Degreasing agent of polymer flooding produced wastewater and preparation method of degreasing agent

A technology of degreasing agent and polymer, which is applied in the field of degreasing agent and its preparation of sewage produced by polymer flooding, and can solve the problems of unsuitable degreasing treatment of sewage containing polymer, complex and changeable operation methods, poor demulsification effect, etc. problem, to achieve high degreasing efficiency, improve degreasing efficiency and reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Degreaser C 1 and its preparation method

[0031] (1) Degreaser C 1 The composition and components are as follows:

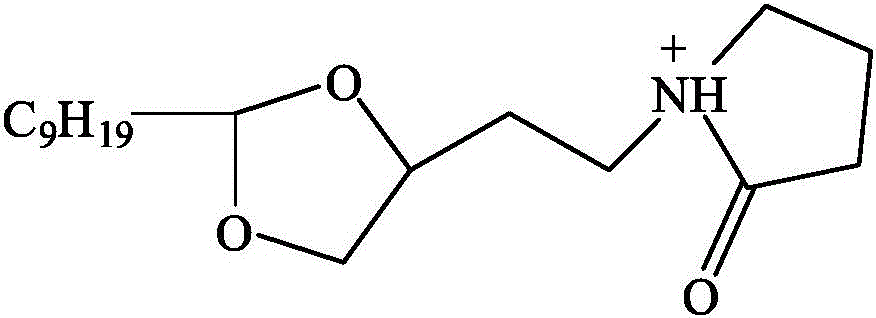

[0032] The degreasing agent is formed by reacting n-decyl aldehyde with epoxybromobutane under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacting with pyrrolidone to form a cationic degreasing agent. Its molecular formula is as follows:

[0033]

[0034] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and pyrrolidone is 1.0:0.5:0.5.

[0035] (2) Degreaser C 1 The preparation method is as follows:

[0036] ①Put a three-neck flask with a stirring rod into a water bath, add 1mol of n-decyl aldehyde, then add 2340g of acetonitrile, heat up to 35°C, stir at a stirring rate of 350rpm for 25min, then add 0.156g of acetonitrile with a mass concentration of 30% Put 0.5mol epoxybromobutane in the constant pressure dropping funnel, control the dropping rate to 3 drops / min, raise the tempe...

Embodiment 2

[0039] Embodiment 2: Degreaser C 2 and its preparation method

[0040] (1) Degreaser C 2 The composition and components are as follows:

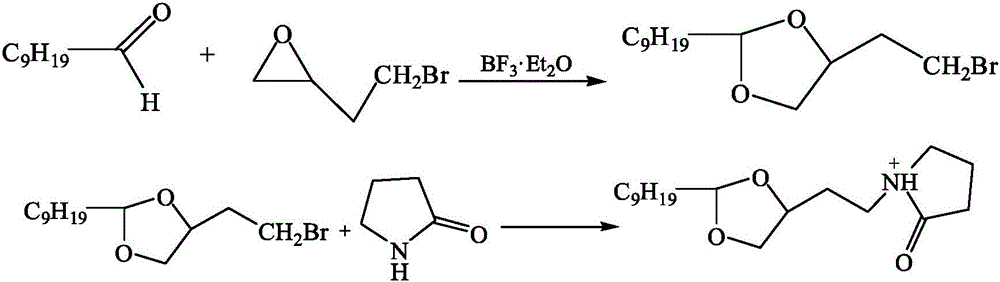

[0041] The degreasing agent is formed by reacting n-decyl aldehyde with epoxybromobutane under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacting with pyrrolidone to form a cationic degreasing agent. Its molecular formula is as follows:

[0042]

[0043] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and pyrrolidone is 1.0:1.0:1.1.

[0044](2) Degreaser C 2 The preparation method is as follows:

[0045] ①Put a three-necked flask with a stirring rod into a water bath, add 1mol of n-decyl aldehyde, then add 3250g of acetonitrile, heat up to 40°C, stir at a stirring rate of 250rpm for 15min, then add 0.54g of 30% mass concentration Put 1.0mol epoxybromobutane into the constant pressure dropping funnel, control the dropping rate to 3 drops / min, raise the temperature to 62°C, stir ...

Embodiment 3

[0048] Embodiment 3: Degreaser C 3 and its preparation method

[0049] (1) Degreaser C 3 The composition and components are as follows:

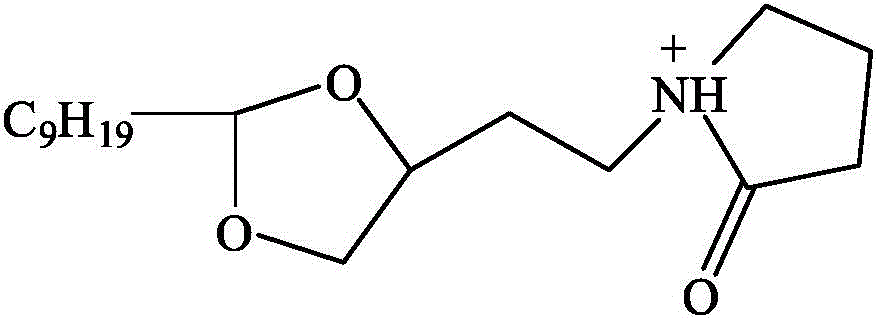

[0050] The degreasing agent is formed by reacting n-decyl aldehyde with epoxybromobutane under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacting with pyrrolidone to form a cationic degreasing agent. Its molecular formula is as follows:

[0051]

[0052] Wherein, the molar ratio of n-decyl aldehyde, epoxybromobutane and pyrrolidone is 1:1.25:1.5.

[0053] (2) Degreaser C 3 The preparation method is as follows:

[0054] ①Put a three-necked flask with a stirring bar into a water bath, add 1mol of n-decyl aldehyde, then add 3900g of acetonitrile, heat up to 50°C, stir for 40min at a stirring rate of 400rpm, and then add 0.78g of acetonitrile with a mass concentration of 30% Put 1.25mol epoxybromobutane in the constant pressure dropping funnel, control the dropping rate to 4 drops / min, raise the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com