Method for producing tobermorite by conducting microwave heating on siliceous waste and carbide slag

A technology of microwave heating and tobermorite, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problem of not being suitable for the preparation of high-performance insulation materials and adsorbent materials, high production energy consumption and cost, resources and the environment Large impact and other problems, to achieve the effect of high crystallinity, no impurities in the phase, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

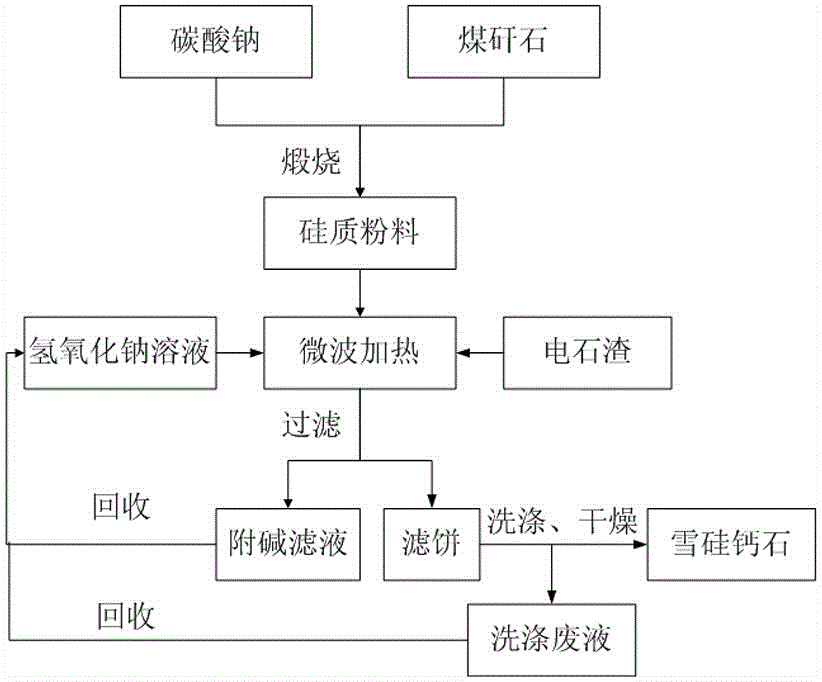

[0040] Tobermorite is produced by microwave heating of coal gangue and calcium carbide slag, wherein the coal gangue contains 54.06% SiO 2 , 13.64% Al 2 o 3 , 2.67% CaO, 8.09% Fe 2 o 3 and 1.06% Na 2 O; Carbide slag contains 60% CaO, 4.34% SiO 2 , 2.24% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: combine coal gangue and sodium carbonate with Na 2 CO 3 / SiO 2 The molar ratio is 0.5:1 for batching, the calcination activation temperature is 600°C, and the calcination time is 1h to obtain siliceous powder; the siliceous powder, calcium carbide slag and a mass concentration of 3% sodium hydroxide solution are mixed with Si:Ca: The molar ratio of Na is 1:0.75:1.6. After mixing evenly, microwave heating to 90°C and keep it warm for 4 hours; after the reaction is completed, filter the mixed slurry to obtain filter cake and alkali filtrate, wash the filter cake and dry at 100°C for 3 hours To obtain tobermanite; the filter cake ...

Embodiment 2

[0043] Tobermorite is produced by microwave heating of coal gangue and calcium carbide slag, wherein the coal gangue contains 56.86% SiO 2 , 12.74% Al 2 o 3 , 2.37% CaO, 7.68% Fe 2 o 3 and 1.36% Na 2 O; Carbide slag contains 59.3% CaO, 4.64% SiO 2 , 2.34% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: combine coal gangue and sodium carbonate with Na 2 CO 3 / SiO 2 The molar ratio is 0.4:1 for batching, the calcination activation temperature is 700°C, and the calcination time is 1h to obtain siliceous powder; the siliceous powder, calcium carbide slag and sodium hydroxide solution with a mass concentration of 4% are mixed with Si:Ca :Na molar ratio is 1:0.8:1.4 ingredients, after mixing evenly, microwave heating to 120°C and heat preservation reaction for 3h; after the reaction is completed, filter the mixed slurry to obtain filter cake and alkali filtrate, wash the filter cake and dry at 90°C 3h to obtain tobermorite; the f...

Embodiment 3

[0046] Tobermorite is produced by microwave heating of coal gangue and calcium carbide slag, wherein the coal gangue contains 52.75% SiO 2 , 15.31% Al 2 o 3 , 2.16% CaO, 7.29% Fe 2 o 3 and 1.91% Na 2 O; Carbide slag contains 63.3% CaO, 4.64% SiO 2 , 2.34% Al 2 o 3 and a small amount of MgO and Fe 2 o 3 . Process steps such as figure 1 Shown: combine coal gangue and sodium carbonate with Na 2 CO 3 / SiO 2 The molar ratio is 0.45:1 for batching, the calcination activation temperature is 650°C, and the calcination time is 2h to obtain siliceous powder; the siliceous powder, calcium carbide slag and a mass concentration of 2% sodium hydroxide solution are mixed with Si:Ca: The molar ratio of Na is 1:0.85:1.5. After mixing evenly, microwave heating to 140°C and heat preservation reaction for 3h; after the reaction is completed, filter the mixed slurry to obtain filter cake and alkali filtrate, wash the filter cake and dry at 100°C for 3h To obtain tobermanite; the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com