Hybrid power circulating system, operating method of hybrid power circulating system and power generation system

A cycle system and composite power technology, which is applied in the field of a composite power cycle system and its operation method and power generation system, can solve the problems of not being effectively utilized, the cost of the power generation system rising, and the power being difficult to be absorbed by the power grid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail below with reference to specific embodiments, but it is not intended to limit the present invention. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. In addition, specific features, structures, or characteristics in one or more embodiments may be combined in any suitable form.

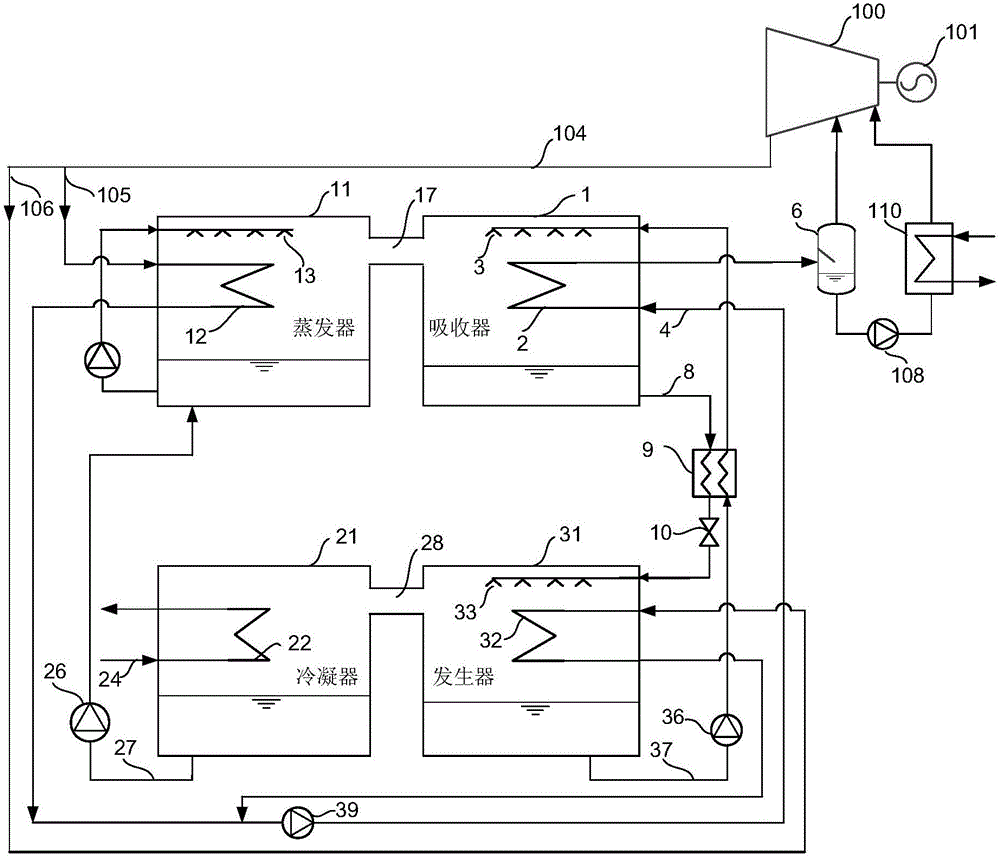

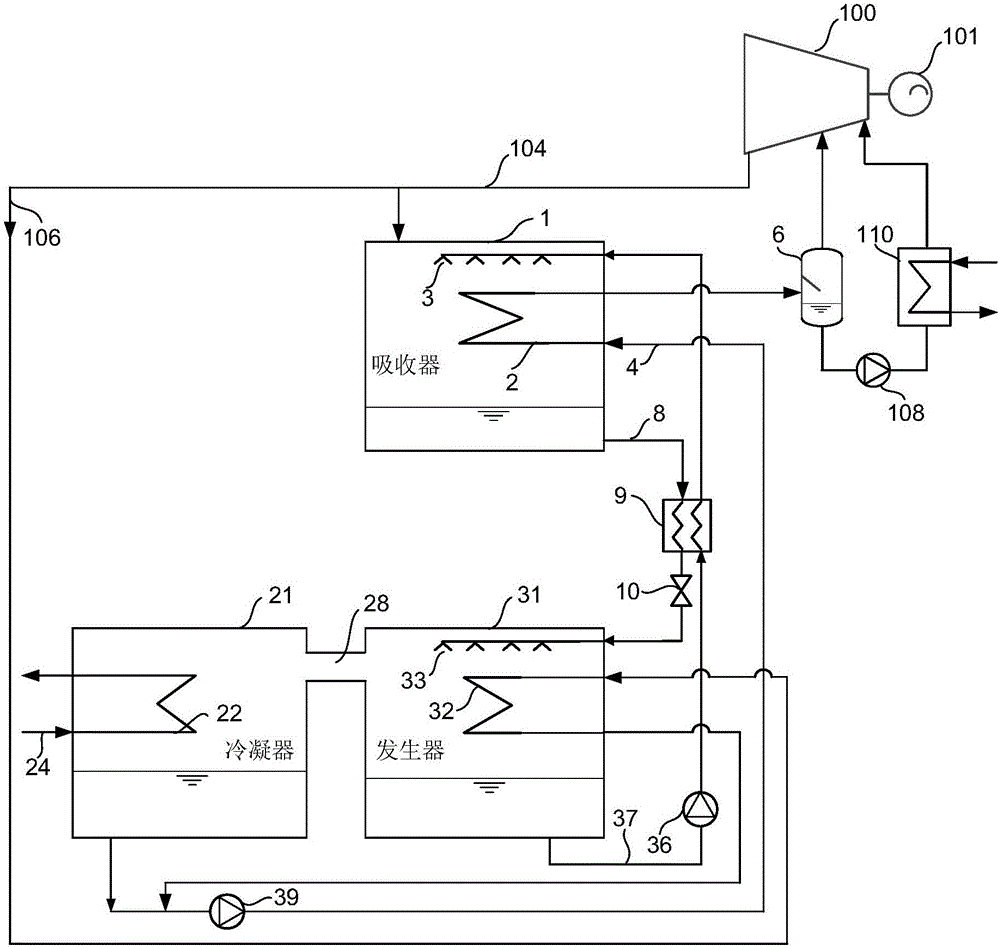

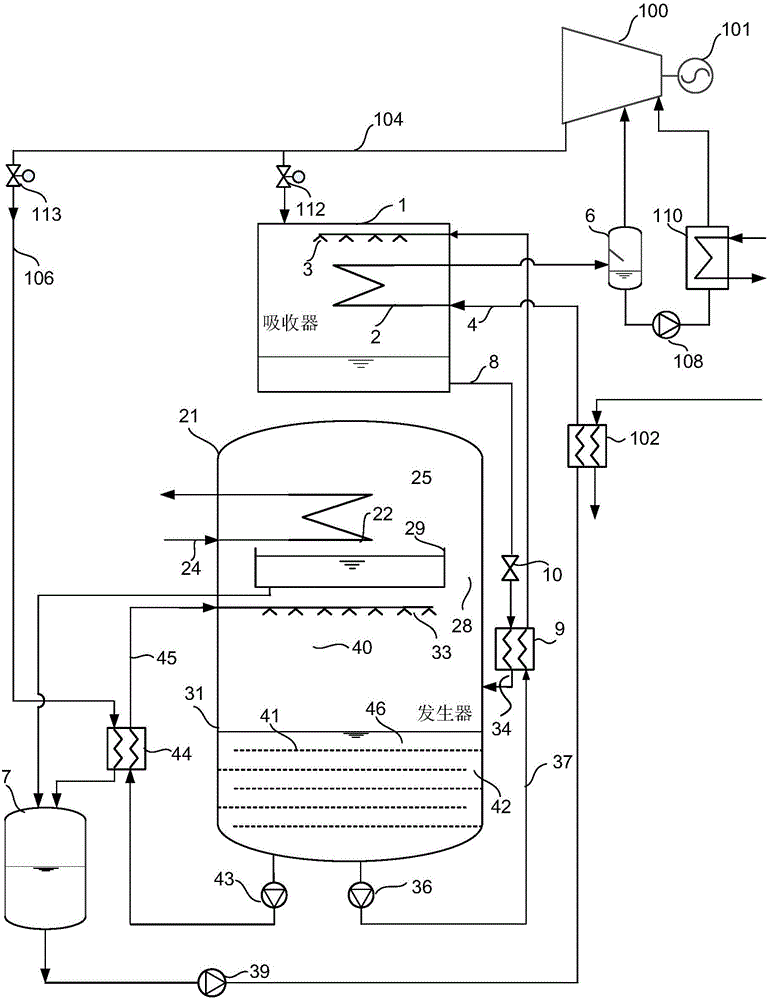

[0073] Figure 1 to Figure 6 They are respectively structural schematic diagrams of different embodiments of the compound power cycle system of the present invention. See Figure 1 to Figure 6 , Compound power cycle system, including power subsystem and absorption heat pump subsystem, among which

[0074] The power subsystem includes a condensing working fluid booster pump 108, a high-pressure steam generator 110 and a steam power plant 100;

[0075] The absorption heat pump subsystem includes an absorber 1, a generator 31, and a condenser 21. The absorber 1 includes an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com