Blackening method of lithium tantalate crystal substrate

A treatment method, lithium tantalate technology, applied in chemical instruments and methods, after treatment, crystal growth, etc., can solve the problems of Sumitomo's difficult control of process conditions, potential safety hazards, and Shin-Etsu's complex process, so as to improve the discharge phenomenon, Improved precision, easy control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

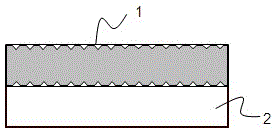

[0032] This embodiment provides a blackening treatment method for a lithium tantalate crystal substrate. The surface of the metal sheet 1 is roughened by wet etching, and hydrofluoric acid, nitric acid or a mixture of the two is used for roughening by wet etching. The wet etching temperature is 20-80° C., and the wet etching time of the metal sheet is 3-10 minutes. The surface roughness Ra of the metal sheet 1 after treatment is 0.1 ~ 10um, refer to figure 1 In the cavity, the roughened metal sheet 1 and the lithium tantalate crystal substrate 2 are alternately stacked in a contact manner, wherein the material of the metal sheet 1 can be Al, Ti, Zn or Fe, and the material of the metal sheet 1 is preferably Al , the thickness D of the metal sheet 1 is 0.05-20 mm, placed in an environment lower than the Curie temperature, and the lithium tantalate crystal substrate 2 is reduced. Specifically, the ambient temperature during blackening treatment is 350-600°C, and the treatment t...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that the surface of the lithium tantalate crystal substrate 2 is roughened, and the roughening is carried out by wet etching with hydrofluoric acid, nitric acid or a mixture of the two, and the wet etching temperature is Between 20 and 80 degrees Celsius, the wet etching time for the metal sheet is 3 to 10 minutes, and the wet etching time for the lithium tantalate crystal substrate is 3 to 10 hours. The surface roughness Ra of lithium tantalate crystal substrate 2 after treatment is 0.1~10um, see Figure 4 , stacking the roughened lithium tantalate crystal substrate 2 and the unroughened metal sheet 1 for reduction treatment.

[0037] Compared with the prior art, after the lithium tantalate crystal substrate is ground, a better flatness is obtained and then the reduction reaction is performed. The reduction reaction performance of the roughened lithium tantalate crystal substrate is better than that after grind...

Embodiment 3

[0040] According to the prior art, most of the current blackening processes are carried out after slicing. In combination with Embodiment 1 and Embodiment 2, this embodiment proposes a technical solution for roughening the metal sheet 1 and the lithium tantalate crystal substrate 2 respectively. Roughening is carried out by wet etching with hydrofluoric acid, nitric acid or a mixture of the two. The wet etching temperature is between 20~80°C. The wet etching time of the metal sheet is 3~10 minutes. Lithium tantalate The wet etching time of the crystal substrate is 3-10 hours. After roughening, the surface roughness Ra of the metal sheet 1 and the lithium tantalate crystal substrate 2 is 0.1-10 um.

[0041] see Figure 7 In the cavity, the roughened metal sheet 1 and lithium tantalate crystal substrate 2 are alternately stacked in a contact manner, wherein the material of the metal sheet 1 can be Al, Ti, Zn or Fe, and the thickness D of the metal sheet 1 is 0.05 ~20mm, place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com