A device for adjusting and controlling the position of a horizontal roll

An adjustment control, horizontal roller technology, applied in the direction of grinding drive device, grinding/polishing safety device, manufacturing tools, etc., can solve the problem that the quality of strip steel cannot meet the specified requirements, restrict the quality of the unit, and re-grind the strip steel, etc. problem, to achieve the effect of simple structure, improved grinding quality, and reduced grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

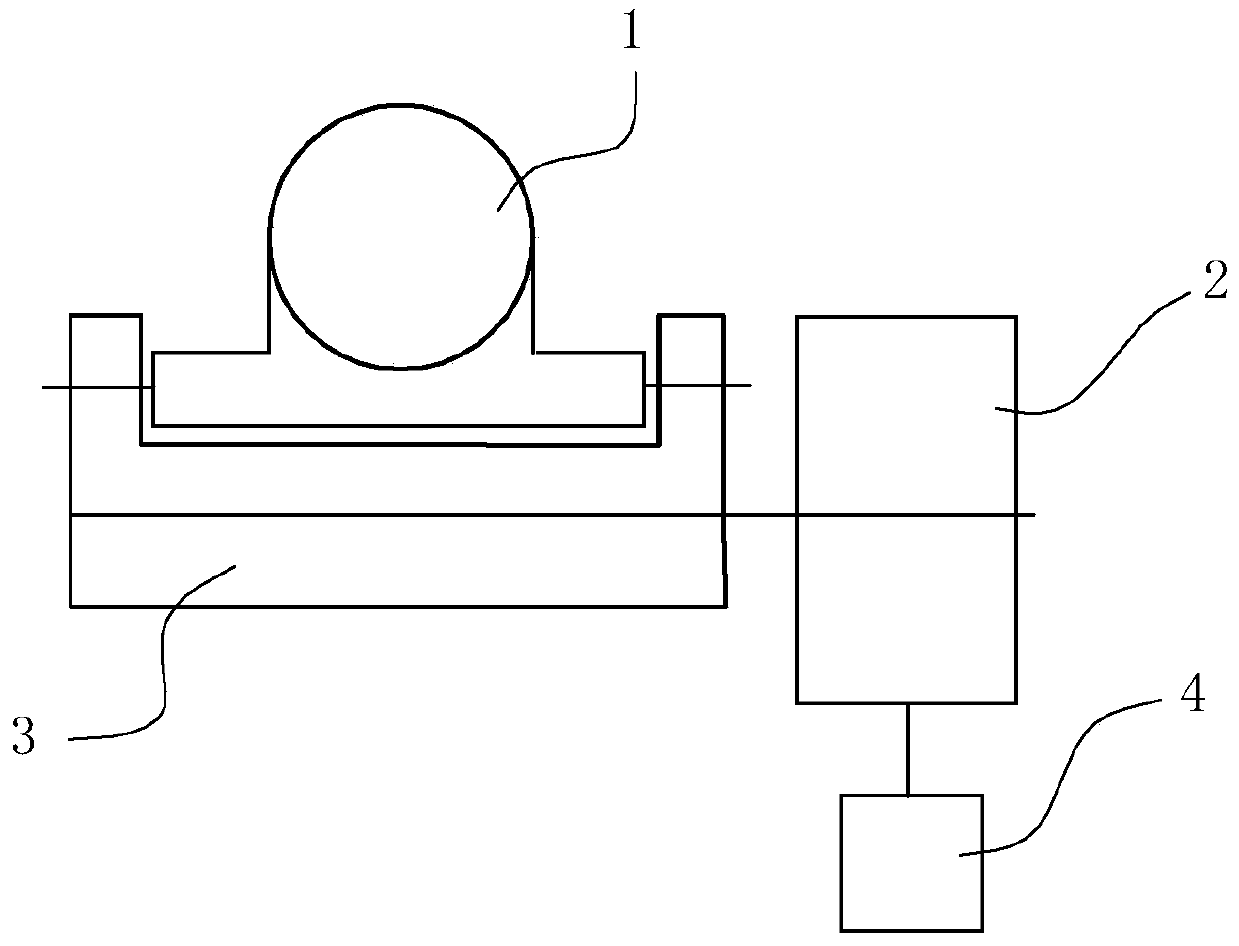

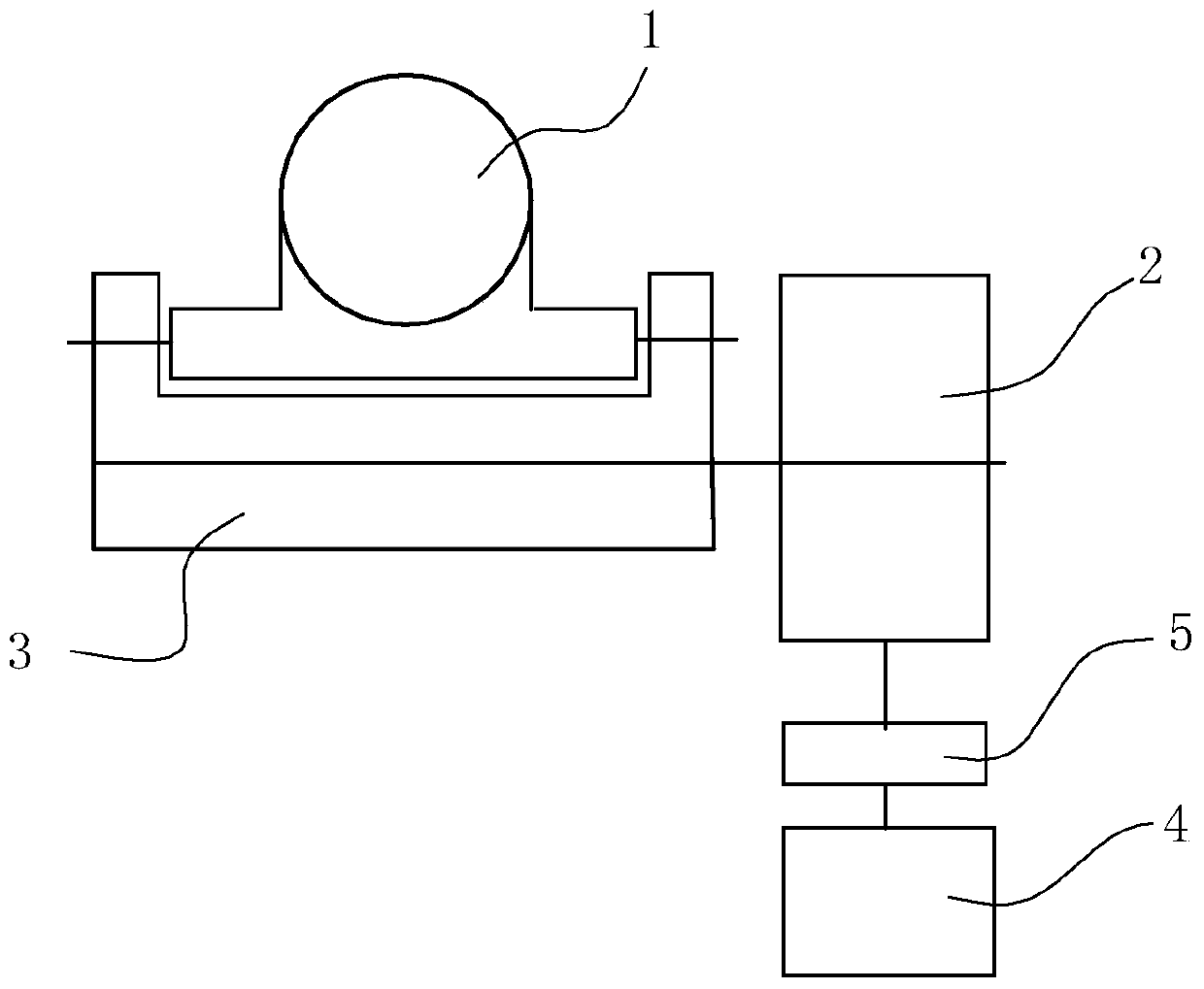

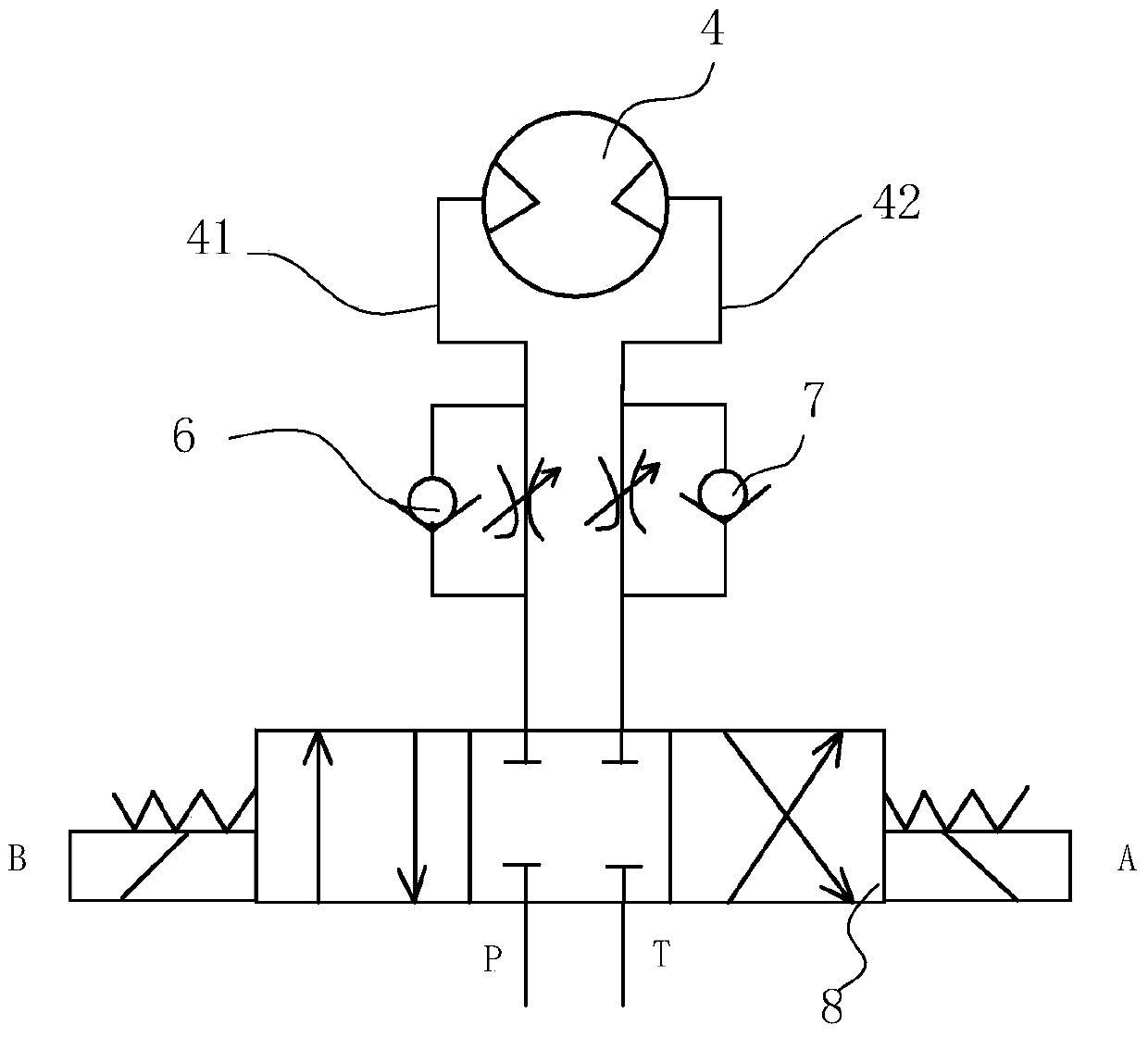

[0020] figure 1 , 3 It is the horizontal roller position adjustment mechanism before improvement, including horizontal roller 1, eccentric mechanism 3, worm gear mechanism 2, hydraulic motor 4 and hydraulic control unit, the horizontal roller position adjustment mechanism is driven by hydraulic motor 4, and hydraulic motor 4 is driven by the transmission shaft The worm is driven by the rotation of the worm wheel, and then the eccentric shaft of the eccentric mechanism 3 is driven by the rotation of the worm wheel, so as to realize the micro movement of the bearing seat of the horizontal roller up and down, thereby realizing the adjustment and control of the position of the horizontal roller 1. However, during the grinding process, the steel strip has a downward force on the horizontal roller 1, which will cause the position of the eccentric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com