Extra-dark PC/ABS alloy material and preparation method thereof

An alloy material, special black technology, applied in the field of special black PC/ABS alloy material and its preparation, can solve the problems of dust pollution, human body harm, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

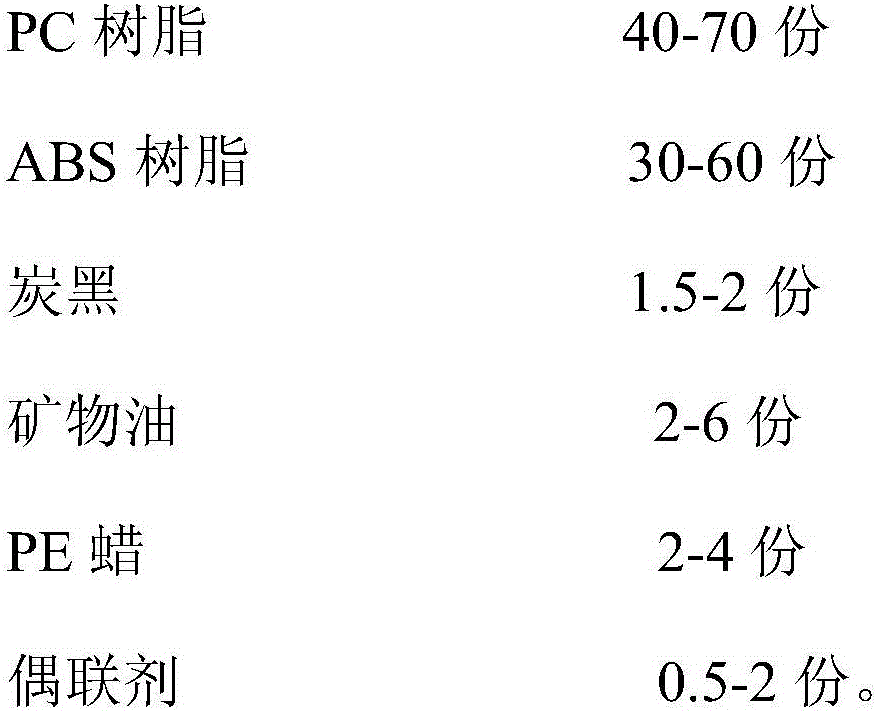

Embodiment 1

[0074]According to the ratio of raw materials (see Table 1), mix PC resin, ABS resin, PE wax, mineral oil, antioxidant, lubricant and coupling agent in a high-speed mixer, and blend for 2 minutes at a speed of 750r / min ; Add carbon black to it, and continue blending for 3 minutes at a rotating speed of 1500r / min; join the obtained mixture into a twin-screw extruder for extrusion, and carry out melt co-extrusion through nine hot zones in turn, and set the twin-screw The speed of the extruder is 250r / min, the temperature of the first zone is 210°C, the temperature of the second zone is 230°C, the temperature of the third zone is 245°C, the temperature of the fourth zone is 255°C, the temperature of the fifth zone is 265°C, and the temperature of the sixth zone is 270 ℃, the temperature in the seventh zone is 265℃, the temperature in the eighth zone is 250℃, the temperature in the ninth zone is 245℃, co-extrude for 1min; extrude the mixture after melt co-extrusion, cool, dry and p...

Embodiment 2

[0076] According to the ratio of raw materials (see Table 1), mix PC resin, ABS resin, PE wax, mineral oil, antioxidant, lubricant and coupling agent in a high-speed mixer, and blend for 3 minutes at a speed of 800r / min Add carbon black to it, and continue blending for 5 minutes at a speed of 1600r / min; join the obtained mixture into a twin-screw extruder, and carry out melt co-extrusion through nine hot zones in turn, and set the twin-screw extrusion The speed of the machine is 350r / min, the temperature of the first zone is 230°C, the temperature of the second zone is 245°C, the temperature of the third zone is 255°C, the temperature of the fourth zone is 265°C, the temperature of the fifth zone is 270°C, and the temperature of the sixth zone is 275°C. The temperature of zone 7 is 270°C, the temperature of zone 8 is 265°C, the temperature of zone 9 is 260°C, co-extrude for 3 minutes; extrude the melt-blended mixture, cool, dry, and pelletize to obtain extra black PC / ABS Alloy...

Embodiment 3

[0078] According to the ratio of raw materials (see Table 1), PC resin, ABS resin, PE wax, mineral oil, antioxidant, lubricant and coupling agent are mixed in a high-speed mixer, and blended at a speed of 780r / min for 2.5 min; add carbon black to it, and continue blending for 4min at a speed of 1550r / min; add the obtained mixture into a twin-screw extruder, and carry out melt co-extrusion through nine hot zones in turn, and set the twin-screw extrusion The output speed is 300r / min, the temperature in the first zone is 220°C, the temperature in the second zone is 240°C, the temperature in the third zone is 250°C, the temperature in the fourth zone is 260°C, the temperature in the fifth zone is 265°C, and the temperature in the sixth zone is 270°C , the temperature in zone 7 is 275°C, the temperature in zone 8 is 260°C, the temperature in zone 9 is 255°C, and blended for 3 minutes; the mixture after melt blending is extruded, cooled, dried, and pelletized to obtain extra black PC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com