pure polyurethane (PU, C 28 h 44 N 2 o 11 ), polymer B was dissolved in DMF and THF to make a spinning solution of 10% polymer B by mass percentage. Wherein, the mass ratio of DMF and THF is 1:3.

[0045] In the second step, the spinning solution of polymer A is placed in a syringe pump equipped with a needle with a diameter of 1.0mm, and a voltage of 15kV is applied to carry out electrospinning when the working distance is 15cm, and the rotational speed of the rotating motor for receiving fibers is 60r / min , to obtain an inner layer fiber membrane with excellent mechanical properties and a porosity of...

Embodiment 3

[0051] In the first step, the polymer A is selected as silk fibroin, and the polymer A is dissolved in ethanol to form a spinning solution of 8% by mass of the polymer A;

[0052] Polymer B is selected as polycaprolactone (PCL, (C 6 h 10 o 2 ) n ), a mixture of polylactic acid-glycolic acid copolymer (PLGA, 75:25), wherein the mass ratio of PCL to PLGA is 3:7. Polymer B was dissolved in a mixed solvent to prepare a spinning solution with 15% by mass of polymer B. The mass percentage w / w of acetone and N,N-dimethylformamide in the mixed solvent is 1:4.

[0053] In the second step, the spinning solution of polymer A is placed in a syringe pump equipped with a needle with a diameter of 1 mm, and a voltage of 10 kV is applied to perform electrospinning at a working distance of 15 cm. The spinning time is 0.5 h. The rotating motor of the tube collects the fibers to prepare the inner fibrous layer of the three-layer vascular stent. The rotational speed of the rotary motor is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com